3236

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

4 SITE INVESTIGATION AND RESULTS

4.1

Geotechnical

Investigations to establish a geotechnical model of the site

included 103 test pits to depths of up to 5 m, 14 cored boreholes

to depths of up to 12 m and the installation of 8 standpipe

piezometers. In summary, the natural geological profile of the

site comprised topsoil over residual clays with latite and

sandstone bedrock (generally of medium to high strength)

below depths of 1 – 1.5 m. The profile of the landfill included a

coal washery rejects (CWR) and clay capping layer some 0.5 –

3.5 m in thickness (but generally less than 1 m) with the depth

of the waste in the order of 4 – 12 m.

The landfill waste was interbedded with CWR and clays, as

was expected given the conventional operation of a putrescible

waste facility. The density of the landfill was generally loose

with some denser sections as reflected by standard penetration

test “N” values in the range 2 – 30. Perched water tables were

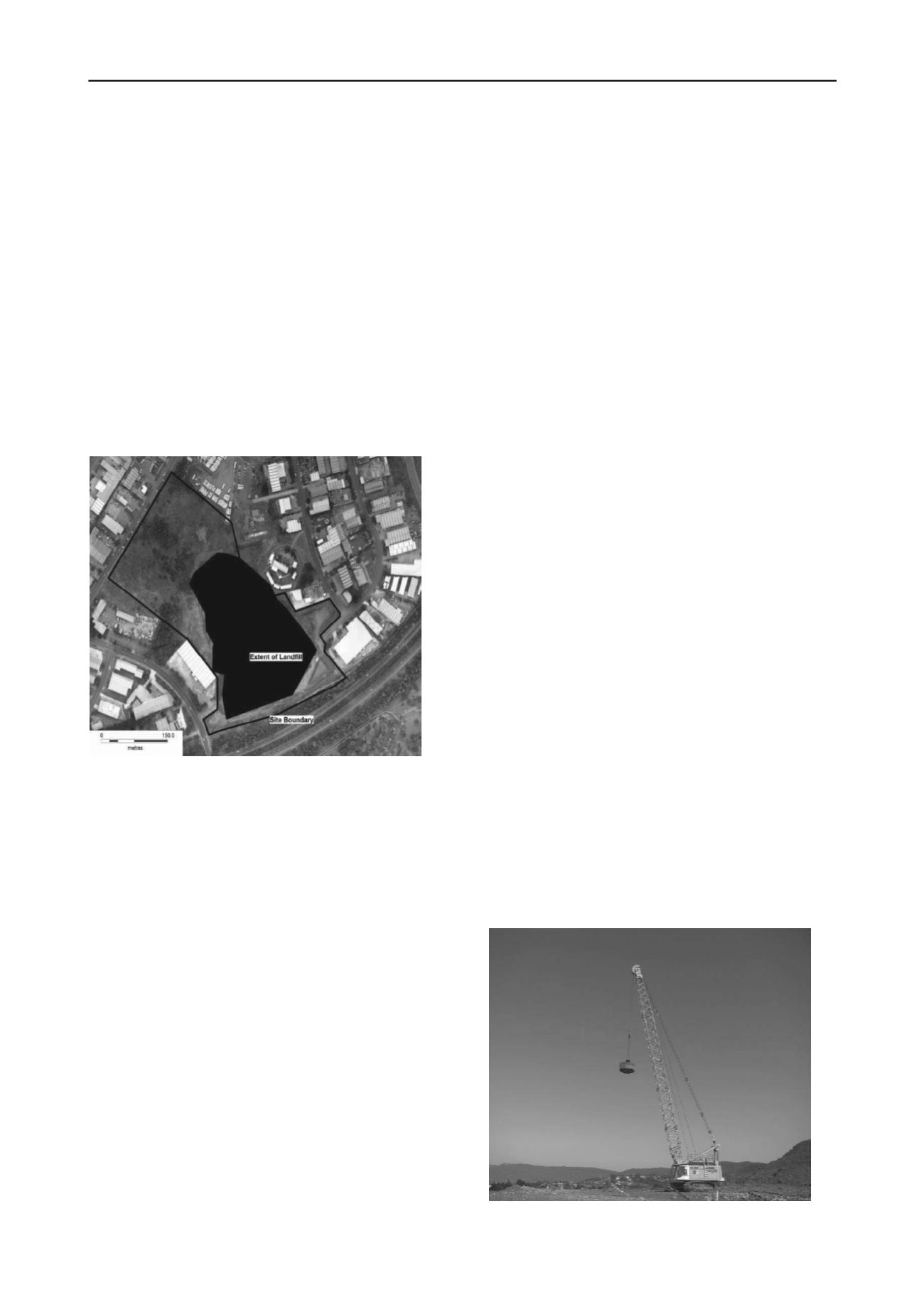

also present. The extent of the landfill is shown in Figure 1.

Figure 1. Extent of landfill.

4.2

Environmental (soil, water, air, noise)

180 test locations were investigated across the site, most of

which were in the landfill footprint. Contaminant

concentrations were compared to the NSW DECC (2006)

Health based Investigation levels. Within the soils, elevated

levels of manganese and hydrocarbon (C10 – C36) were

recorded. Testing of groundwater indicated elevated levels of

iron, manganese, ammonia, nitrate and total phosphorus, typical

of levels and contaminants found in landfill leachate. Methane,

hydrogen sulphate and carbon dioxide were recorded in the gas

monitoring wells with the methane levels within either the

“explosive” range or exceeding the “explosive limits” and in a

range that may cause asphyxiation.

In the areas outside the landfill footprint, no environmental

