3277

Technical Committee 307 /

Comité technique 307

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

to be completely wrapped in the

geo

during the execution

of such operations is essential.

f

han

l

con

plan, is

r the top of

the

in at

either side to provide around half a bale width of overlap.

ler to the layer to vibrate the fill into the voids

(Fi

ve or

below the tyre bale layer must also be taken into account.

consolidated silts and clays, and soft predominately mineral

soils (albeit with exceptions). A geotextile helps to spread the

foundation load. Often the repair or reconstruction of an

existing road over soft ground is required as a result of

differential settlement which leaves an uneven surface with poor

ride quality and an increased risk of flooding. The placement of

material to raise and regulate the pavement surface increases the

formation load causing further differential settlement;

replacement of the existing material is thus necessary.

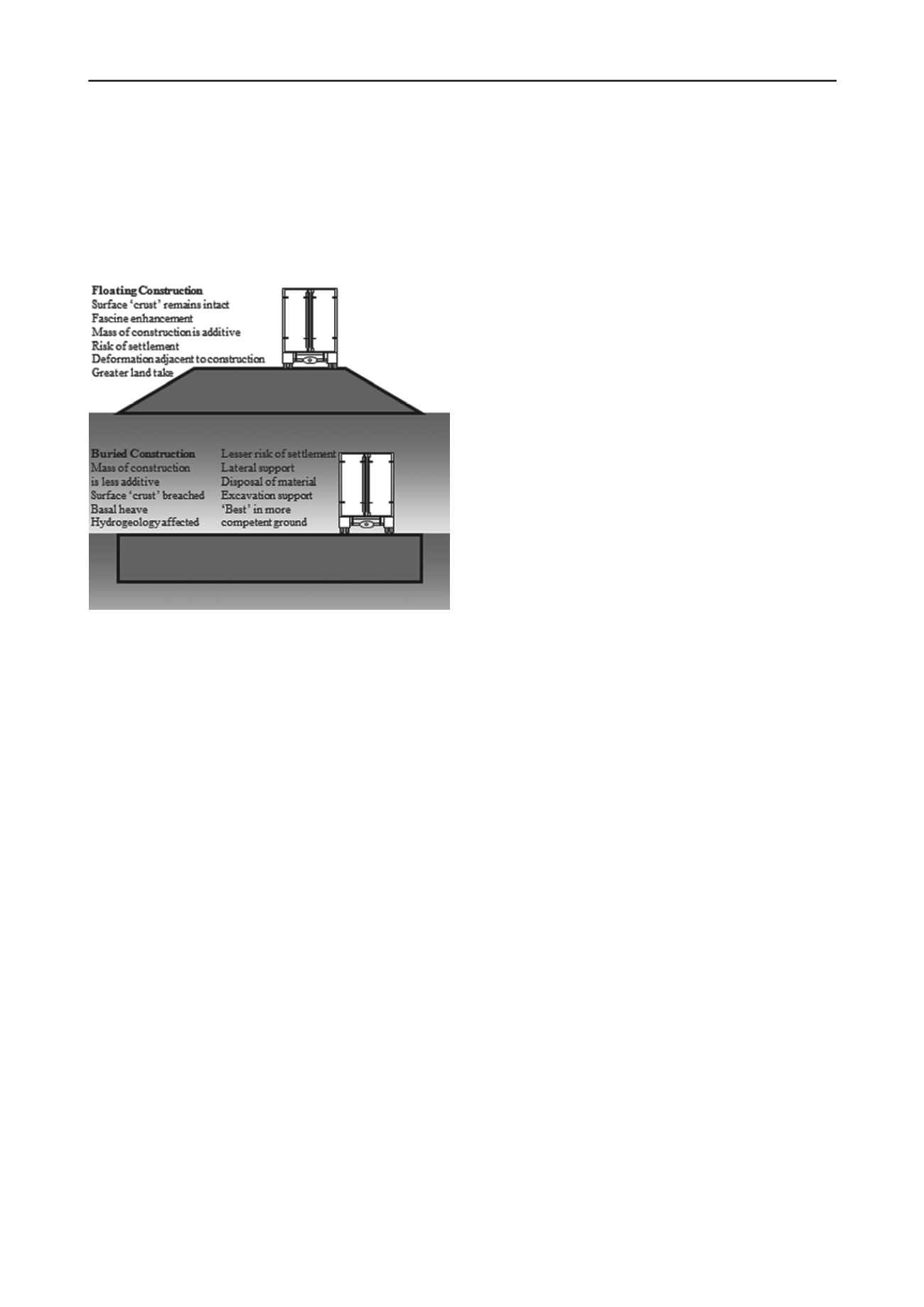

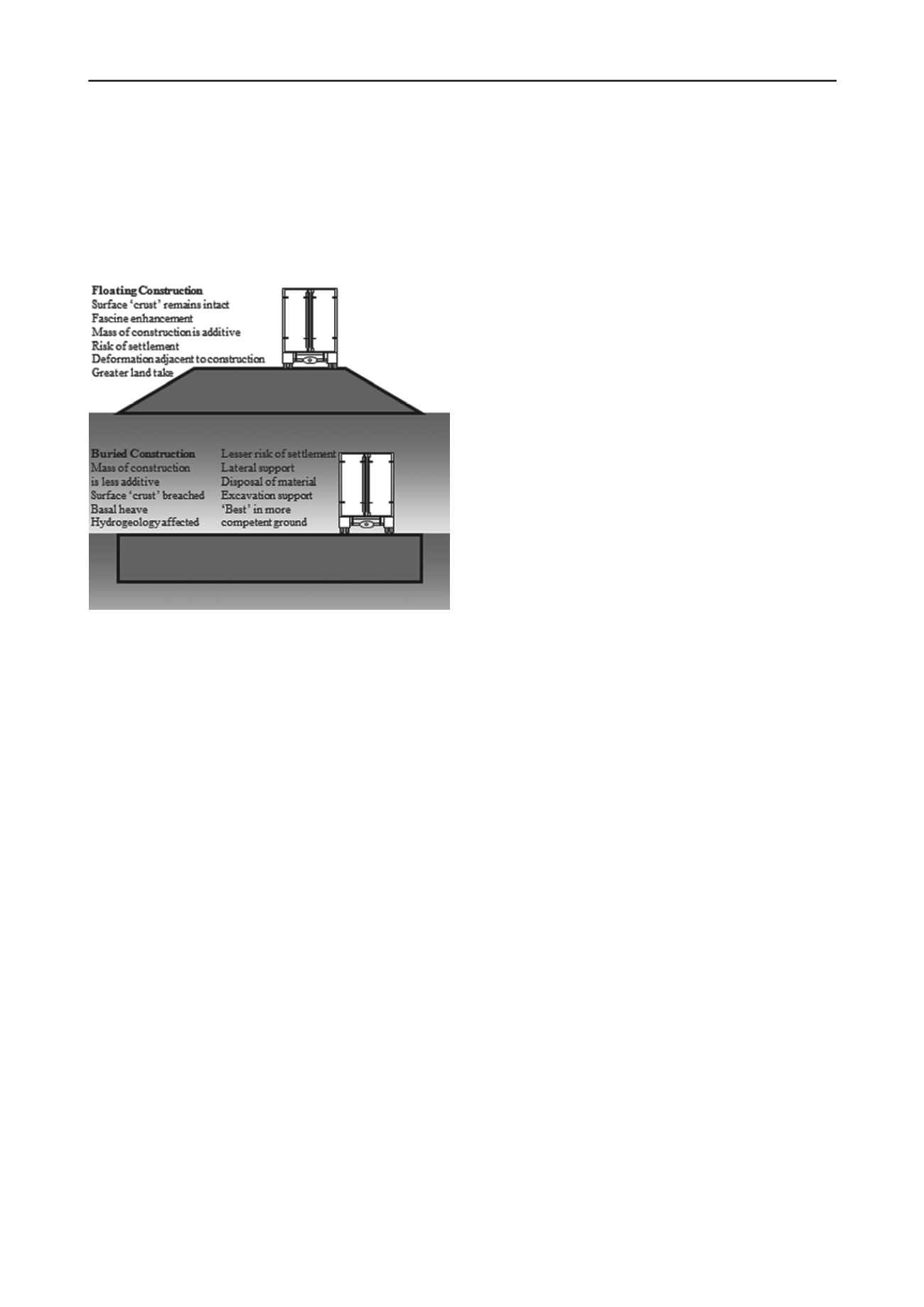

Figure 2. Advantages and disadvantages of floating construction (top)

and buried construction (bottom).

4 CONSTRUCTION APPROACHES

The construction and rehabilitation of low-volume roads over

soft ground is an ideal application for tyre bales. While there is

currently little information to prove their use with higher traffic

levels (in excess of a few hundred vehicles/day AADT) there

are no pressing reasons why such uses should not be successful.

