3253

Technical Committee 307 /

Comité technique 307

3 CONSTRUCTION PROCEDURE AND

INSTRUMENTATION.

The walls construction process was conducted using the moving

formwork technique, which is a common method for the

construction of wrapped-faced walls in the field. In order to

reduce the side wall friction, the whole internal walls of the test

facility were covered with three polypropylene sheets

interspersed with lubrication (liquid silicone).

Three walls sections were named according to their cardinal

orientation as West, Central and East. This configuration allows

for the instrumented portion of the wall (Central section) to

approach a plane-strain condition, free from side wall effects, as

far as practical. This procedure has been adopted at Royal

Military College of Canada (RMC) in a successful long-

standing program on construction of full-scale reinforced walls

(Santos et al. 2010).

The construction procedure consisted of placing the backfill

material and compacting it in 200mm lifts. In order to provide a

light compaction and a satisfactory surface leveling, a manual

compaction roll was used. Near to the face, a hand tamping

cylinder was used to minimize the effects of the compaction on

the facing displacements. The total construction time was 29

days. Figure 4 and Table 3 present RCDW reinforced walls

construction history and their main characteristics.

Figure 4. RCDW reinforced walls construction history (Santos et al.

2010).

Table 3. Main walls characteristics.

Value

Characteristic

Wall #1

Wall #2

Geosynthetics

Geogrid Geotextile

Height (m)

3.60

Facing batter (°)

13

Reinforcement spacing (m)

0.60

Reinforcement length (m)

2.52

Approximately 400 instruments were installed in the two

walls in order to record the following:

a. strain in reinforcement layers (strain gauges and wire-

line extensometers installed in wall #1 and wall #2,

respectively);

b. wall face displacements;

c. vertical earth pressure at the base of the RCDW (earth

pressure cells - EPC);

d. horizontal earth pressure within the RCDW mass

(EPC);

e. settlements along the surface of the RCDW mass

(superficial marks);

f.

horizontal displacement of the foundation soil

(inclinometer).

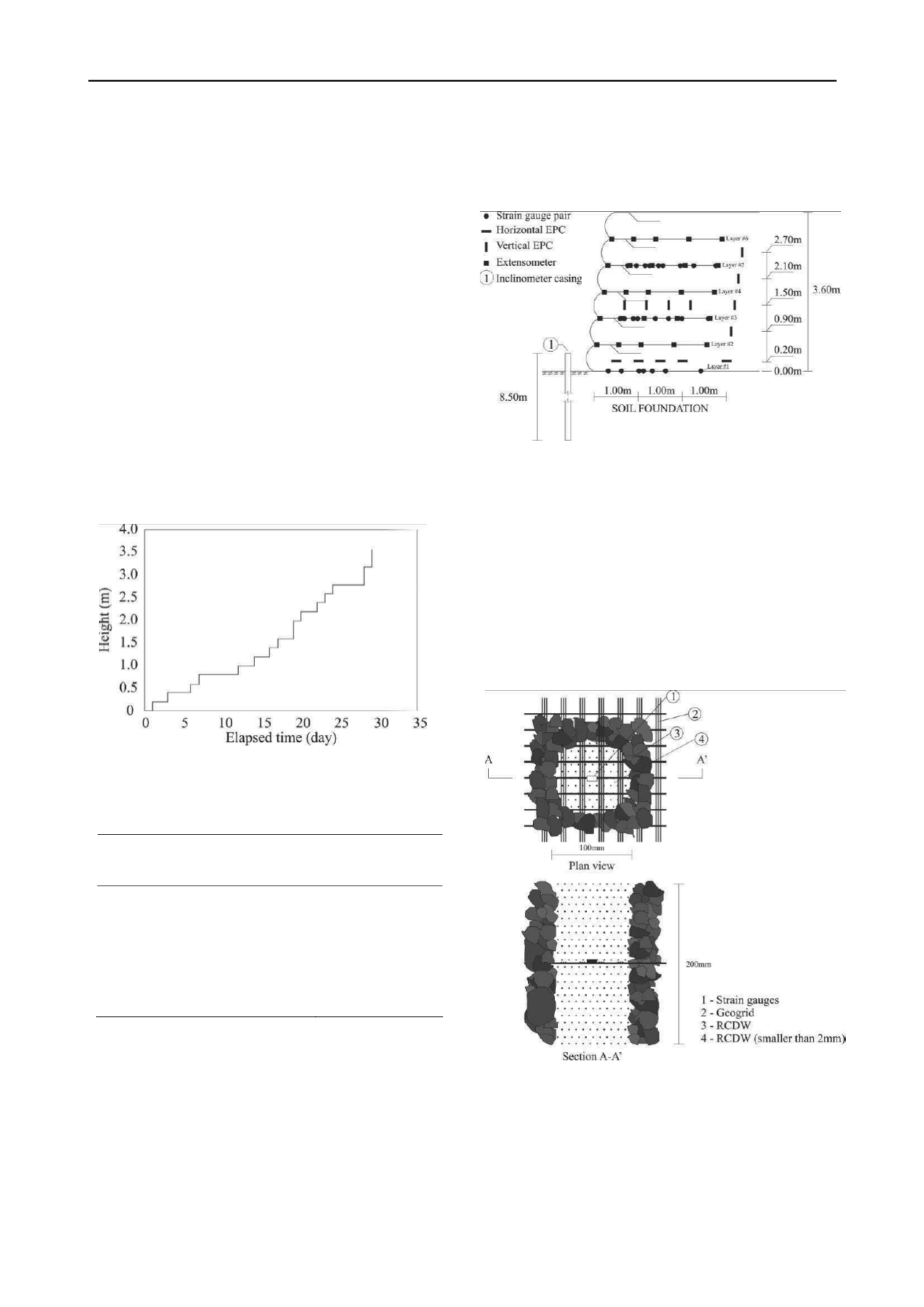

Figure 5 shows the instrument distribution profile.

