3234

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

Case 3

Pure water supplied for 8 weeks

Case 4

Pure water used for making the model ground and

Pure water supplied for 8 weeks

0.0

0.5

1.0

1.5

2.0

2.5

3.0

0

14

28

42

5

Salinity concentration(%)

Exposed time (day)

6

Case1

Case2

Case3

Case4

Figure 7. Change in salinity during the experiment (sampling location

No. 1-100).

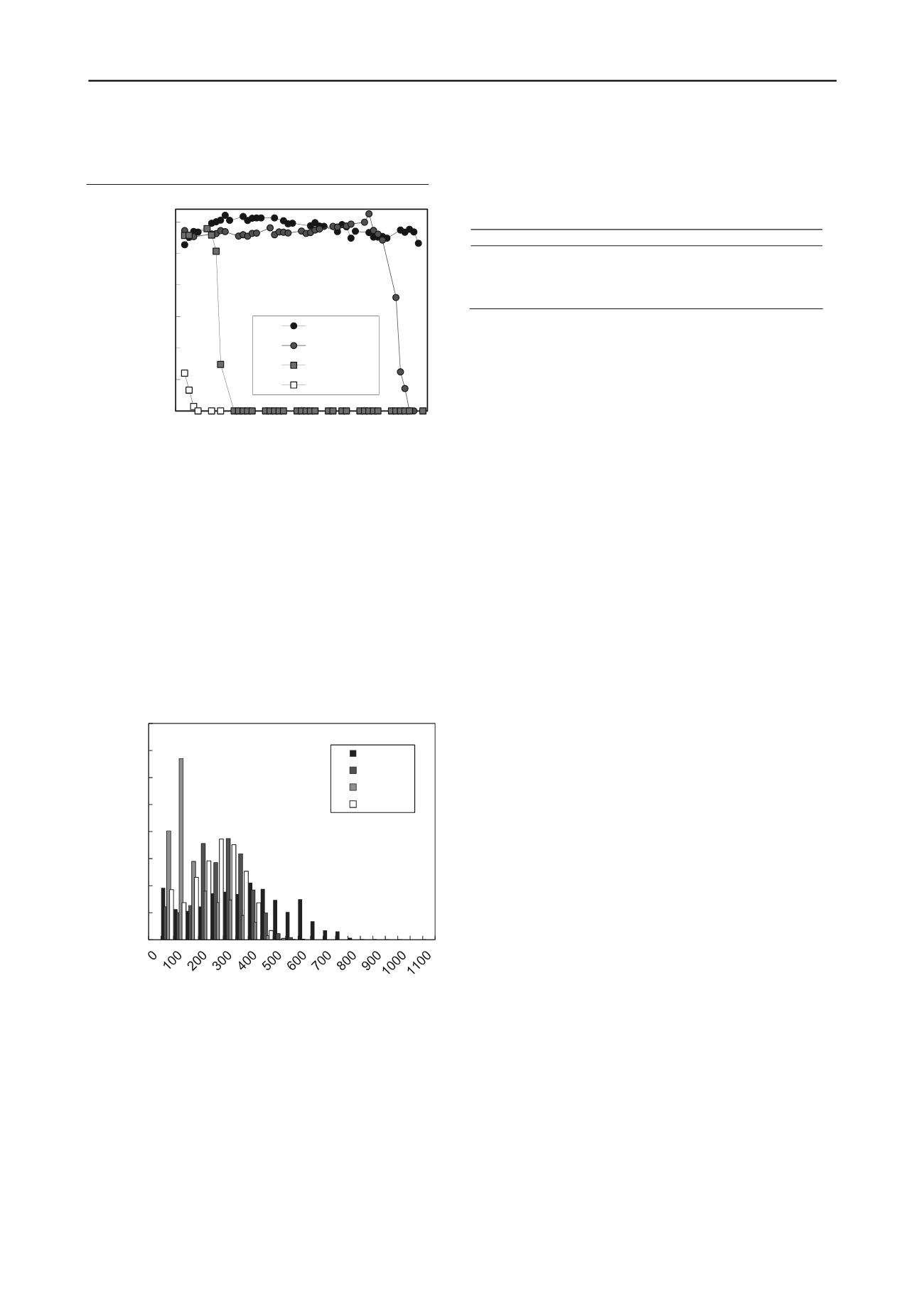

Figure 7 shows how the salinity changed during the

experiments in standpipe No. 1, 100 mm from the bottom of the

sand box. As shown in Table 1, fresh water was introduced

starting at 42 days of exposure time in case 2. The salinity

began to drop within about 1 week after the change and had

almost vanished within 3 or 4 days after that point.

