3272

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

mechanical bridging of flocculating agent: polyaluminum

chloride is frequently used in Japan. Some hydrophilic parts of

flocculating agent remain and bind clods as second binding,

then more than 10

-5

m diameter clods presumably form DWS’s

porous structure as shown in Fig. 1.

In this study, DWS was sampled in Ibaraki, Japan.

Approximate organic matter content of DWS was determined

by ignition loss tests. The ignition loss and fundamental

properties were listed in Table 1. Ignition loss of DWS was

17.6%

―

27.3%. The amount of humic and fulvic acids were

determind by alkaline and acid isolation (Ohkubo et al., 1998).

Specifically, humic acid content was dominant for DWS. It is

indicated that organic matter exists in as a solid part and a

bonding as well as the mechanical bridging. A main constituent

of polyaluminum chloride is Al

2

O

3

. Previous study has been

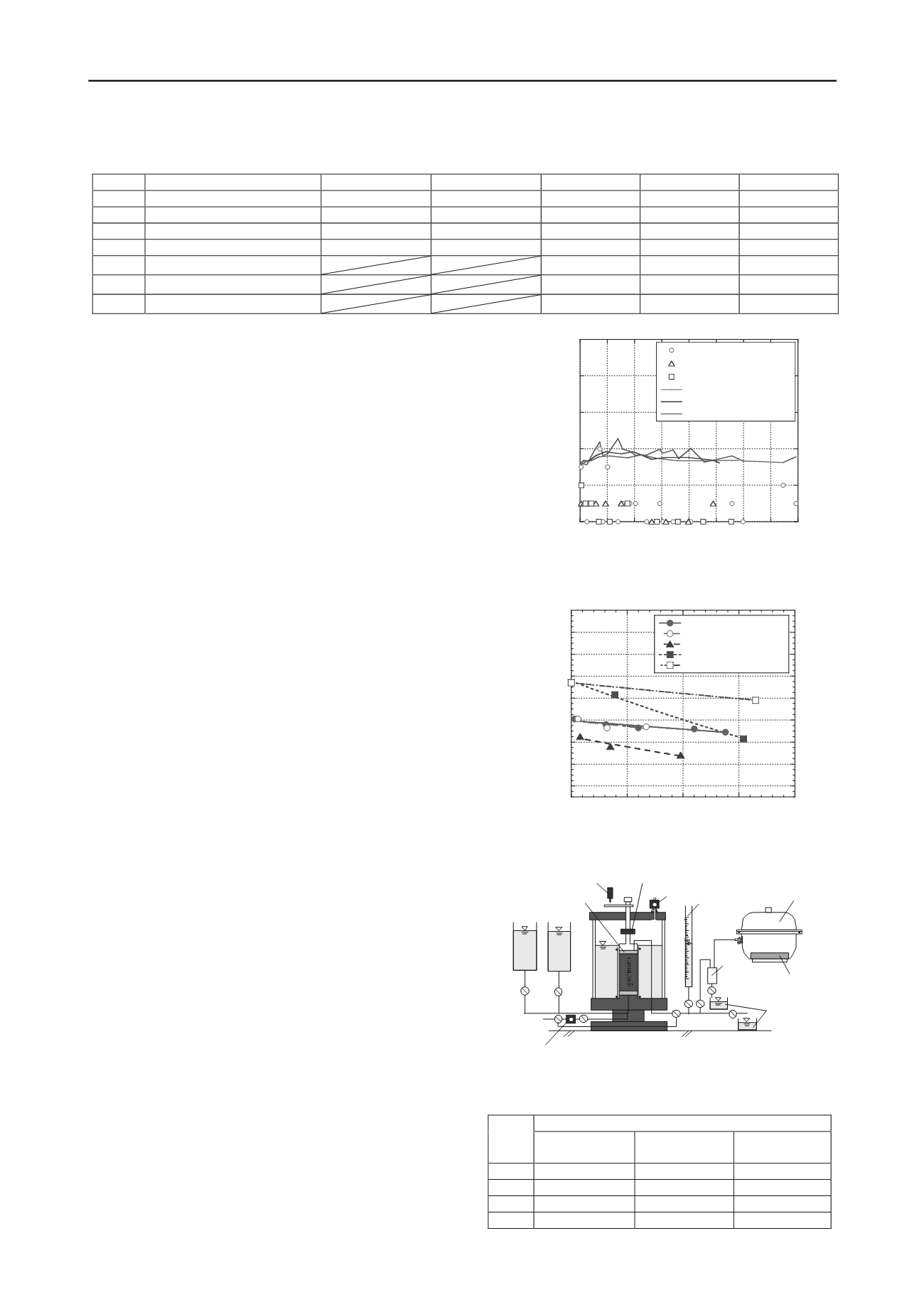

already confirmed Al leaching by column leaching tests in Fig.

