3276

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

Substances that could potentially leach from tyres are

already present in groundwater in developed areas. Studies

suggest that leachate levels generally fall well below allowable

regulatory limits and have negligible impact on water quality in

close proximity to tyres (Hylands & Shulman, 2003) and that

rates of release decrease with time (Collins et al. 2002).

Similarly there is no evidence of significant deterioration of

tyres buried in the ground for decades (Zornberg et al. 2004).

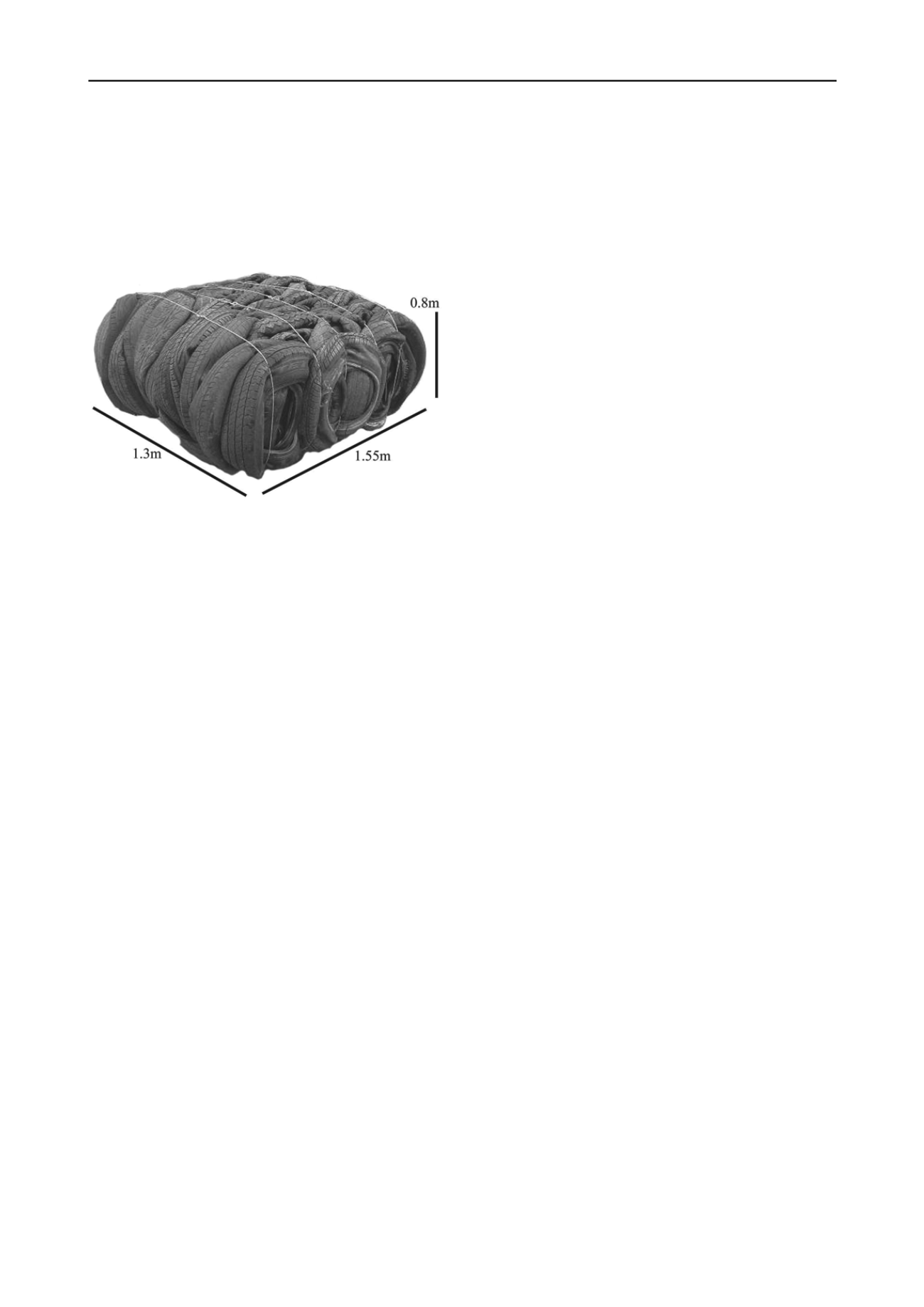

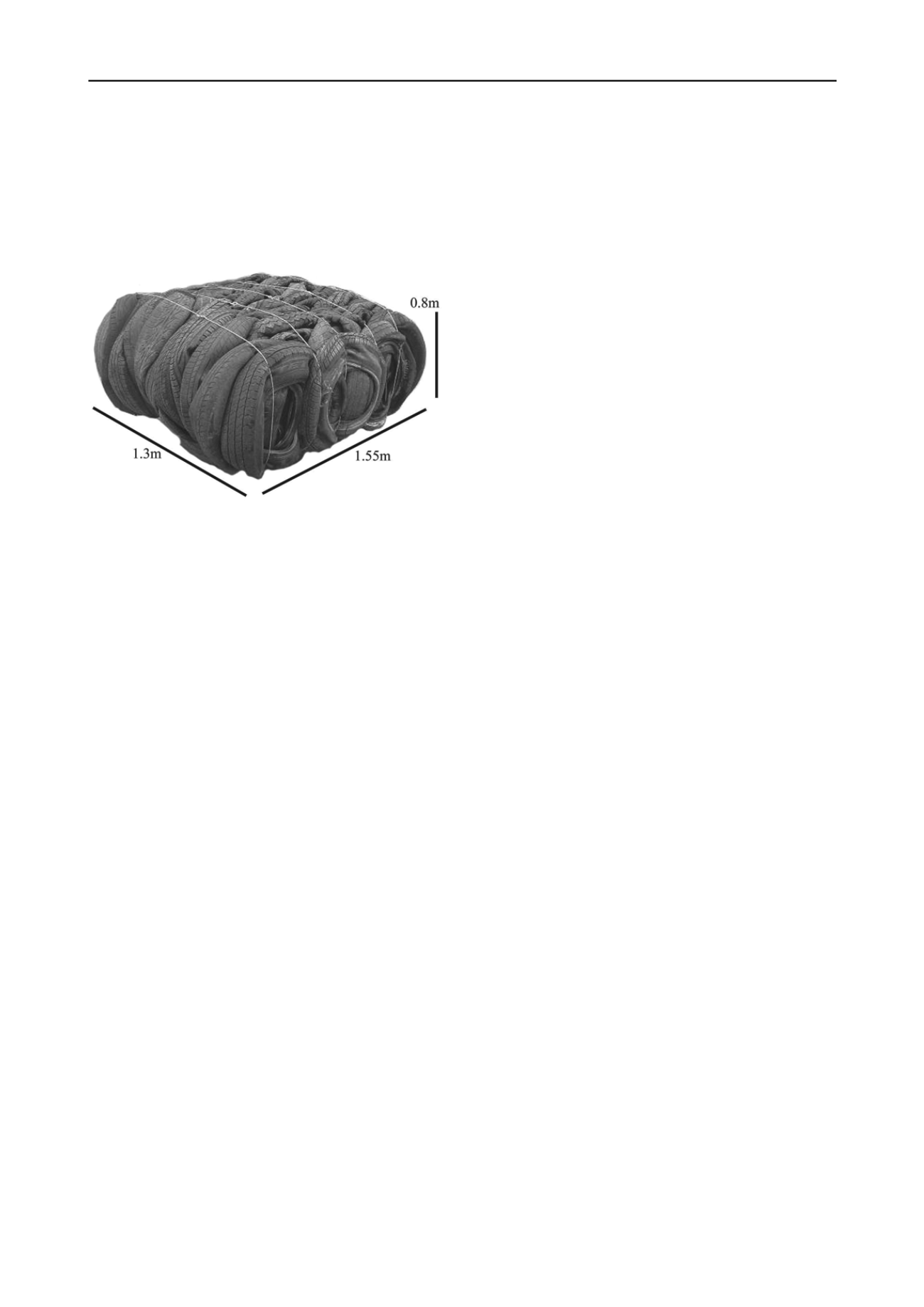

Figure 1. A typical tyre bale with dimensions.

Spontaneous fires in whole tyre dumps are not known to the

author. In the USA, while combustion due to sparks from

agricultural machinery and lightning have been reported, most

observers suspect some form of arson in almost all cases. Baling

whole uncompressed tyres reduces the volume by a factor of

four to five, greatly reducing the available oxygen as well as the

exposed rubber surface area as tyre-to-tyre contacts are formed,

without exposing any steel reinforcing in the tyres. The

exothermic oxidation reaction potential is significantly lower

than for whole tyres and the risk of spontaneous combustion

from tyre bales is viewed as extremely low. A modelled storage

condition for a 17.5m by 6.0m by 3.0m volume of bales needed

to reach and maintain a temperature of 188

o

C for 39 days before

spontaneous combustion became possible (Simm et al. 2005). In

contrast reports have been made of internal heating of tyre shred

and of apparently spontaneously combusted fires in large

volumes in the USA (Sonti et al. 2000). Further details of tyre

bale properties and behaviours are available (Anon. 2007).