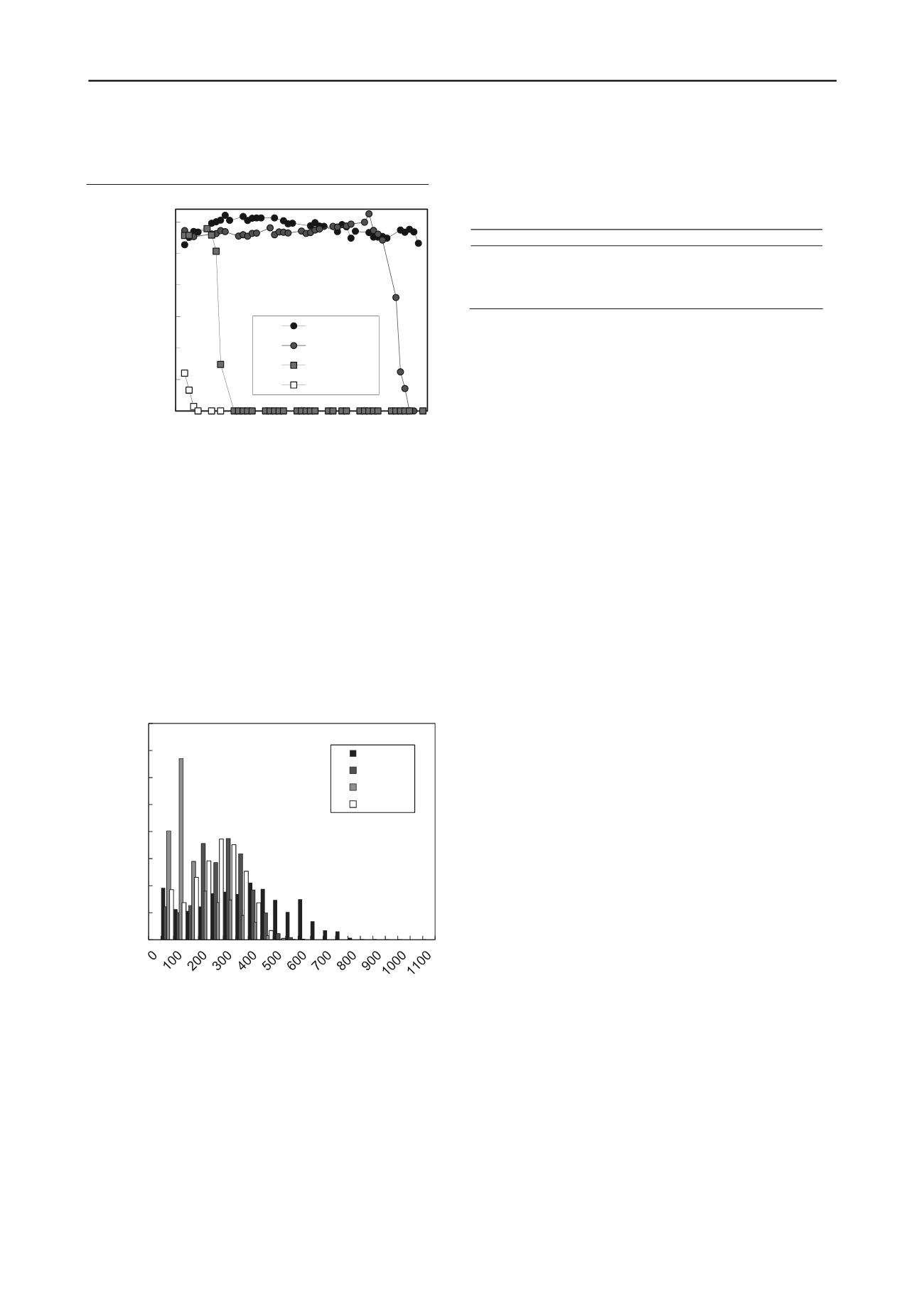

Figure 8 shows the converted unconfined compression

strength distribution in each case. Table 2 shows the maximum

and average strengths and the standard deviation for each case.

