3245

Technical Committee 307 /

Comité technique 307

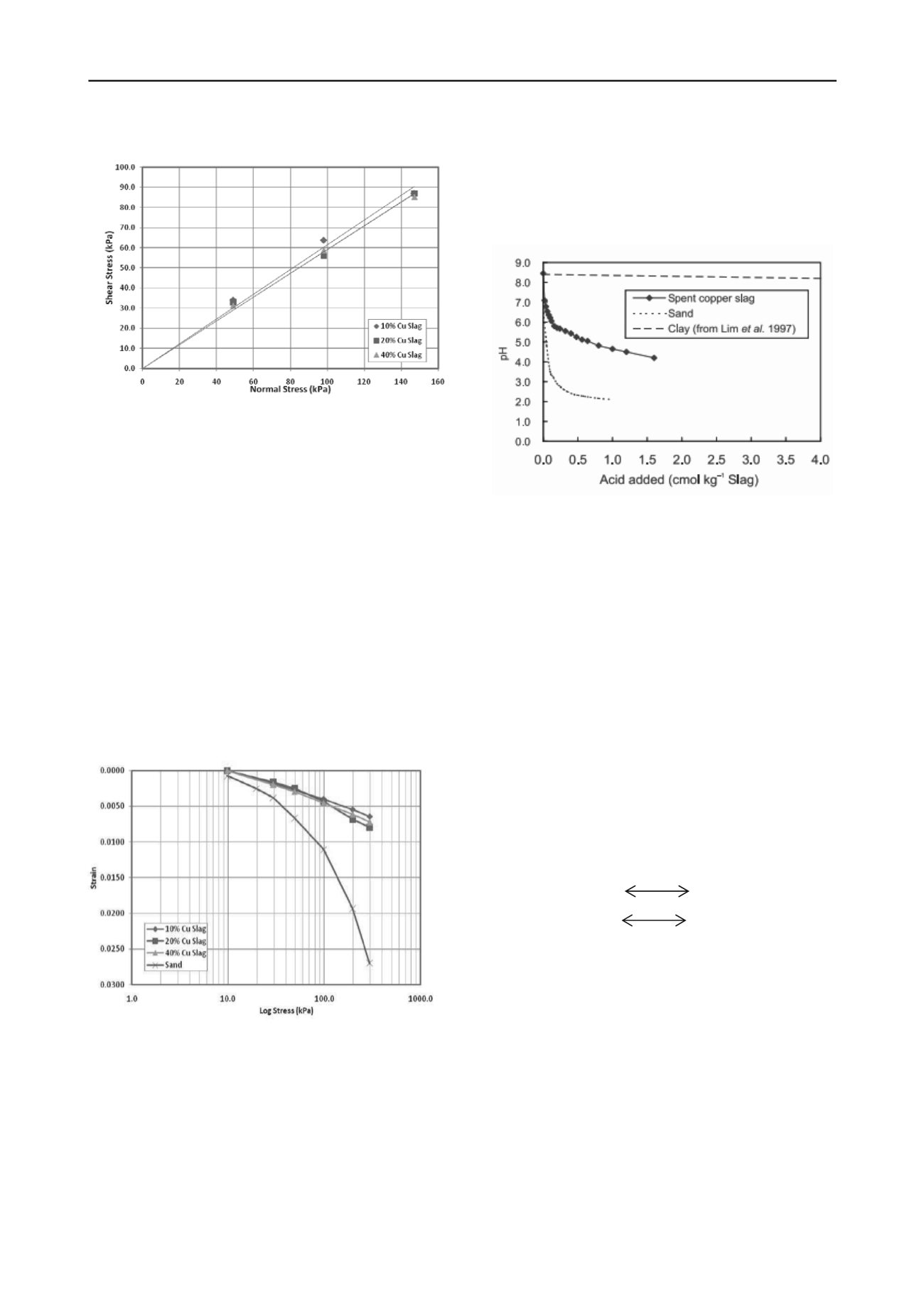

4 STIFFNESS

The most significant effect of the addition of waste copper slag

to sand was observed in confined compression tests. Dry

specimens were tested in a consolidation apparatus to ascertain

settlement and stiffness properties of the material. Standard

consolidation tests with fully saturated samples were not

warranted as the material had a very high hydraulic conductivity

and consolidation would have occurred at a rapid rate. Strains

were measured for different stress changes by applying loads on

to the sample.

