3228

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

To prepare SGM specimens, seawater taken from Hakodate

was used as the mixing water, blast furnace cement B as the

stabilizing agent, and air foam (with a density of 0.05g/cm

3

)

prepared with hydrolyzed animal protein using the pre-foaming

method as the foaming agent. These ingredients were then

mixed with each of the source soils that had been passed

through a sieve of 425

m and the resulting mixtures were put

into plastic molds with a 5cm diameter and a 10cm height. With

the top sealed by a plastic wrap, the mixtures were then cured in

the air until the prescribed curing ages were attained. Table 2

shows the flow values of the specimens after the water content,

w,

of the source soils used to prepare the SGM specimens for

this study was adjusted by sea water (hereafter “Adjusted Soil”)

and after the stabilizing agent and the air foam were mixed in.

The required wet density and the amount of stabilizing agent

added were respectively kept constant at

t

=1.1 g/cm

3

and 75

kg/m

3

, with the water content ratio of the Adjusted Soil at

285%, equivalent to 2.5

w

L

of Tokyo Bay A and B. While

Tokyo Bay A, B and Kobe had similar

w

L

values, the flow value

of Tokyo Bay B was slightly higher than those of the other two

after the stabilizing agent was added to the specimens. In

addition, the water content ratio of 285% was approximately

five times higher than the already low

w

L

of Kasaoka Clay,

causing its flow ability to rise. As a result, its flow value after

the stabilizing agent was added exceeded the size of the acrylic

plate (of 66 cm per side), which was used for the flow value

measurement.

The SGM was taken out of two cylinders per specimen on

each of the prescribed curing days to conduct the unconfined

compression test and the BE test. In the BE test, bender

elements were inserted in pairs at both vertical and horizontal

ends, and the shear wave velocity was measured in both vertical

and horizontal directions against the soil (

V

vh

,

V

hh

). From these

values and the wet density of the specimens,

t

, the elastic

shearing modulus (

G

vh

=

t

×

V

vh

2

,

G

hh

=

t

×

V

hh

2

) was obtained.

An internal observation of the SGM specimens was made using

an SEM on each of the prescribed curing days to examine the

correlation between the strength development and the

microscopic structure.

