3264

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

3 23.

d

Table 1. Material’s symbols

Material

% Soil

% MSW fly ash

Symbol

Soil

100

0

S

MSW fly ash

0

100

CV

Mixture 1

60

40

S60/CV40

Mixture 2

80

20

S80/CV20

1

k k k RM

r

d

RM

3.2 Experimental tests

3.2.1 Chemical and physical characterization

Tests such as X-Ray Fluorescence, Organic Matter Content,

Lixiviation and Solubilization; Granulometric Analysis and

Atterberg’s Limit, MCT Test and Proctor Compaction Test

were conducted.

3.2.2 Resilient modulus test

The tests were performed according to standardized test in the

Geotechnical Laboratory of Federal University of Rio de

Janeiro, into molds of 10 x 20 cm compacted at optimum

moisture obtained in the compaction test.

In the cyclic load triaxial test, deviator stresses are applied in

the sample top, always in the compression direction, furthering

a load and unload, whereas the minor principal stress remains

constant.

Each sample was subjected to eighteen stresses states were

applied, with principal minor stress ranging from 0,021 to 0,137

MPa and deviator stress ranging from 0,021 to 0,412 MPa.

The Resilient Modulus (M

R

) of soil is the relationship

between the deviator stress (σ

d

) applied repeatedly in a sample

of soil in triaxial test and the corresponding specific recoverable

or resilient strain (ε

r

). As shown in Equation 1 (AASHTO

TP46-94 1996).

(1)

Where:

M

R

: resilient modulus;

σ

d

: cyclic deviator stress (σ

1

- σ

3

);

ε

r

: resilient strain (vertical).

The composite model used in this study relates the resilient

modulus of minor principal stress and deviator stress, as shown

in Equation 2.

(2)

Where:

σ

3

: minor principal stress;

σ

d

: cyclic deviator stress (σ

1

- σ

3

);

k

1

, k

2

and k

3

: correlation coefficients, derived from results of

laboratory tests.

This model was chosen because it presents bigger correlation

coefficients to the incorporating the minor principal stress and

the deviator stress influence. The nonlinear least squares model

estimation was utilized to obtain the correlation coefficients.

In order to evaluate the influence of cure time, optimal water

content samples were prepared and next rolled into hermetically

closed plastic bags for 7 and 21 days. Soon afterwards, these

were proceeded to the resilient modulus tests.

3.2.3 Permanent deformation test

The tests were performed according to Guimarães (2009), using

the same molds used in the Resilient Modulus Test. A total of

500,000 load cycles were applied for each specimen.

Three tests were conducted in the Mixture S60/CV40,

in the condition of maximum dry density, at stress levels shown

in Table 2.

Table 2. Permanent deformation tests

Test Number

σ

3

(MPa)

σ

d

(MPa)