Tyre bale use reflects positively on the sustainable use of

materials and energy and other factors. In the last decade the

application level has moved from domestic works/river bank

erosion projects to slope failure repairs adjacent to a major

Interstate Highway in the USA (Winter et al. 2009) and the

construction of a lightweight embankment as part of the A421

A1-M1 link road construction which won the British

Geotechnical Association’s prestigious Fleming Award.

An adequate supply of tyres, and the resources to turn them

into bales must be secured prior to the commencement of a

project. As bales are around ¼ to

⅕

the volume of whole tyres it

can be particularly difficult to gauge the volume of bales that

will result from a stockpile of tyres. A series of nomograms was

developed by Winter et al. (2006) and further refined (Anon.

2007) to rapidly describe the number of bales required to fill a

given volume, the number of tyres likely to be used in their

manufacture, and the number of eight hour (two man) shifts

required to manufacture those tyre bales.

Tyre bales costs are similar to those of other road foundation

materials (e.g. UK Type 1 Sub-Base). However, the main

advantages of tyre bales are the much reduced plant and labour

costs resulting from their rapid placement (Winter et al. 2006).

2.2

British Standard

The tyre baling industry in the UK reached a level of maturity

with the production of a British Standard Publicly Available

Specification (PAS) for tyre bales (Anon. 2007). It assists

manufacturers to produce high quality, consistent and traceable

products for use in construction by responsible and competent

organizations, and demonstrate high and consistent quality via a

Factory Production Control process. It covers activities and

aspects of tyre bale manufacture, storage and use in

construction, including: receipt, inspection and cleaning of

tyres; handling and storage of tyres; production of bales

(including a system for measuring and labelling bales to ensure

traceability); handling and storage of the bales; transport,

storage on site and placement of the bales; and factory

production control.

Guidance is given to construction professionals in

formulating preliminary design and construction proposals. Not

all aspects of design are covered but information not available

from other engineering documents is given. This includes: the

measurement of properties; engineering properties and

behaviours associated with tyre bale use in construction;

example applications; and end of service life options.

3 METHODS OF CONSTRUCTION

There are two main approaches to road construction over soft

ground: above ground (floating); and below ground (buried).

Both use large volumes of granular fill.

It is important to decide whether or not a crust in, for

example, peat may be breached or whether it must remain

intact. Figure 2 illustrates advantages and disadvantages of

floating and buried construction. The crust in peat will often be

formed from fibrous vegetation. Similarly, many normally

consolidated lowland clays in parts of Scotland and many

Scandinavian ‘quick clays’ will have a stiffer crust. In general

terms it is inadvisable to breach the crust of these materials and

thus floating construction is preferred to buried construction.

3.1

Floating construction

In areas of deep soft soil, replacement techniques are

unattractive as large volumes of material must be excavated,

transported and disposed at both monetary and environmental

cost. The surrounding soft material may create difficulties

related to excavation support, basal heave and other factors,

making the works uneconomic. Where the natural surface

‘crust’ is stiffer than the lower layers due to the presence of

vegetation, desiccation, compaction and other factors, the

surface may form the subgrade. Care is needed to ensure that

the crust is not compromised during construction and that as the

road is built the imposed loads are spread over a wide area.

In the past construction often utilised bundles of twigs

(fascines), usually two layers orientated at 90

o

, at subgrade level

to resist differential movement. For greater loads logs were used

on the fascines, working best for materials with stiff crusts (e.g.

fibrous peat overlying softer amorphous, or humified, peat). The

modern equivalent is a geosynthetic material; the use of tyre

bales or other lightweight fill on the geosynthetic/sand layer

lessens the applied load. The success of temporary surcharging

is often limited in very soft soils such as peat due to the

potential for long-term secondary and/or tertiary consolidation

and the potential to breach any overlying stiffer layer.

3.2

Buried construction

The removal and replacement of in-situ materials with new,

lightweight, fill is a costly option and may involve excavation

below the water table. However, sidewall lateral restraint adds

durable construction stiffness. The key to construction is to

ensure that the fill adds minimal load.

Buried construction may be preferred in more competent

materials, or in thinner layers of less competent materials for

which removal is an option. Such materials include normally