3238

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

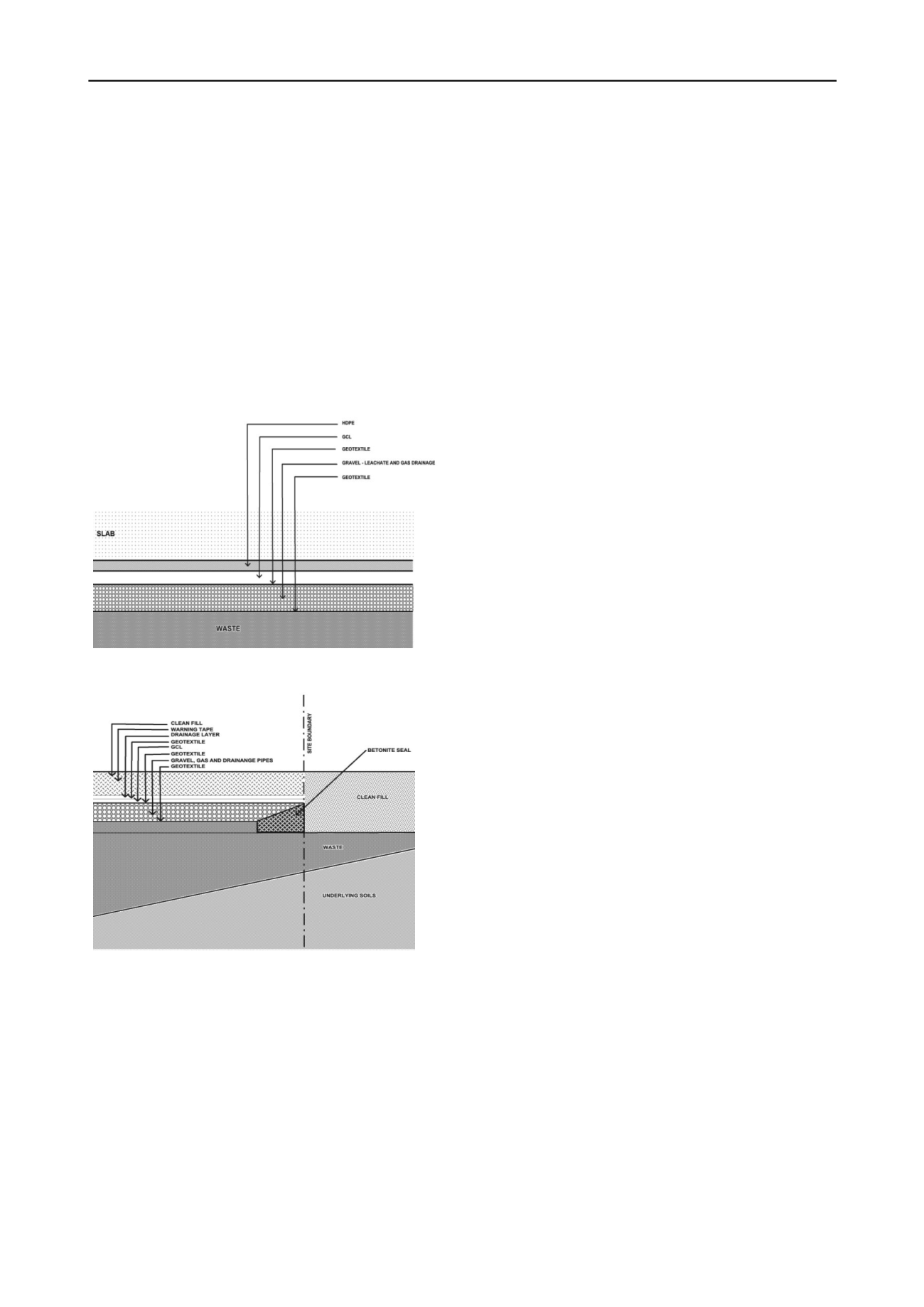

extent 50 m beyond the landfill boundary or the site boundary

whichever occurs first. At the landfill boundary within the site,

the capping will be keyed in with a sump installed for leachate

and landfill gas condensate collection.