3 RESULTS AND DISCUSSIONS

3.1

Strength and Shear modules of the SGM specimens

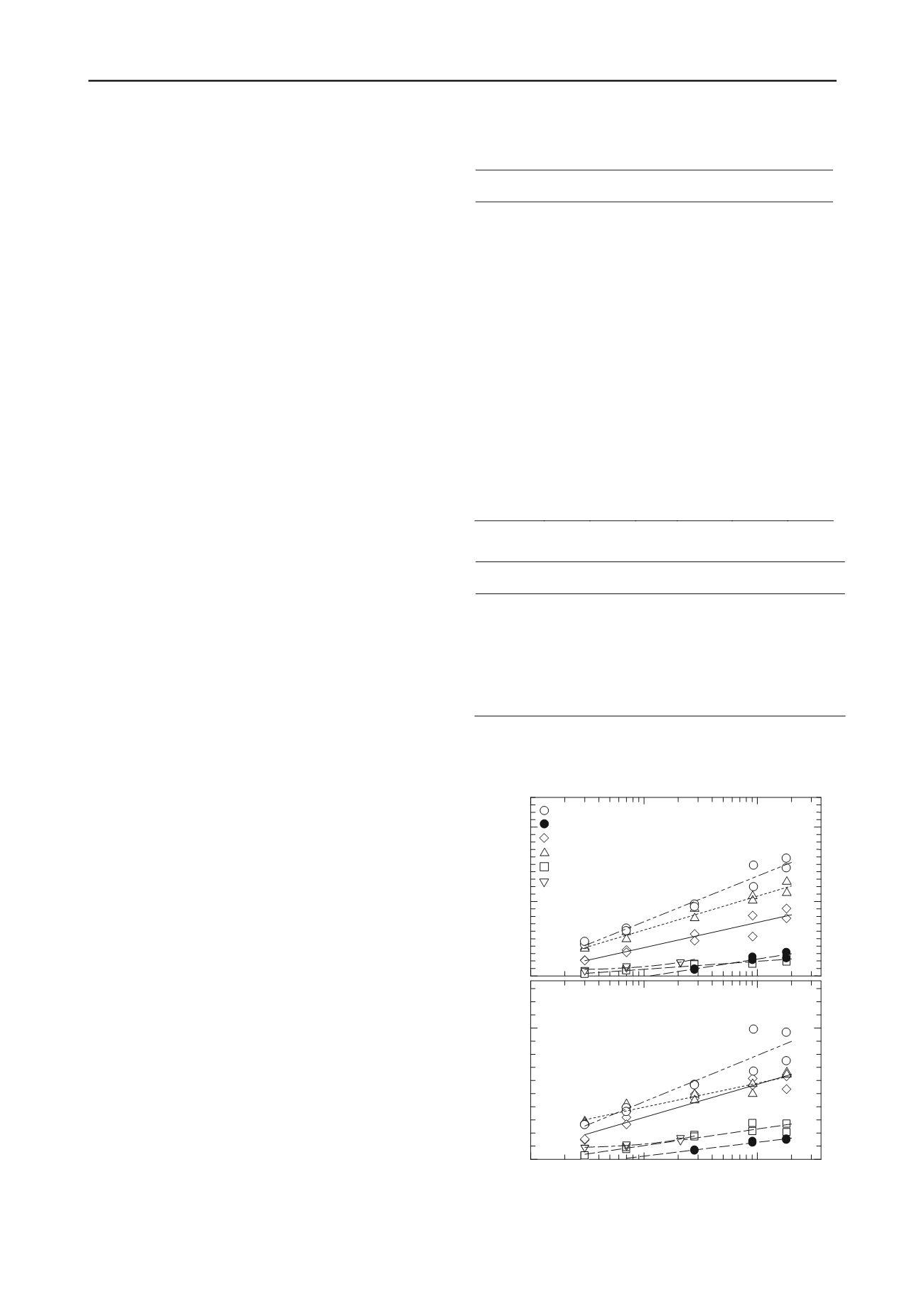

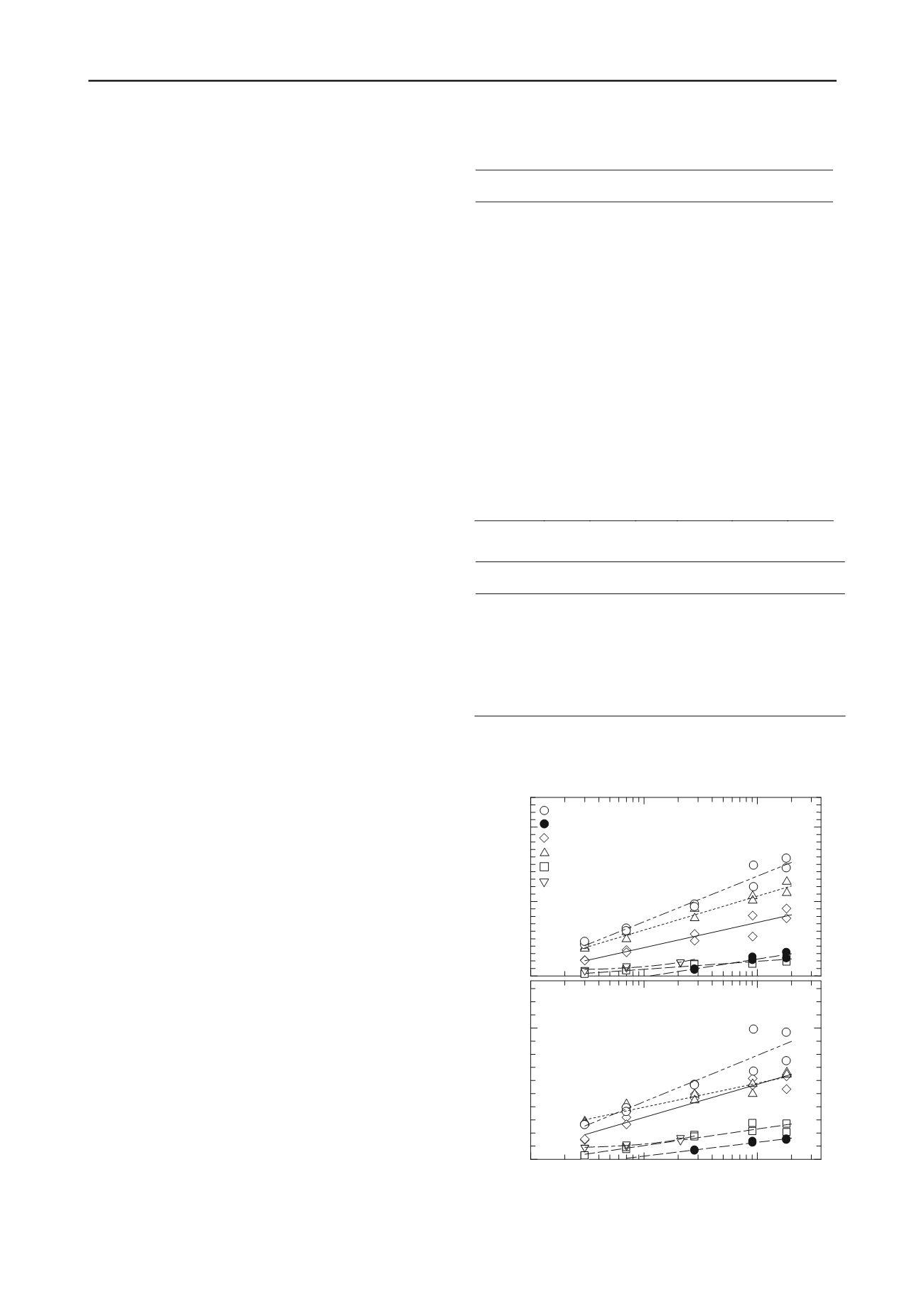

Figure 1 shows the changes to the

q

u

and

G

vh

levels of the

prepared specimens with the elapse of curing days. From the

results,

q

u

and

G

vh

of all specimens showed a linear increase in

the semi-log graph. However, a substantial degree of variability

was observed from one source soil to another in the soil strength

measured on the same curing day even though the mixing

conditions, such as the cement quantity per unit volume and the

w

of the Adjusted Soil were identical. In particular, among the

three types of dredged soil (Tokyo Bay A , Tokyo Bay B and

Kobe) that shared almost identical physical properties such as

w

L

, the

q

u

level of Tokyo Bay B was much lower than the other

two. It is suspected that the composition of the pore water was

suppressing the strength development of Tokyo Bay B, given

that its pH level was lower than those of the other two

specimens. On the other hands, the

w

L

levels of Okhotsk and

Kasaoka Clay were lower than those of the aforementioned

three types of dredged soil. While Okhotsk showed large

q

u

and

G

vh

values, comparable to those of Tokyo Bay A, Kasaoka Clay

had very low

q

u

and

G

vh

values, similar to those of Tokyo Bay

B. The factors causing the large

q

u

and

G

vh

values of Okhotsk

are suspected to be the large volume of silt in the soil. The small

q

u

and

G

vh

values of Kasaoka Clay are believed to be caused by

the material separation that occurred after the cement and air