concerns were recorded apart from random dumping of

uncontrolled fill which was managed by conventional

construction practices.

5 GROUND CONSOLIDATION WORKS

Site preparation was completed in March 2011 and included

construction of a temporary leachate collection system,

reshaping and benching of most of the site, dynamically

compacting the landfill and undertaking of controlled

earthworks to achieve design levels. Monitoring of air quality,

noise, vibration levels and leachate was ongoing during the

works.

5.1

Civil Design and Leachate Control

During initial site works, the expectation was that a relatively

significant quantity of leachate would discharge from the

landfill cell which would reduce after dynamic compaction.

The reduced quantities were expected to be treated and

managed long term by a membrane bio-reactor (prior to

discharge off site or re-use on site). As the bio-reactor could

not be sized to cater for the high loads during site preparation

works, a 2ML leachate pond was constructed downslope of the

landfill cell. Leachate was fed into the pond via a 2 m

groundwater cut-off trench installed around the toe and flanks

of the landfill cell. Once in the pond, leachate was then pumped

through a treatment system consisting of pumps, sand filters,

activated carbon filters and an automatic sampler prior to

discharge into the sewer system via a Trade Waste Agreement

with Sydney Water.

The leachate pond was designed to not only suit its purpose

during dynamic compaction and site preparation (i.e. as a

leachate pond), but to also double as an on-site detention (OSD)

pond during the life of the Institute. This OSD pond assists

with long-term management of stormwater on the site. The

HDPE liner installed in the leachate pond during dynamic

compaction was removed and the pond readily transformed for

the OSD purpose. This saved having to build two very similar

structures twice.

