3233

Technical Committee 307 /

Comité technique 307

In this series, sand boxes 30 cm wide, 30 cm long, and 50 cm

high were fitted with a bulb for supplying water, located 3 cm

from the bottom. Model ground 30 cm high was constructed of

a mixture of GBFS and PBFS with 50% relative density. This

was saturated with artificial sea water at the beginning of the

test. Tests were run under static water and flowing water

conditions. In the static water case, the pore water was never

changed during the experiment. In the flowing water case, a

volume of water equal to the volume of the voids in the ground

was supplied slowly from the bottom of the ground once every

three days. Curing continued for two months at a constant

temperature of 20 degrees centigrade. After curing, the bearing

strength distribution of the ground was measured using a soil

hardness meter, and was converted to unconfined compression

strengths.

The results show that the HMT-treated material subjected to

static water conditions was the strongest. The material that had

undergone HMT was weaker when cured in flowing water.

However, for the PHMT-treated material, the opposite was true.

With flowing water the PHMT material was stronger than the

HMT material, meaning that PHMT has a higher potential to

solidify GBFS than HMT under non-static water conditions.

3.4

Improving resistance to separation during construction

using PHMT

For this series of experiments, we used GBFS with the

following physical properties:

s

= 2.808 g/cm

3

,

dmin

= 1.199

g/cm

3

, and

dmax

= 1.562 g/cm

3

. The median particle diameter

(D

50

) was 0.74 mm. The physical properties of the PBFS were

s

= 2.890 g/cm

3

, with 5000 to 7000 cm

2

/g of specific surface

area. Artificial seawater was used as pore water.

As the GBFS and PBFS may separate when the mixture is

poured onto the seabed, PHMT was used to counter this

problem. With PHMT, some of the PBFS attaches to the GBFS

granules, making the mixture more resistant to separation and

decreasing the turbidity the mixture causes in water.

We mixed 10% seawater and 7.5% by weight of PBFS with

GBFS and cured the mixture for a designated period in air. We

measured the turbidity it caused after 0, 3, 7, 10, and 14 days of

curing. In each test, about 0.460 N of the PHMT mixture was

poured into 1000 ml of pure water and stirred well, then left to

sit for 30 min. A turbidity meter was used for measurements.