Figure 5.Instruments distribution profile.

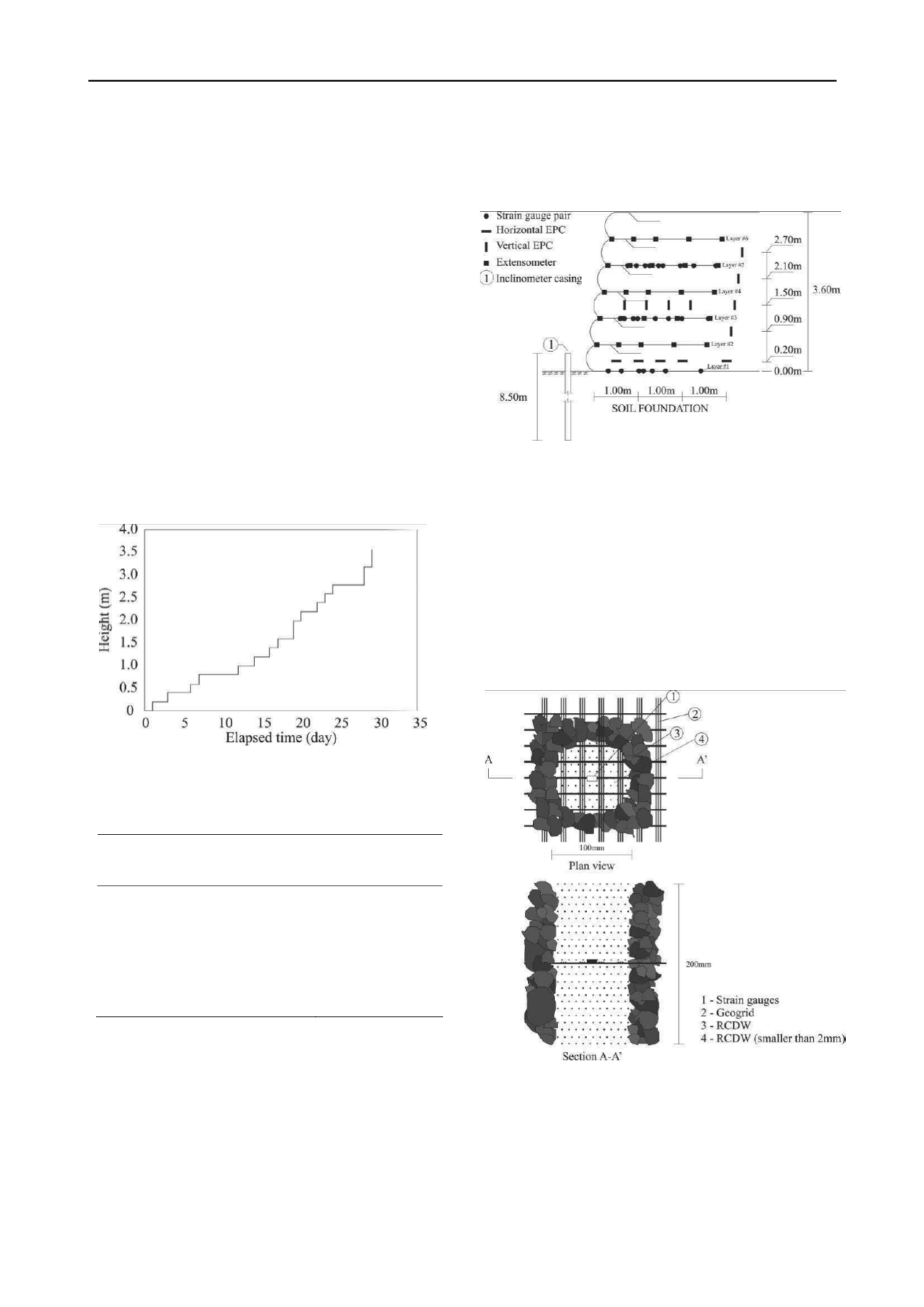

Additional procedures were necessary to protect the

instruments devices against mechanical damages during the

walls construction. Because of the presence of coarse grained

particles (Figure 2), the installation of the instrumented geogrid

layers and earth pressure cells (EPC) were carried out using fine

grained particles around the instruments. PVC tubes were used

to create a region with selected fine RCDW - smaller than 2mm

around EPC and strain gauges. Figure 6 presents a scheme of

the region around strain gauges after geogrid layer installation

process.

Figure 6.Region around strain gauges (wall #1).

The data recording after the walls construction revealed that

just one strain gauge was mechanically damaged, which

correspond to a survival level of 98% for installed strain gauges.

This survival level kept stable until the end of research program

even though the rainy seasons in Brasília. It was observed that

all EPC survived to installation process but not to the first rainy

season. After 110 days, all EPC failed.

Outward displacements of the walls faces during

construction were measured. It was observed for the wall #1