7 LESSONS LEARNT DURING CONSTRUCTION

Where the landfill extends over the site boundary a bentonite

plug will be installed at the boundary to minimise migration of

landfill gases through soils, refer to Figure 6.

Of particular interest to those wanting to apply the techniques

described in this paper for another site or project, are the lessons

learnt during the construction of this project. Primarily, these

are as follows:

Landfill gas drainage will consist of a gas drainage layer

forming part of the cap. Collection pipes will be placed around

the perimeter and across the benches with a maximum spacing

of 50 m. An additional gas extraction filter layer and pipe work

for the collection and discharge of LFG will be incorporated

beneath the slab of all buildings where possible. Three remedial

options for the management landfill gas were considered. The

use of landfill gas for power generation was not considered

feasible due to low gas flows as result of the age and stage of

the decomposition of the waste present at the site this option

1. The site was located within 50m of a main highway. A

hazard was ‘fly rock’ being mobilized during dynamic

compaction and hitting operators or leaving the site and

colliding with a vehicle on the highway. To control this

hazard, a no-go zone was established around the dynamic

compaction rig and the rig was not allowed to operate

near the highway.

2. The extent of consolidation during dynamic compaction was

significant. At this site, the contaminated water make

during dynamic compaction was also significant. Whilst

this was predicted and readily catered for onsite (in

accordance with the CEMP) it took a considerable amount

of time to manage, sample for contamination and then

subsequently discharge at an appropriate location. It was

also relatively expensive.

3. The use of coal washery rejects, a mining by-product from

the coal washing process, was entirely successful. This

material was put to use on this site and would otherwise

have ended up as landfill. The ability to use what would

otherwise have been waste material, as fill material in the

overall remediation of another landfill site, is considered

best

practice

and

an

outstanding

outcome

environmentally.

4. The selection of an earthworks contractor must include an

assessment of their ability to perform the work rapidly.

Exposing the waste sections of the site created many

hazards, and the contractors ability to perform the work

and ‘cap’ the site ready for dynamic compaction in the

shortest possible timeframe greatly reduces the exposure

to those hazards and any expensive delays caused by (for

example) inclement weather.

