3256

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

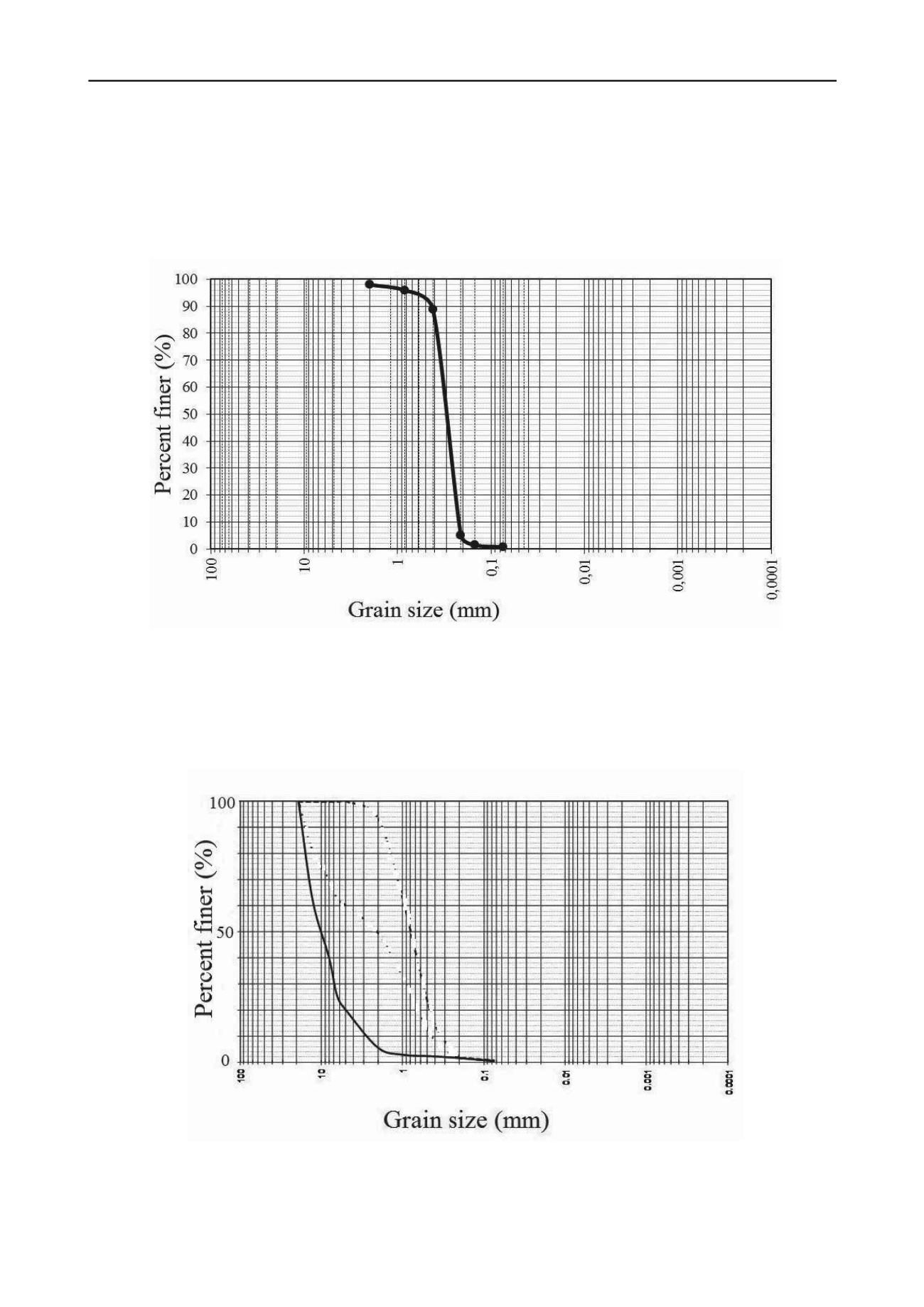

maximum and minimum void ratio of 0.85 and 0.54

respectively. D

60

of the sand used is 0.35mm and the internal

friction angle was found 41. Considering the weight proportions

of cement and glass foam, mixtures with different weight ratios

of cement, which is used as the binding material, and glass

foam, which is regarded as the main component having the

largest volume ratio in the mixture, were prepared. Cement and

water were mixed first, sand was added next if denoted in the

design, and after these components make up a rather

homogenous mixture, glass foam is added to the mixture and

stirred till homogeneity again.

Figure 1. Grain size distribution curve for the sand used in the experiments.