1

0,098

0,294

2

0,118

0,353

3

0,098

0,392

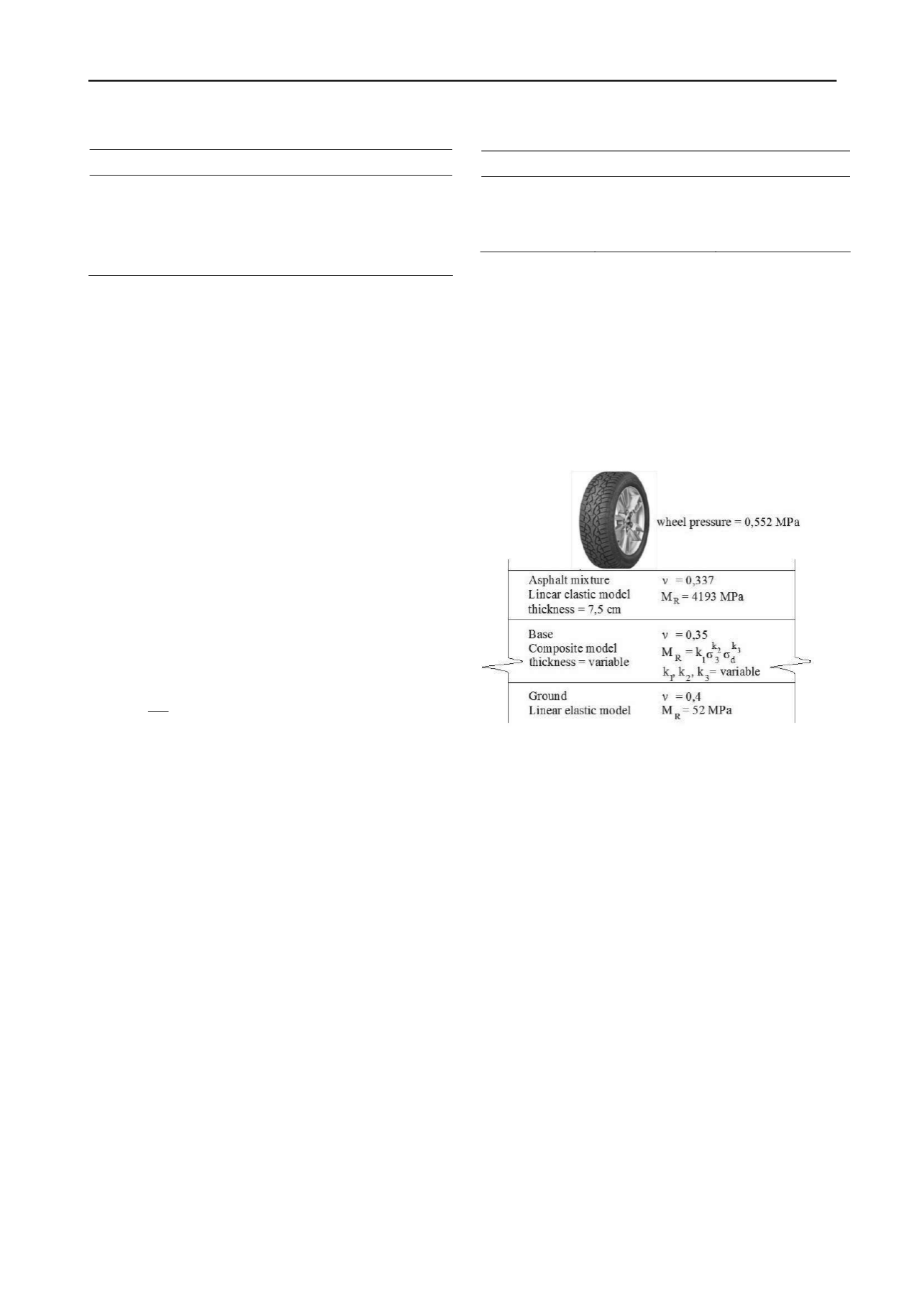

3.2.4 Pavement design

A pavement structure was assumed (Figure 1) considering Rio

de Janeiro’s weather, with the purpose of exploring the effects

of adding MSW fly ash in soil on pavement project one. The

thickness and mechanical properties of the coated asphalt and

subgrade remain constant, so that only the the thickness of the

base may be modified, according to the parameters of resilience

for each material. As for the mechanistic-empirical analysis, the

computer program SisPav (Franco, 2007) was used. Bernucci

(1995) indicates for Brazilian low traffic roads an N value of

10

4

to 10

6

should be used. Thus, in this study, N value of 10

5

was assumed.

Figure 1. Pavement structure adopted.

4 RESULTS AND DISCUSSIONS

From the test conducted, the characteristics and effects of the

addition of MSW Fly Ash into soil were studied.

4.1 Chemical characterization

The main chemical components of soil, which are normally

found in residual soils, are SiO

2

, Al

2

O

3

and Fe

2

O

3

, such as

showed in the Table 3. Lixiviation and Solubility tests

performed according to Brazilian standards NBR 10005 and

NBR 10006 for MSW fly ash and soil stabilized with 40% fly

ash content. The mixture is classified non - dangerous and non-

inert (Vizcarra 2010).

4.2 Physical characterization

MSW fly ash and mixtures can be noted as follows: first, the

Atterberg Limits for pure MSW fly ash could not be performed

due to the behavior of granular material, which during the test

did not show plastic characteristics to their achievement.

Second, the inclusion of MSW fly ash decreases the liquid limit

and plasticity index, and increases the plastic limit of soil.

According the classification MCT (Nogami & Villibor

1995), the soil is classified as NG’ behavior "non-lateritic-clay."

When compacted under the conditions of optimum moisture

content and maximum dry unit weight for normal energy

compaction, these soils present characteristics of traditional

highly plastic and expansive clays.

The use of these soils is related to restrictions resulting from

its high expansibility, plasticity, compressibility and contraction