3273

Technical Committee 307 /

Comité technique 307

As mentioned above, Al leaches during H

2

O

2

percolation.

The deformation of the mechanical bridging by Al leaching

causes at the same time as organic matter decomposition. To

distinguish the influence of Al leaching on the mechanical

deformation from organic matter decomposition, shear

characteristics of the DWS for which the mechanical bridging

had been decomposed by leaching using distilled water adjust

pH 4.0 using HNO

3

which was almost same pH as H

2

O

2

solutions were also investigated in CASE 5 to 8. In acidic

condition, humic acid almost remains in DWS, although fulvic

acid is decomposed. In CASE 7 and 8, samples previously

submerged in HNO

3

repeatedly, and the specimens were

produced by dynamic compaction using the decomposed

sample.

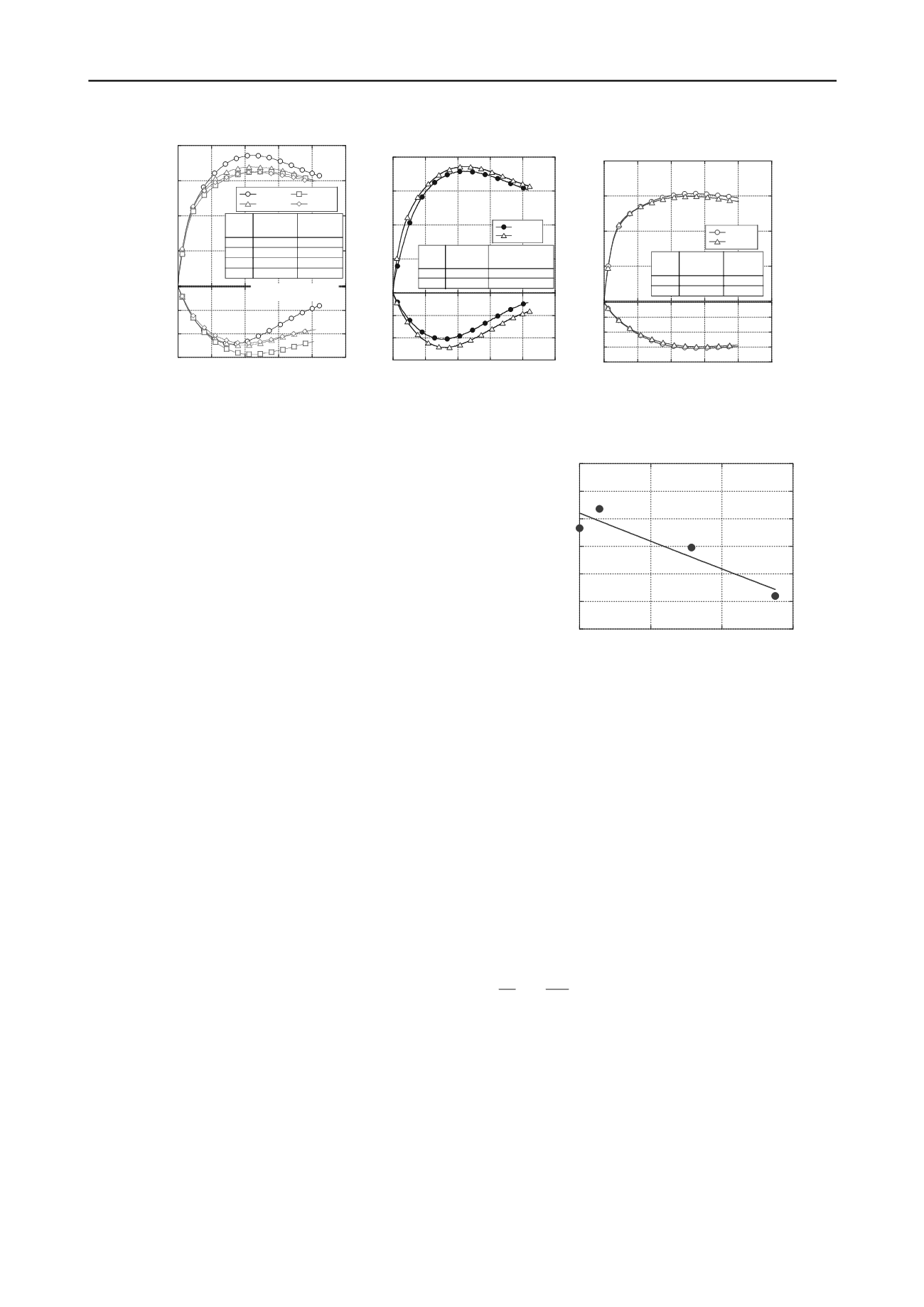

3.2 Experimental results

The respective relations between the deviator stress and the

volumetric strain to axial strain at 50 kPa of confined pressure

was presented in Fig. 6. Volumetric swelling was slight in the

large axial strain range, and the maximum deviator stress

decreased concomitantly with the decrease in ignition loss. For

the cases of distilled water percolation, the influence of

percolation volume was not obtained. The larger dry density

typically showed higher shear strength. For the cases of pH 4.0

water submergence, maximum deviator stress slightly decreased

and cumulative Al release increased with the increment of

submergence. The influence of Al release on shear strength was

relatively smaller than those of organic matter decomposition.