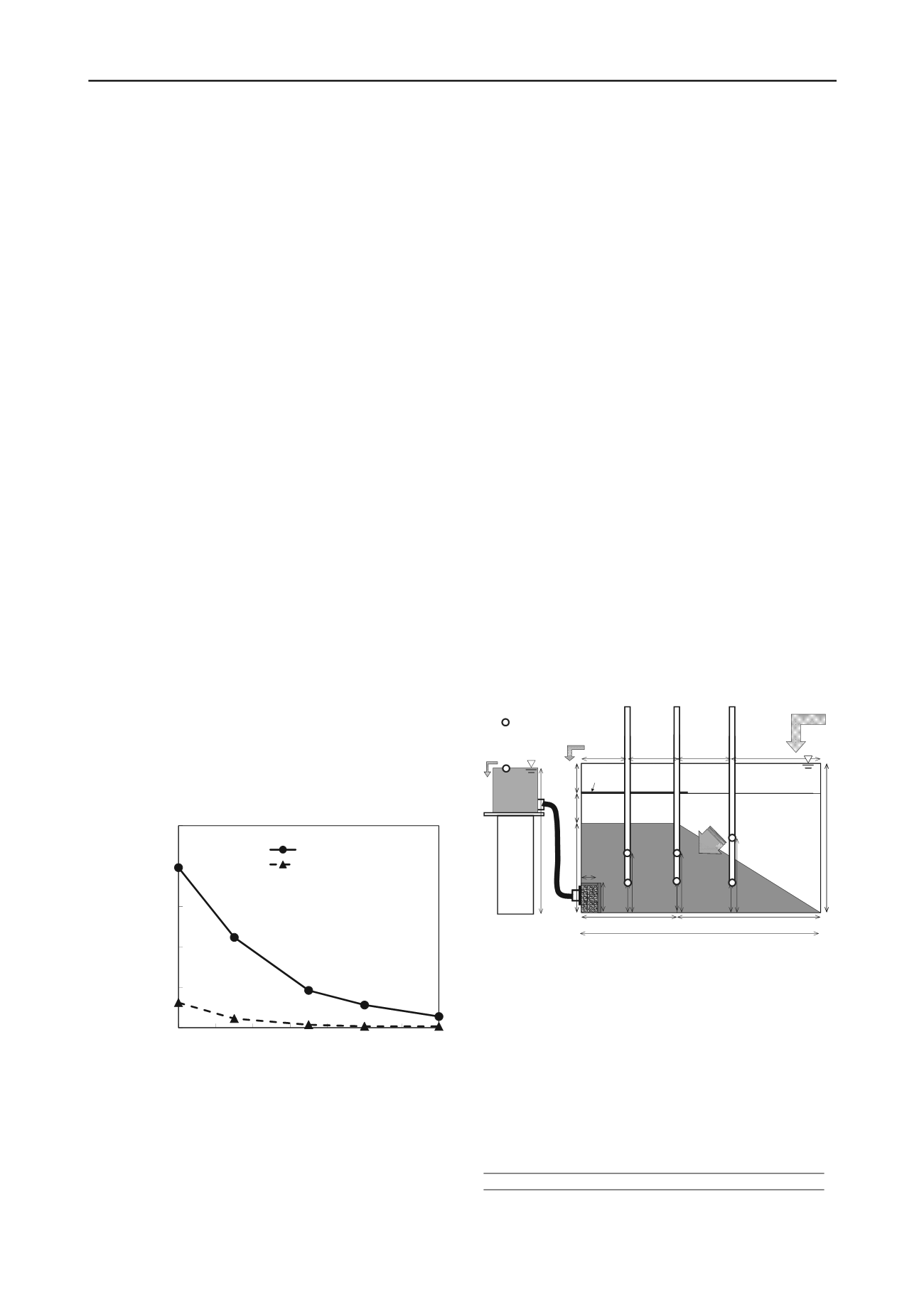

0

500

1000

1500

2000

2500

0 2 4 6 8 10 12 14

Suspended PBFS

concentration(mg/ℓ)

Curing time (days)

Just after mixing

30 min after mixing

Figure 5. Change in suspended PBFS concentration with curing time.

Figure 5 shows how the suspended material concentration

changed with curing time. The level just after mixing decreased

to one-fourth of its initial value after 7 days of curing. The

concentration 30 min after mixing became negligible after 7

days of curing.

A mixture of GBFS and PHMT is thus shown to be effective

in reducing the amount of material separation during

construction.

3.5

Effects of changing from sea water to fresh water on the

solidification of PHMT-treated GBFS

Here, we address issue (5) described above. The follow-up

survey about GBFS used as backfill noted in the introduction

revealed that the pore water in the GBFS layer changed

completely from seawater to fresh water over a period of 4

months (Kikuchi et al. 2005). This phenomenon occurs because

the mean ground water level is higher than the mean sea level

and rainfall supplies fresh water. Figure 1 shows that GBFS

mixed with PBFS in seawater solidified in a month. With this in

mind, we checked the effect of a pore water transition in a series

of laboratory experiments.