Figure 5

shows the results in the form of a typical

strain vs log stress plot. There is clear distinction between the

behavior of the sand and the copper-sand mixes. The addition of

just 10% of waste copper slag drastically increases the stiffness

of the material. All three curves for copper-sand mixes are

tightly grouped which suggest that increasing the proportion of

copper slag more than 10% does not have any further effect.

Figure 5: Compression Characteristics of Copper-Sand Mixes

figure 6: Compression characteristics of copper-sand mixes

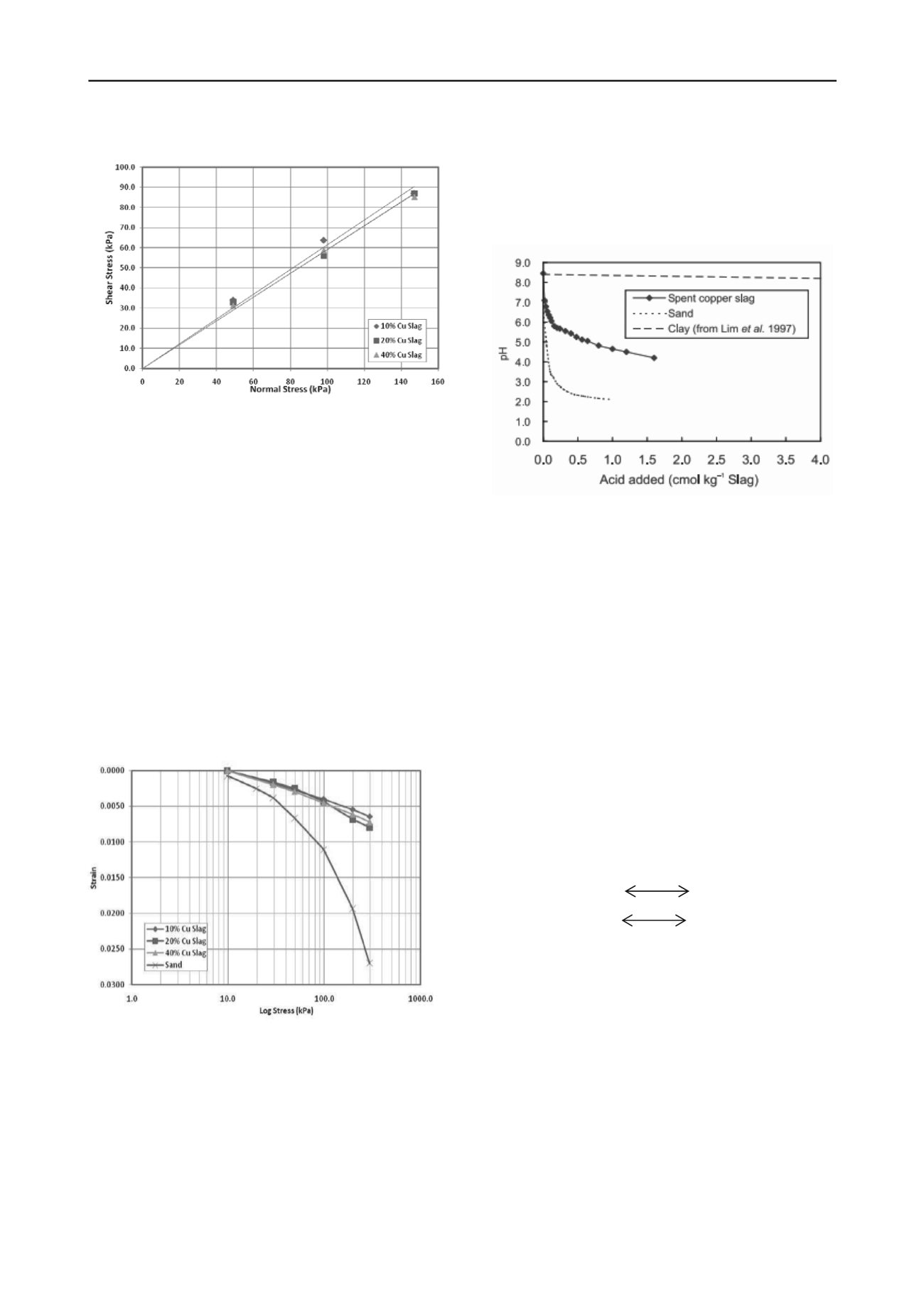

5 GEOCHEMICAL CHARACTERISTICS OF USED THE

COPPER SLAG

Chemical properties of the used copper slag as a percentage of

total weight are Iron Oxide-Fe

2

O

3

55%, Silica-SiO

2

35%,

Aluminium Oxide-Al

2

O

3

3.01%, Calcium Oxide-CaO 0. 20%,

Magnesium Oxide-MgO 0. 90%, Copper-Cu 0.42%, Titanium

Di-oxide 0.60%, and Potassium Oxide 1. 02% (Hammarstrom et

al.1999). The geochemical characteristic of used copper slag

can be analyzed for its element content, pH, acid neutralization

capacity (ANC), redox potential (Eh), and electrical

conductivity (EC). According to the previous research done by

Lim et al. (1997), it is clear that the pH of leachate generated

from the used copper slag is around 8.4. This pH value is within

the common pH range for soils and groundwater. Figure 6

shows the variation of pH- acid titration curves for used copper

slag and natural soils (Moyer et al. 2000).

Figure 7: pH- acid titration curves for used copper slag and natural soils

(After Moyer et al. 2000)

Figure 7

clearly illustrates that the used copper slag has a

rather low ANC in comparison with the clay. Sand has

practically negligible ANC. The low ANC value indicates that

the spent copper slag is not resistant to acid attack. The

concentration of Pb, Cd, Cr, Ba, As, Ag, Se, Cu, Zn, Ni and Hg

in the used copper slag leachate are fairly low. The leachabilitie

of Cu and Zn metals are much higher when compare with Cd,

