3232

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

Figure 1 shows part of their results. Seawater and fresh water

were tested with Portland cement and powdered blast furnace

slag (PBFS) as additives. When fresh water was used, cement

was more effective than PBFS in solidifying GBFS. But when

seawater was used, PBFS was more effective than cement.

Using seawater and PBFS was the most effective combination.

3

ISSUES REGARDING APPLYING THE GBFS

SOLIDIFICATION ACCELERATION METHOD IN THE

FIELD

There are several issues to consider when determining the most

appropriate mixture of GBFS and PBFS for accelerating GBFS

solidification: (1) the material can separate during construction,

(2) it may separate after construction because of water flow (3)

separation of the mixture is likely to affect how the GBFS

solidifies, (4) the flow of pore water can affect solidification,

and (5) GBFS may solidify differently when the pore water

changes from sea water to fresh water (Kikuchi et al. 2010).

In the present study, we examine issues (1) to (5). First, we

present experimental results regarding issues (2), (3), and (4).

We then explain a way to prevent issue (1), and finally consider

issue (5).

3.1

Possibility of material separation after construction

The physical properties of the GBFS used were

s

= 2.845

g/cm

3

,

dmin

= 1.175 g/cm

3

,

dmax

= 1.508 g/cm

3

, D

15

= 0.28 mm,

and D

50

= 0.38 mm. The physical properties of the PBFS used

were

s

= 2.890 g/cm

3

, with 5000 to 7000 cm

2

/g of specific

surface area. Artificial seawater was used as pore water.

The diameter of the PBFS was about 4

m assuming

spherical particles with no small holes. Thus, the GBFS and

PBFS may separate when the mixture is poured onto the seabed.

The ratio of D

15

for GBFS to D

85

for PBFS is more than 50.

This ratio is an indicator of the possibility of material separation

due to water flow through the material (Ishihara 2001).

We conducted experiments on the separation of the PBFS

from the mixture. In this series of experiments, specimens with

two layers were prepared. The lower layer of the specimen was

a mixture of GBFS with 20% PBFS by weight. The upper layer

was only GBFS. The relative density of each layer was 50%.

Water flowed from the bottom of the specimen with a

hydraulic gradient of from 10 to 40. This test was conducted in

a triaxial apparatus at a confining pressure of 50 kN/m

2

to

prevent boiling. The outlet velocity of the water at a hydraulic

gradient of 40 was 120 m/day. The total outlet water volume

from the specimen was 6 times the void volume of the specimen.