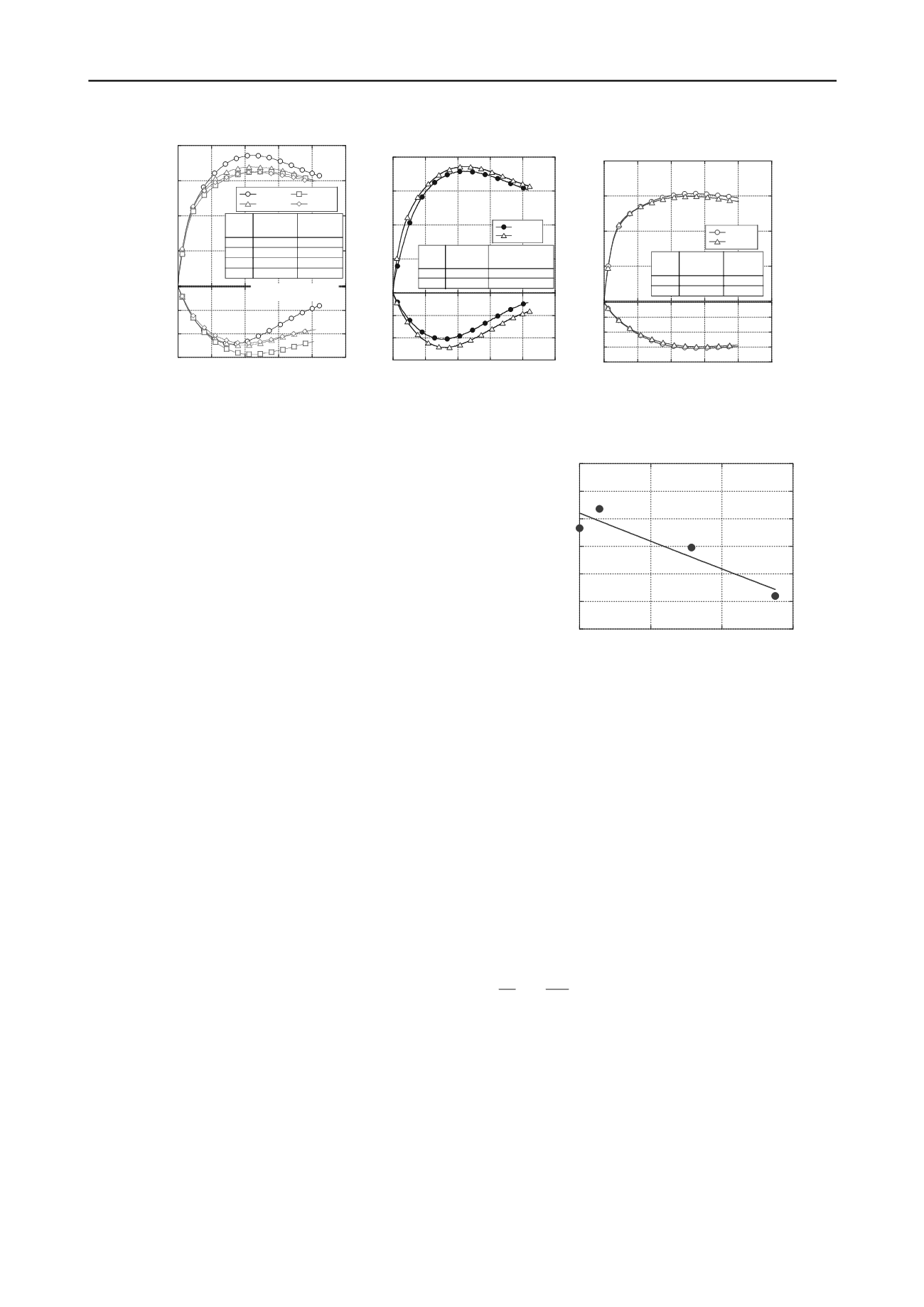

The internal friction angle and the cohesion of DWS after

organic matter decomposition were, respectively, 38.6° and 0

kN/m

2

. The mechanical bridging and the organic matter

decomposition do not influence DWS cohesion. Assuming that

the cohesion is 0 kN/m

2

, the relation between the internal

friction angle and the decomposition rate of organic matter was

presented in Fig. 7. After the organic matter was decomposed

until 1.38%, the internal friction angle decreased from

approximately 38.8° to 37.6°. For the cases of pH 4.0 water

submergence, the internal friction angle decreased from 37.2° to

36.7° although the dry density was smaller than any others.

Consequently, results show that the decomposition of organic

matter remarkably affects to the DWS shear strength. Chemical

bonding between particles by the cementation of organic

compounds is possible (Mitchell and Soga, 2005). Presumably,

the strength of DWS clods decreased because the bonding was

lost through organic matter decomposition.

4 PREDICTION OF SHEAR STRENGTH TRANSITION

Al release and organic matter decomposition cause the

decrease in shear strength of DWS. To evaluate the durability of

DWS as a geo-material, this study related the change of its shear

strength the decomposition to the substantial period in

geotechnical works such as road infrastructures.

0

50

100

150

200

CASE1

CASE2

CASE3

CASE4

Deviator stress (kN/m

2

)

Ignition loss

(%)

Dry density

(Mg/m

3

)

CASE

17.51

0.821

1

17.77

0.825

2

17.12

0.815

3

16.53

0.823

4

1

2

3

0

5

10

15

20

25

Volumetric strain (%)

Axial strain (%)

CASE 2,3,4: decomposition

by hydro peroxide solution

0

50

100

150

200