Pb, Cr and Ni. The impact of the heavy metals leachability

would be nullified by dilution process under larger water: slag

ratio. Another important property of the used copper slag is the

Eh value. The initial Eh value for the used copper slag is 171

mV at a solid: water ratio of 1:1. The Eh would continue to

decrease rapidly days after placing the copper slag. Due to the

presence of sulphide minerals, the used copper slag can be

oxidized under oxic condition and release H

+

into the pore

water. As a result, there is a marginal drop in pH. The reduction

can be expressed by the following reactions such as reactions of

pyrite and ferrous. The amount of H

+

generated from this

reaction is very low and do not have enough reaction power to

make significant changes in double layer of clay minerals.

Pyrite oxidation:

4FeS

2

+ 14O

2

+ 4H

2

O 4Fe

2+

+ 8H

+

+ 8SO

4

2-

Fe (11) oxidation:

4FeSO

4

+ O

2

+ 10H

2

O 4Fe (OH)

3

+ 8H

+

+ 4SO

4

2-

The variation in pH due to present of heavy metals can be

affected to the groundwater pollution scenario. According to the

previous research done on used copper slag, it is clear that the

effect of groundwater pollution scenario is very unlikely to

occur (Lim et al. 1997).

Figure 4: Mohr-Coulomb Failure Envelopes for Copper-Sand Mixes

6 CONCLUSIONS

Results have show that the hydraulic conductivity of the

tested sand was hardly affected by the addition of waste copper

slag due to the void ratio and the hydraulic conductivity of the

waste copper slag itself being very similar to that of the sand.

Investigation of the geochemical characteristics of the used

copper slag alleviates the concern of possible groundwater

pollution by its use. Therefore, it can be concluded that used

copper slag can safely and effectively be used as a replacement

for sand in vertical drains.

The shear strength of properties of the tested sand-copper

slag mix was found to be very insensitive to the amount of