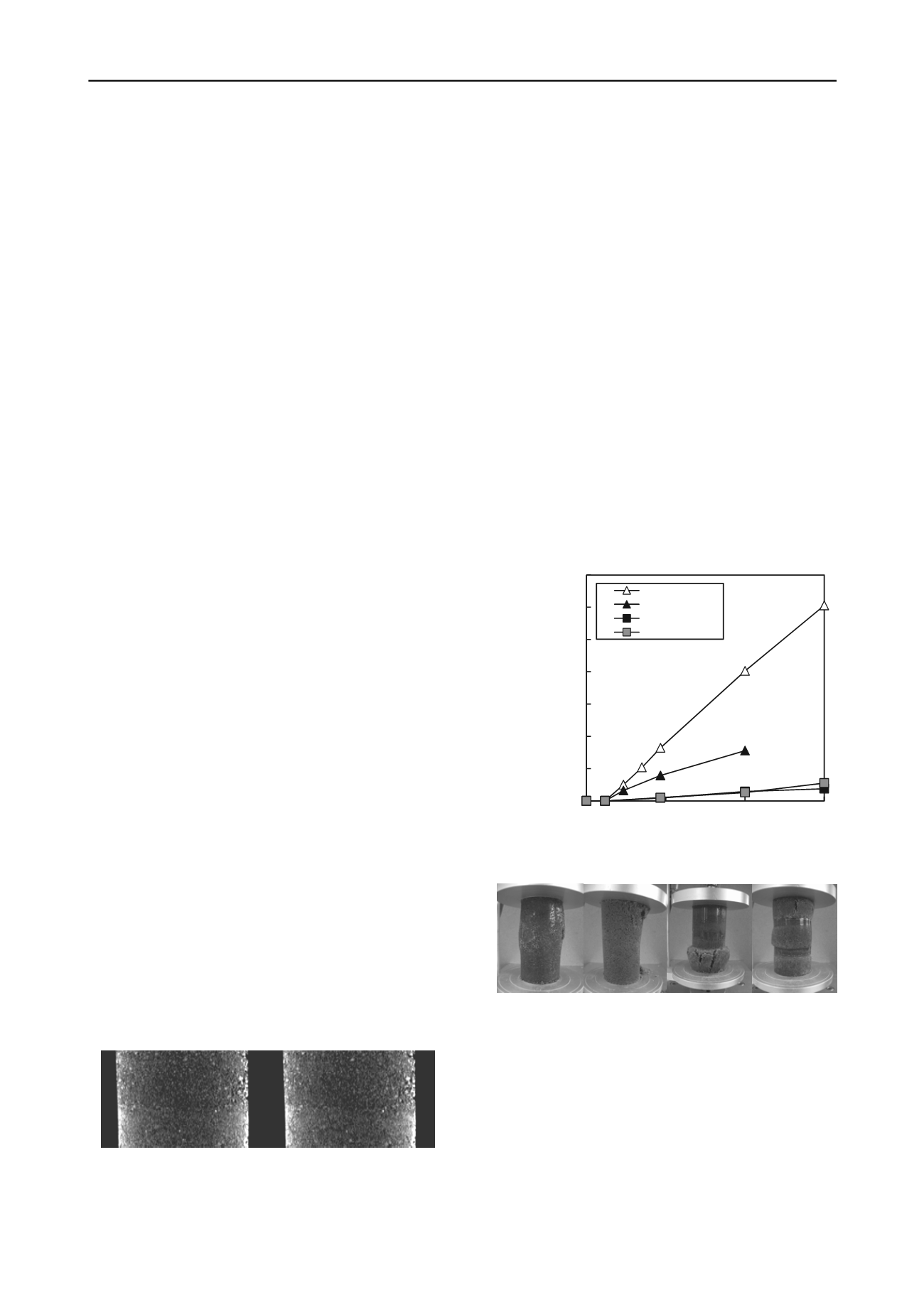

Figure 2 shows close-up X-ray CT images of the boundary

between the layers of the specimen, where the contrast reflects

the density of the material. Comparing the images before and

after water flow, small differences can be observed. This means

that although there may be a little separation when the peak

velocity of the water flow is 120 m/day, complete separation of

the material does not occur under these conditions.

In practice, the water flow velocity in GBFS used as backfill

for gravity quay walls is around several m/day. Thus, GBFS and

PBFS will never separate after construction.

Before water flow After water flow of 120m/day

Figure 2. Close-up X-ray CT images at mid-height of the specimen.

3.2

Solidification of GBFS after material separation

The effect of material separation on the solidification

characteristics of the material is examined in this section.

The GBFS and PBFS used here were the same as those used

in section 3.1. The relative densities of the specimens were 50%.

The pore water used was artificial sea water. In each specimen,

7.5% PBFS by weight was added to the GBFS. We tested four

experimental mixing regimes: (1) GBFS and PBFS were mixed

homogeneously (HMT), (2) PBFS was mixed with GBFS, then

artificial sea water was added to achieve a 10% water content

ratio and the mixture was cured in air for a week (prior

homogeneous mixing treatment or PHMT), (3) One PBFS layer

was sandwiched between two layers of GBFS, and (4) Two

PBFS layers were sandwiched between three GBFS layers.

Each specimen was saturated with artificial sea water and

sealed, then cured for a designated period at a constant

temperature of 20 degrees centigrade. Each specimen’s

unconfined compression strength was measured after the

designated curing period.