The highest strength was observed in case 1, followed by cases

2 and 4, which were similar, and the lowest was in case 3. From

these results, we see that about 2 months of curing time in

seawater is important for accelerated solidification.

0

5

10

15

20

25

30

35

40

Case1

Case2

Case3

Case4

Converted unconfined compression strength (kN/m

2

)

Frequency (%)

Figure 8. Distribution of converted unconfined compression strength.

An unconfined compression strength of more than 100

kN/m

2

is enough to prevent the liquefaction of sandy soil (Zen

et al. 1990). The fractions of data below this level were 15%,

11%, 54%, and 16% in cases 1, 2, 3, and 4, respectively. This

indicates that 80% of PHMT-treated GBFS cured in seawater

for more than 2 months is strong enough to protect against

liquefaction. This conclusion cannot be used to predict

solidification levels in the field, but the results show that this

technique can be used to accelerate the solidification of GBFS.

Finally, a series of permeability tests was conducted on

solidified GBFS specimens in triaxial cells. After the

permeability tests, the samples’ unconfined compression

strength was measured. These tests showed that the coefficient

of permeability decreased with increasing strength. However,

the coefficient of permeability was about 10

-4

cm/sec even when

the unconfined compression strength was about 1000 kN/m

2

,

indicating that the permeability of solidified PHMT-treated

GBFS is about the same as that of ordinary sand.

Table 2

.

Converted unconfined compression strength (kN/m

2

)

Case

Maximum

Average

Standard deviation

1

1060.2

331.4

189.4

2

550.8

244.9

107.9

3

500.7

130.5

99.5

4

493.9

213.4

102.9

4

CONCLUSION

The solidification of GBFS used in port structures can be

accelerated by adding PBFS. However, mixing PBFS with

GBFS presents some issues when used in actual construction

sites. To overcome these problems, we subjected the GBFS to

PHMT treatment. This paper demonstrates the superiority of

this process. PHMT reduces the amount of separation of the

GBFS/PBFS mixture and produces sufficient unconfined

compression strength after about 2 months of curing in

seawater, which occurs automatically when GBFS is used to

backfill quay walls. We conclude that PHMT-treated GBFS

solidifies at an accelerated rate and can be used to prevent

liquefaction.

5

REFERENCES

Coastal Development Institute of Technology. 1989. -

Manual for

granulated blast furnace slag used for port construction

, 71p. (in

Japanese)

Christian, G. D. 1986. -

Analytical Chemistry

, 4th Edition.

Ishihara, K. 2001.

Soil Mechanics

, p.83. (in Japanese)

Kikuchi, Y., Ikegami, M., & Yamazaki, H. 2005. Field investigation on

the solidification of granulated blast furnace slag used for backfill

of quay wall.

Journal of JSCE

No.799/III-72. 171-182.

Kikuchi, Y., Oka, S., & Mizutani, T. 2010. Examining field application

of solidification acceleration method of granulated blast furnace

slag,

Report of PARI

, 49(2). 21-46.

Kikuchi, Y., Nakashima, K., & Mizutani, T. 2007. Acceleration of

Solidification of Granulated Blast Furnace Slag.

13th Asian

Regional Conference

. CD-ROM.

Kikuchi, Y., Nakashima, K., Oka, S., & Mizutani, T. 2011.

Solidification acceleration and solidified shear strength evaluation

of granulated blast furnace slag.

Journal of JSCE

C 67(1). 145-159.

Kikuchi, Y., Nakashima, K., Kimura, J., and Mizutani, T. 2006. -

Solidification of granulated blast furnace slag used for port

construction,

Report of PARI

, 45(2), 105-133. (in Japanese)

Kitayama, N. 2003.

Studies on application of granulated blast furnace

slag to SCP method with low sand replacement ratio

. PhD thesis,

Yamaguchi University, 155p.

Nippon Slag Association. 1980.-

Granulated blast furnace slag -

Technical report on earth work material -

, 63-64. (in Japanese)

Nishi, M., Sato, Y. and Nanbu, M. 1982. - Strength characteristics of

granulated blast furnace slag as a land reclamation material,

Tsuchi-

to-Kiso

, JGS, 30(12), 41-48.

Zen, K., Yamazaki, H., & Sato, Y. 1990. Strength and deformation

characteristics of cement treated sand by premixing method.

Report

of PHRI

, 29(2). 85-118.