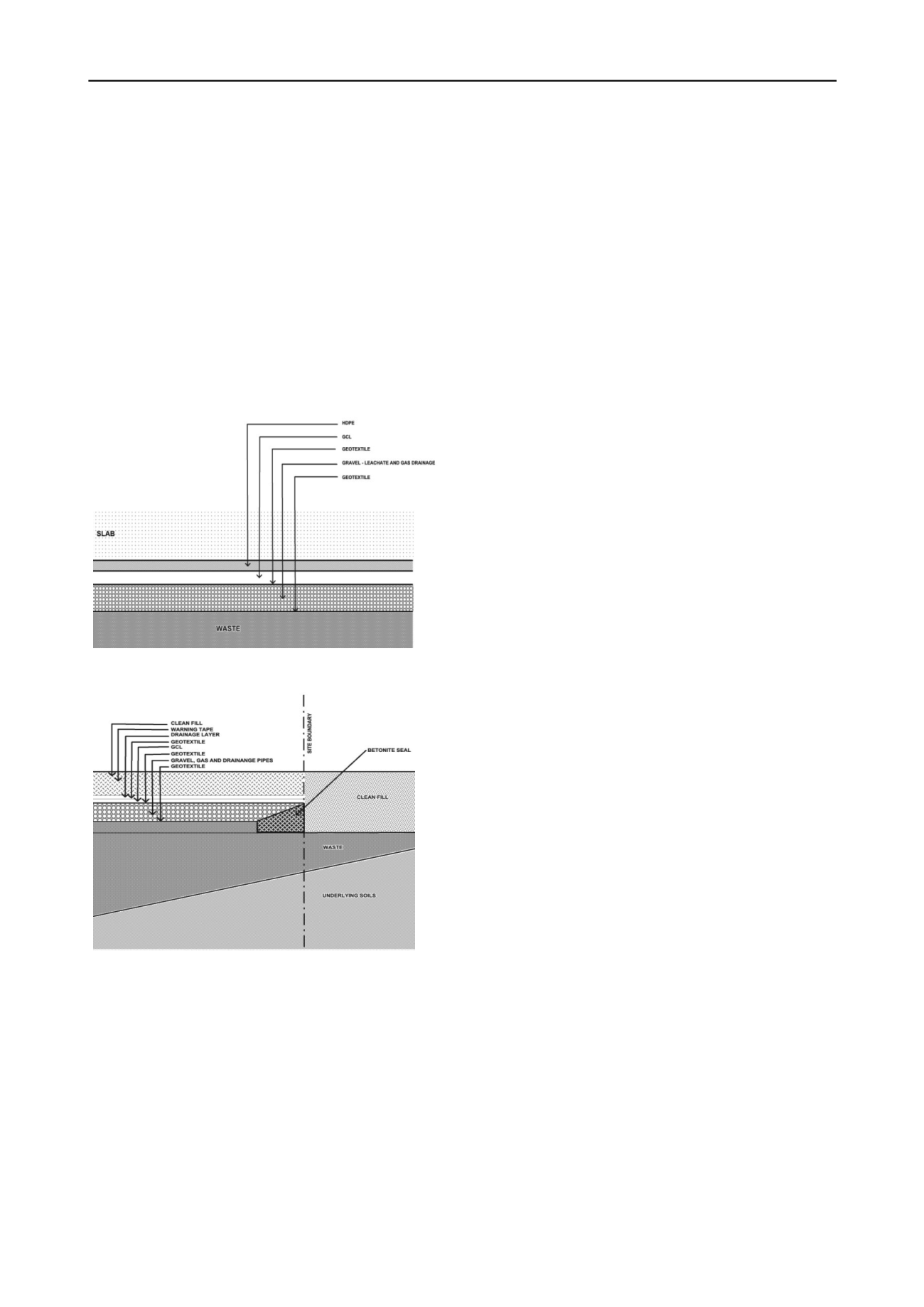

Figure 5: Preliminary design of cap for slab on ground

8 CONCLUSION

The use of dynamic compaction and construction of a landfill

gas drainage system together with innovative civil solutions will

allow the Fo Guang Shan Nan Tien Buddhist Order to develop

their site and create a teaching and cultural facility as part of the

existing Nan Tien Temple. Geotechnical and environmental

performance was monitored during site preparation works and

will be monitored during building construction.

9 ACKNOWLEDGEMENTS

The authors acknowledge the Fo Guang Shan Nan Tien

Buddhist Order and affiliates for assistance in the project and

their permission to use project specific data for this paper.

Figure 6: Preliminary design of cap at site boundary

Flaring of the gas, with ignition of the gas as it leaves the site

was considered, given its advantage of reducing the landfill gas

to a higher percentage of CO

2

and H

2

O vapour, however the

technical difficulties of operating the flare, the area required for

a flare plant and the cost of setting up and maintenance of the

plant, among others, far outweighed the advantages. The final

remedial option, venting to the atmosphere, was chosen for the

zero requirements for a specific treatment plant and operating

costs. As such the preliminary design consists of the placement

of turbine ventilator stacks around the site. Landfill gas

discharge will occur through stacks that will extend 1 m above

the proposed maximum building roof level across the site. To

monitor the landfill gas and minimise the potential of migration

off-site a series of monitoring wells will be installed.

10 REFERENCES

Standards Australia. 1993. Determination of the penetration resistance

of a soil – Standard Penetration Test.

Australian Standard AS 1289

6.3.1 – 1993.

Standards Australia. 1996. Guidelines on earthworks for commercial

and residential developments.

Australian Standard AS 3798 –

1997

.

Hausmann, M.R. 1990. Engineering Principals of Ground Modification.

McGraw Hill

.

Thom, M.J. 1998. The long term settlement behaviour of waste and its

effect on future development.

3

rd

National Hazardous and Solid

Waste Convention.

Department of Environment and Conservation NSW. 2006. Guidelines

for the NSW Site Auditor Scheme.

2

nd

Edition.