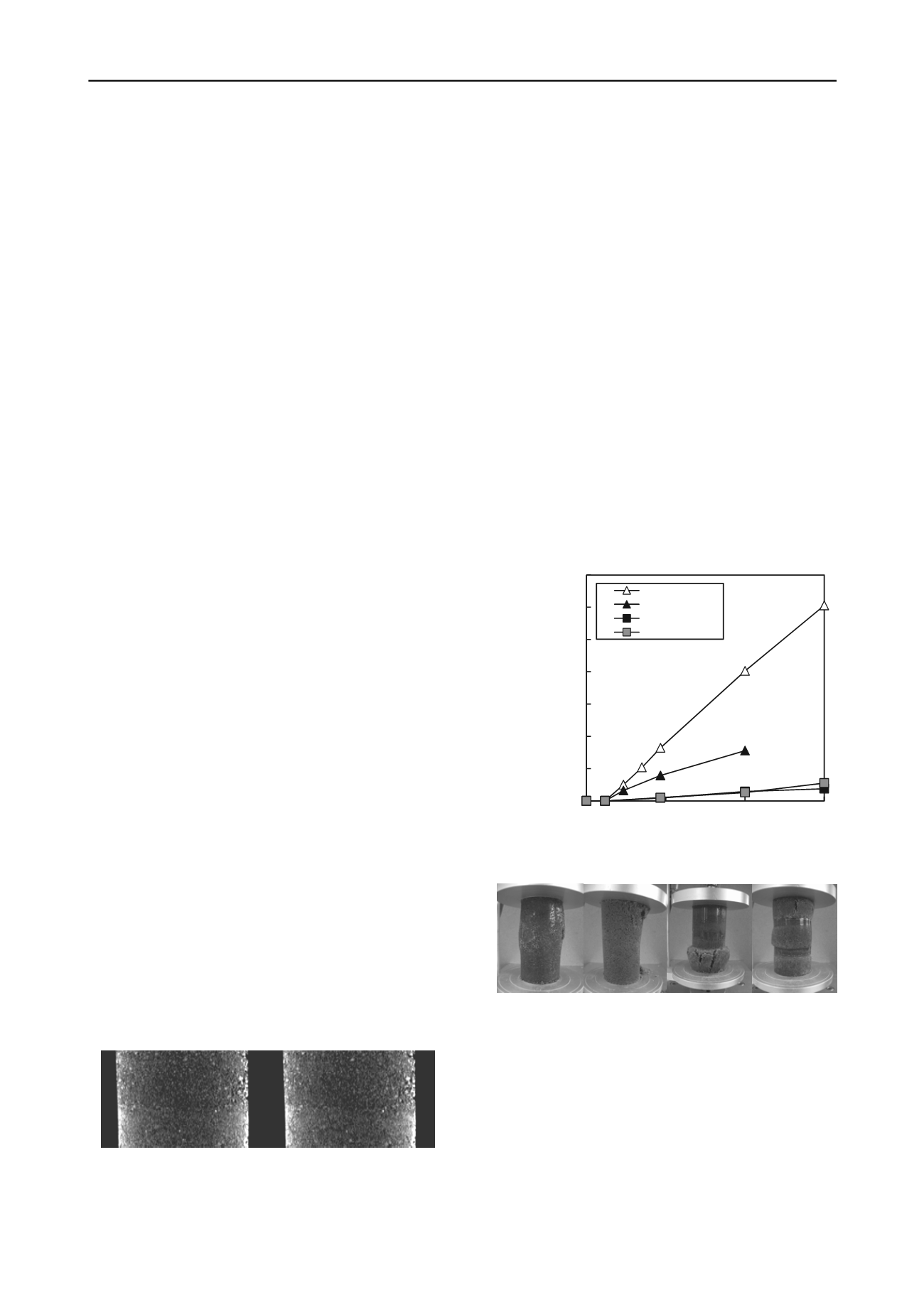

Figure 3 shows the relationship between the curing duration

and unconfined strength. The unconfined compression strengths

using HMT and PHMT exceeded 200 kN/m

2

after 14 days of

curing. These strengths increased as the curing time lengthened.

When the materials were separated, such as in cases (3) and (4),

the unconfined compression strengths were very low. Figure 4

shows examples of the failure states for each case.

0

500

1000

1500

2000

2500

3000

3500

0

30

60

Unconfined compression strength

q

u

(kN/m

2

)

Curing time (days)

90

HMT

PHMT

One layer

Two layers

Figure 3. Change of unconfined compression strength with curing time.

(a) HMT (b) PHMT (c) One layer (d) Two layers

Figure 4. Failure modes of specimens in each mixing regime

These results show the importance of thoroughly mixing the

GBFS and PBFS in accelerating the solidification of the GBFS.

3.3

Solidification of GBFS underground with flowing water

In previous research, movement of pore water has been shown

to prevent GBFS solidification (Kitayama 2003). In this section,

we examine how pore water flow effects GBFS solidification.

In this series of experiments, two water flow conditions and two

mixing conditions were tested.

We used the same GBFS and PBFS as in section 3.1, and the

HMT (1) and PHMT (2) mixing regimes from section 3.2.