When the 7-day experimental results of the mixtures that

were produced using different sand ratios was examined, it has

been observed that the optimum results were exhibited by the

specimens which has equal sand and glass foam quantity and

when cement over foamed sand mixture ratio is two. The

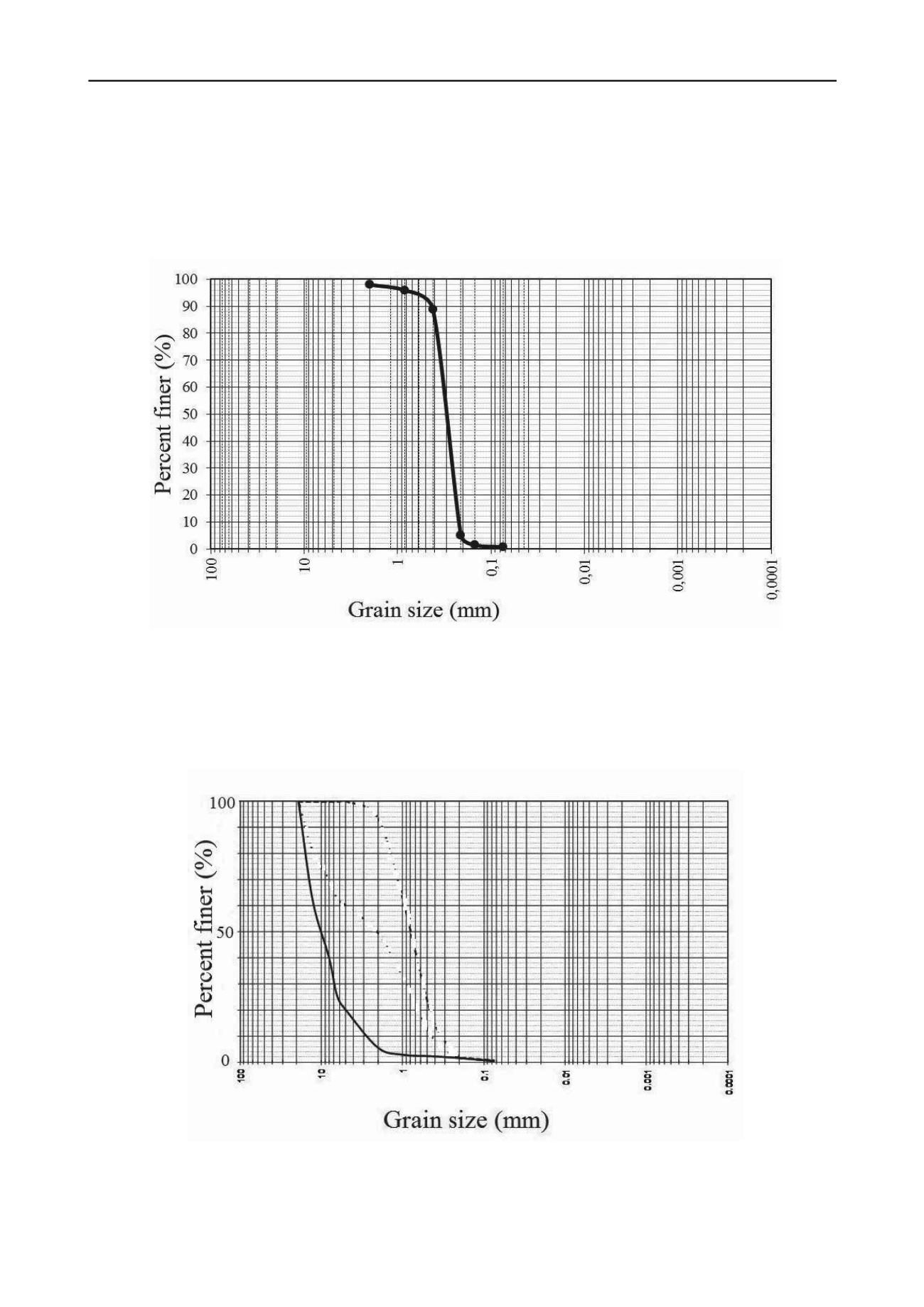

water/cement ratio used is 0.45. Figure 2 shows the grain size

distribution curve for the glass foam used in the experiments.

The average value of the saturated unit weight of the glass foam

mixture was found as 8.83 kN/m

3

.

Figure 2. Grain size distribution curve for the glass foam used in the experiments.

Figure 3 shows the cement, sand and glass foam mixture

sample used in the unconfined compression test. The average

value of the typical 7-day unconfined compression strength of

the mixture was determined as 0.75 MPa while the average of

the 28-day unconfined compressive strength was 0.91 MPa.

Figure 4 shows the results of these tests, as can be seen from the

figure with time the strength of the sample increases. The CBR