Low-volume tyre bale roads have been successfully

constructed both above and below ground. A geotextile

separator is used between the in-situ soil and the tyre bales,

usually with a regulating layer of sand. The geotextile helps to

prevent differential movement of the bales during and after

construction. The decision as to whether the construction should

be above or below ground is an important determinant of the

approach to the design and construction.

Analytical input for low-volume road design on soft ground

is often limited. The strength and stiffness properties of the soil

involved are usually at or close to the lower limit of

measurement, rendering input parameters subject to large errors.

The sampling process may also disrupt the soil structure leading

to values lower than the field condition. Accordingly many

roads are designed on an empirical, specification-led basis.

The following sections summarises the main construction

steps and issues and offer guidance based upon experience of

successful projects and established good practice in constructing

low-volume roads over soft ground using tyre bales. Further

details are given by Winter et al. (2006) and Anon. (2007).

4.1

Excavation and preparation

For buried construction, excavation is the first construction

activity. Low ground-pressure, tracked plant is preferred as is

working in drier weather when the moisture content of the soil

is minimised and strength and stiffness are maximised.

A suitable geotextile should be installed either at ground

surface level or in the excavation followed by a regulating layer

of sand if required. All geotextile-to-geotextile interfaces should

have an overlap of 1m. The use of a geotextile has a number of

advantages including aiding working conditions in soft soils,

strengthening the structure by tying together the assembly of

bales, and providing separation between the bales and the

subsoil and thus preventing the ingress of fines. Randomly

orientated, bonded, non-woven geotextiles have been found to

be effective. Their main function is separation, with strength

and resistance to clogging the most important properties.

Geotextile design procedures should reflect local standards. The

geotextile should be placed in the base of the excavation, or on

the cleared ground. Sufficient excess should be allowed at either

side to allow the bale assembly

textile with a 1m overlap.

Rapid cellular construction minimises excavation size,

exposure of the soil to weather and the likelihood of side slope

failure. Bale sizes mean that excavations are unlikely to exceed

1m, but an assessment of the possibility of sidewall collapse and

the associated risks to workers and others

4.2

Placement and alignment

Tyre bale handling must incur the minimum risk of damage to

the steel tie-wires. The most successful means of handling tyre

bales has been found to be a ‘loggers’-clam’, which can be

attached to a variety of hydraulic equipment and provides an

appropriate lift-and-place methodology while allowing the bale

to be rotated to the correct alignment. Alternative forms o

dling bales include brick-grabs and forklifts (Anon. 2007).

The manufacturing process renders tyre bales inherently

heterogeneous. Information on the relative stiffness in each of

the three directions is not currently available. Tyre bales exhibit

a high stiffness when loads are applied vertically to the 1.3m by

1.55m plane (Figure 1); accordingly they are usually installed as

illustrated in Figure 1 for applications that attract high vertical

loads such as road foundations. The 1.55m by 0.8m plane is

perpendicular to the load applied during manufacture and it is

recommended that it is aligned perpendicular to the longitudina

fining stresses (i.e. with the tie-wires in line with the road.

While there are different layout options for the two-

dimensional placement of tyre bales (i.e. in a single layer) a

straightforward ‘chessboard’ pattern, as viewed in

generally the easiest to construct and is recommended.

A regulating layer of sand is normally required between the

top of the tyre bales and the geotextile wrapped ove

layer to help eliminate small variations in level.

The foregoing assumes that a single layer of bales is to

support the road. If two or more layers are required then the

second layer should be placed on top of the first, stepped

4.3

Filling of voids

The sub-rectangular shape of tyre bales means that voids remain

at the corners of each bale even when they are butted up against

one other. The design generally requires the stiffness and

stability of the structure to be maximized and thus the voids

should generally be filled (Figure 3). Coarse sand has been used

successfully as have single-sized aggregate pellets. Crushed

glass may be less likely to clog or arch than sand when wet, but

is expensive. The most effective method of ensuring that the

voids are filled has been found to be to bulldoze a 150mm to

300mm layer on top of the bale layer and then to apply a

vibrating rol

gure 3).

The fill material affects the density of the structure, with the

voids taking up an estimated 4% to 8% (Anon. 2007) of the

nominal rectangular bale volume, and must be allowed for in

design calculations. The effects of regulating layer(s) abo