CASE 5

CASE 6

Deviator stress (kN/m

2

)

Percolation volume

(mL)

Dry density

(Mg/m

3

)

CASE

500

0.817

5

3000

0.821

6

1

2

3

0

5

10

15

20

25

Volumetric strain (%)

Axial strain (%)

0

50

100

150

200

CASE 7

CASE 8

Deviator stress (kN/m

2

)

Al release

(mg/kg)

Dry density

(Mg/m

3

)

CASE

0.130

0.783

7

0.192

0.795

8

1

2

3

4

0

5

10

15

20

25

Volumetric strain (%)

Axial strain (%)

(a) H

2

O

2

percolation (b) distilled water percolation

(c) pH 4.0 water submergence

Figure 6. Relation between deviator stress and axial strain in triaxial compression tests using decomposed DWS.

37.0

37.5

38.0

38.5

39.0

39.5

40.0

0

0.5

1

Internal friction angle (deg.)

Decomposition rate of organic matter (%)

1.5

Figure 7. Relation between internal friction angle and

decomposition rate of organic matter.

4.1 Shear strength transition addressing decomposition of

mechanical bridging

Decomposition of the mechanical bridging is described as Al

leaching behavior. When DWS is used as a subgrade material

under groundwater level, Al diffusively leaches. Therefore, the

Al leaching behavior is described as a diffusion equation based

on the Fick’s law.

2

2

x

C D

t

C

e

(1)

In that equation,

D

e

is the coefficient of diffusion [m

2

/s],

C

is

the concentration [mg/L], and

x

signifies the distance from

particle surface [m]. An initial condition and boundary

conditions are shown as follows.

0

1

0

;

,0 ,

;0 ,0

;0 ,0

C C x

tC C x

t

C C x

t

where

C

0

represents the internal concentration of material

[mg/L], and

C

1

is the constant concentration [mg/L]. Assuming

C

0

is sufficiently higher than

C

1

, the cumulative release

M

is

derived.