foam were mixed in because of the high

w

ratio of the Adjusted

Soil of 285 %, about 5 times greater than its

w

L

. The decrease in

the strength of Kasaoka Clay is also likely to have resulted from

its clay mineral components since the pore water composition

Table 1. Sample preparation

samples

Tokyo

Bay A

Tokyo

Bay B

Kobe Okhotsk

Kasaoka

Clay

Kuni-

bond

s

(g/cm

3

)

2.62

2.70

2.64

2.56

2.71

2.70

w

L

(%)

114.7

112.4 108.2

85.6

55.4

133.1

L

i

(%)

10.4

11.5

9.7

7.2

8.2

7.8

pH

7.7

3.4

7.9

7.6

7.5

-

Grain size

distribution

(%)

Sand

2

8

0

6

7

6

Silt

27

21

31

47

33

65

Clay

(2~5

m)

38

32

33

23

16

16

Clay

(~2

m)

33

39

36

24

44

12

clay

mineral

Qtz

Pl

Ill

Chl

Sme

Qtz

Pl

Gp

Ill

Chl

Kln

Qtz

Pl

Ill

Chl

Sme

Qtz

Pl

Ill

Chl

Sme

Qtz

Pl

Ill

Sme

Kln

Qtz

Pl

Sme

Table 2. Water contents and flow values of the SGM specimens

samples

Tokyo

Bay A

Tokyo

Bay B

Kobe

Okhotsk

Kasaoka

Clay

Kuni-

bond

285

285

285

285

285

285

w

(%)

(2.5

w

L

) (2.5

w

L

) (2.6

w

L

) (3.3

w

L

)

(5.1

w

L

)

(2.1

w

L

)

Frow value

(cm)

Adjusted

soil

47.5

58.0

49.0

64.0

66.0 ~

57.0

SGM

19.0

27.5

21.0

36.0

66.0 ~

39.0

: 66.0 ~ shows 66.0 over

0

200

400

600

800

1000

1200

1 2

10 20

100 200

0

100

200

300

q

u

(KPa)

Curing period (day)

:

Tokyo Bay A (

w

L

=114.69%)

:

Tokyo Bay B (

w

L

=112.40%)

:

Okhotsk (

w

L

=85.61%)

:

Kobe (

w

L

=108.20%)

:

Kasaoka Clay (

w

L

=55.40%)

G

vh

(MPa)

:

Kuni−bond (

w

L

=133.1%)

Figure 1. Variation of

q

u

and

G

vh

with the curing periods