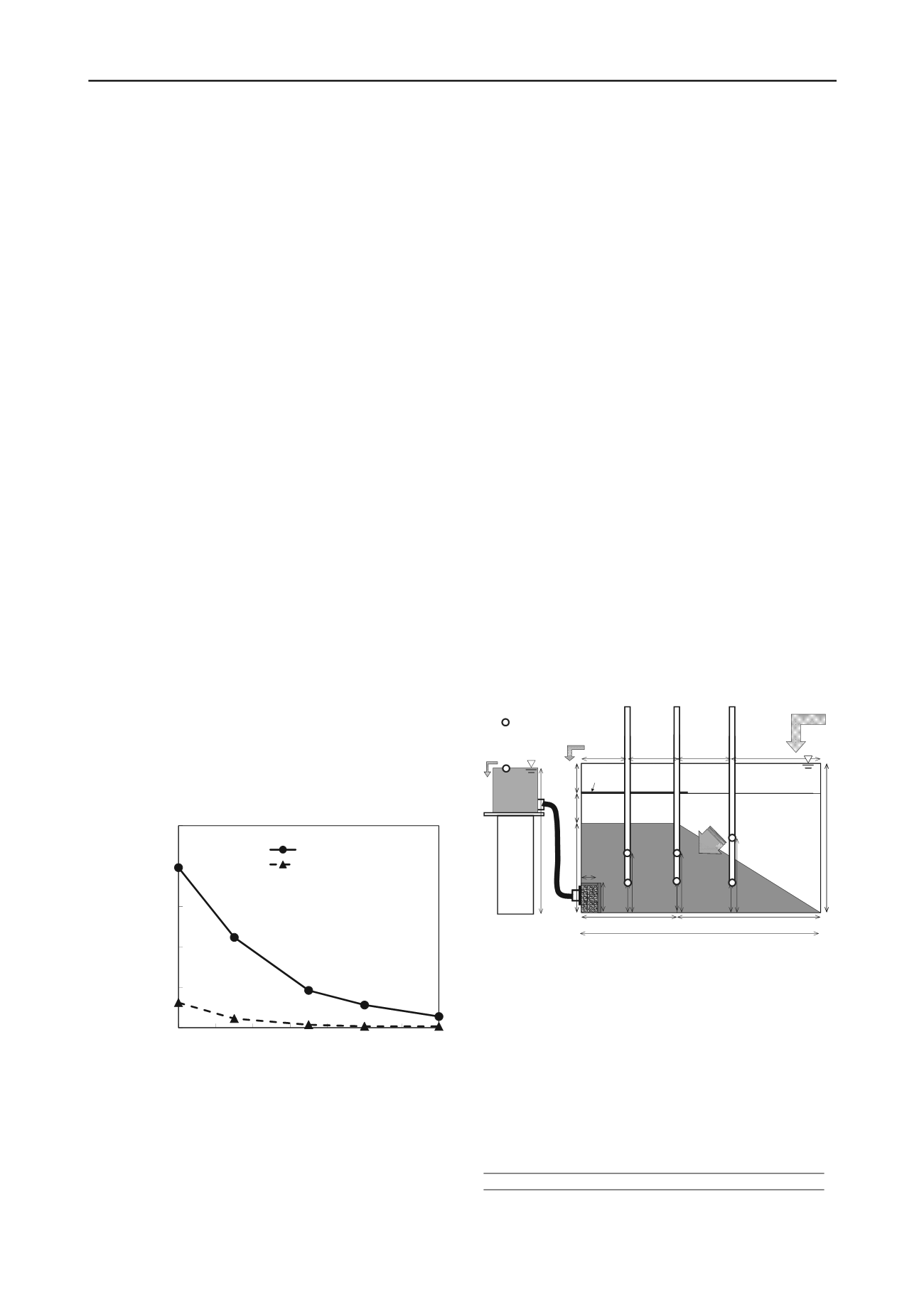

Figure 6 shows how the experiment was set up. The box

holding the sand was 800 mm long, 500 mm high, and 500 mm

wide. We used PHMT cured for 7 days, made following the

procedure described in section 3.2. The PHMT layer was made

when wet and was covered by the sand layer. We used silica

sand #4 (

s

= 2.644 g/cm

3

,

dmin

= 1.342 g/cm

3

, and

dmax

= 1.618

g/cm

3

). The relative densities of the PHMT and sand were 50%.

The water used to make the layers was artificial seawater,

except for case 4 (Table 2.), in which fresh water was used. The

shape of each layer is shown in Fig. 6. After making the model

ground, 6 standpipes were installed at the positions marked No.

1, No. 2, and No. 3 to collect pore water. Two pipes were

installed at each location to collect water from different depths.

The open circles in Fig. 6 show the points where pore water was

collected. Water was supplied as shown in the upper right part

of the figure at a rate of 6

l

per day. Effluent flowed from the

bottom of the apparatus as shown in the figure. Since the void

space in the model ground layer was about 84

l

, the hydraulic

retention time of the water in the apparatus was 14 days. Each

experiment was conducted at 20 degrees centigrade. As the

room was not perfectly temperature-controlled, its temperature

was somewhat affected by the outside temperature.

Influent

500

320

Effluent

800

480

150 170 180

300

100

200

200

100

100

250

300

100

100

Effluent

490

Silica sand

#4

No.1 No.2 No.3

:Measuring point

100

50

(Depth: 500)

Unit: mm

Impermeable liner

GBFS(PHMT)

Figure 6. Experimental setup

During the experiment, pore water was collected from each

point at designated times, and pH and salinity were measured.

After 8 weeks, the strength of the PHMT-treated GBFS was

measured with a Yamanaka soil hardness meter (Kikuchi et al.

2010). About 2000 strength measurements were made in each

case. The data collected were converted to unconfined

compression strengths using a relationship between strength and

hardness determined before the experiment.

Table 1 shows the types of water supplied in each case.

Table 1. Experiment conditions

Case

Condition

Case 1

Sea water supplied for 8 weeks

Case 2

Sea water supplied for 6 weeks, then pure water

supplied for 2 weeks