5.2

Dynamic Compaction

In order to improve the density of the landfill (and thus to

improve longer term performance by limiting primary

compression and secondary consolidation following progressive

waste decomposition), dynamic compaction was selected as the

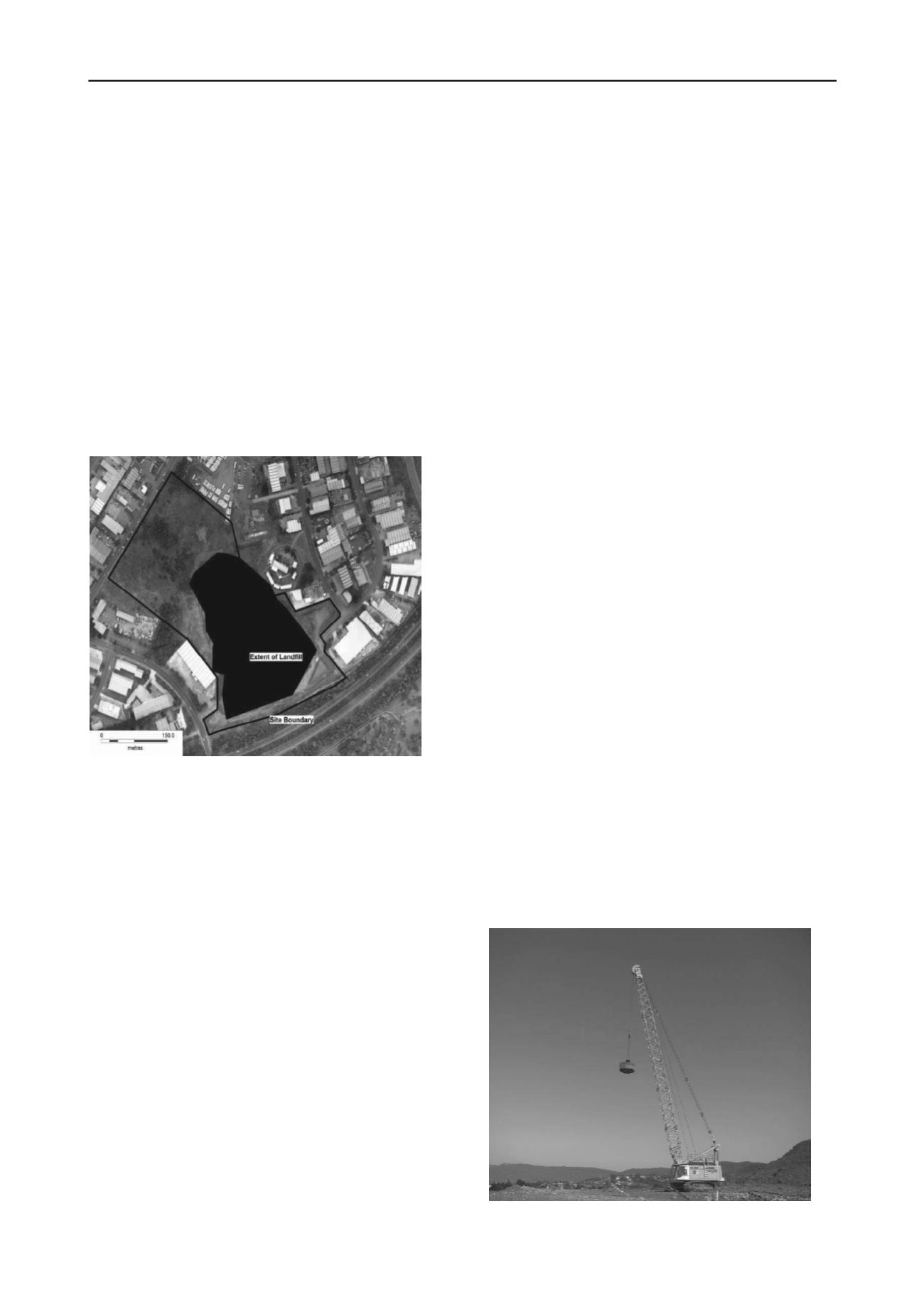

appropriate method. The equipment (shown in Figure 2)

included a 120 tonne crawler crane dropping a 25 tonne pounder

from a height of (nominally) 20 m. Compaction was carried out

in two phases. Following placement of a coarse “compaction

layer” to provide stability for the crane, the primary phase

comprised multiple drops of the concrete pounder (typically 3 –

4) on a 6 m x 6 m grid with the craters backfilled as the

compaction proceeded. The final (or ironing) phase was carried

out using a pounder of similar mass but a larger footprint (5 –

9 m2) with a drop height adjusted to the pounder size and

compression achieved.

Using the methods of Hausmann (1990), an assessment was

made of the degree of ground improvement with surface

settlements of generally 1 – 2 m expected in the areas underlain

by the deeper landfill. The survey results following completion

of dynamic compaction and were predominantly within the

range 0.5 – 1.5 m, in line with expectations and generally 10 –

12% of overall landfill depth.

Figure 2. Dynamic Compaction Equipment.