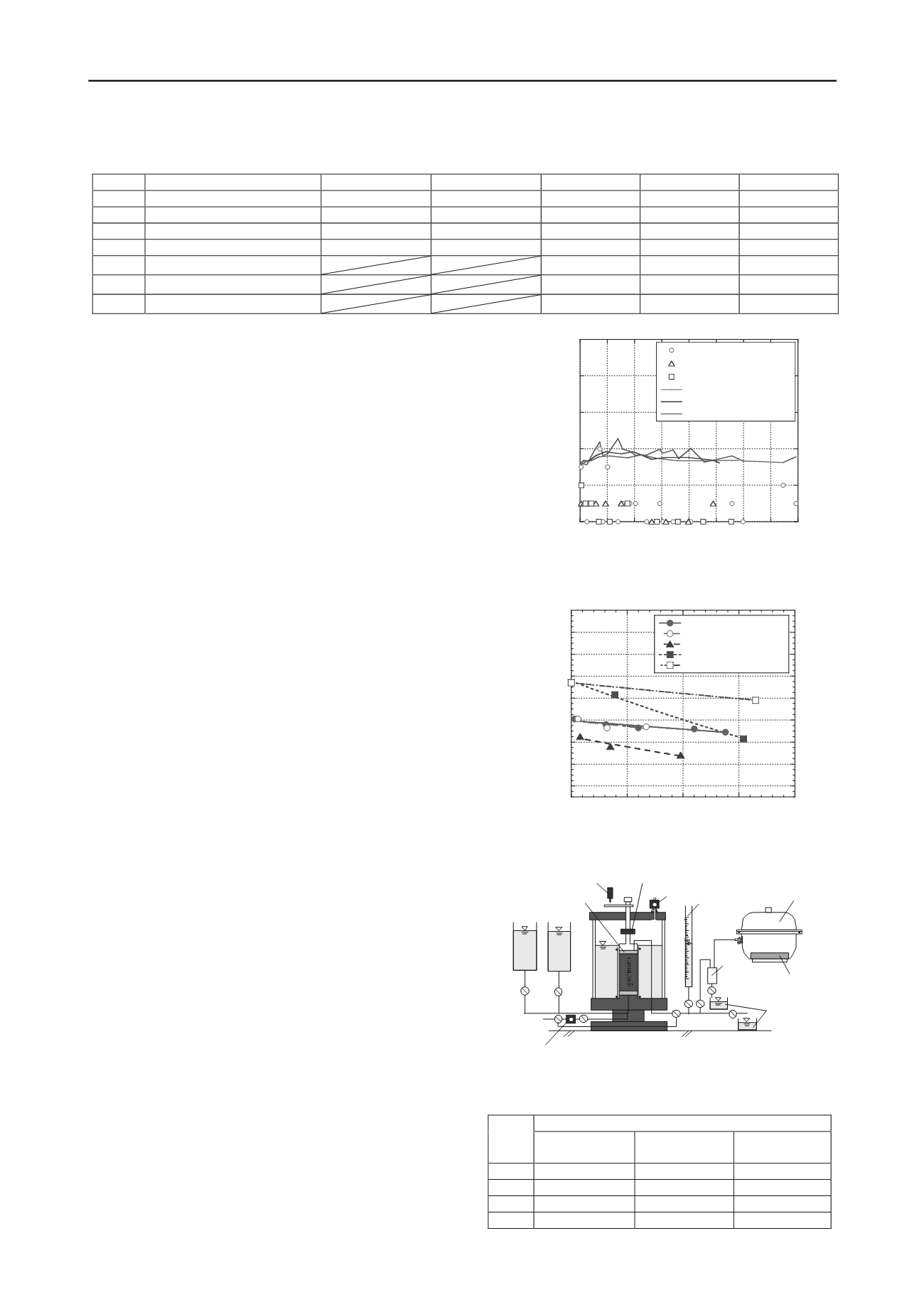

3 (Watanabe et al., 2009). Organic matter decomposition at 30

degrees has been confirmed in Fig. 4 (Watanabe et al., 2011),

which means the loss of DWS particles and binders.

Consequently, engineering properties of DWS after the

decomposition mentioned above are interest on a discussion of

DWS durability.

Table 1. Fundamental properties of DWS.

DWS

3 RELATION BETWEEN SHEAR STRENGTH AND

DECOMPOSITION

Shear characteristics of DWS after decomposition were

investigated to elucidate the necessity of the mechanical

bridging and organic matter on DWS’s structure. The DWS

which was mainly decomposed by H

2

O

2

solution was used in

triaxial compression tests.

3.1 Experimental procedure

Triaxial compression tests were executed using the DWS for

which the mechanical bridging and organic matter had been

decomposed by the H

2

O

2

solution. The apparatus for the triaxial

compression tests is portrayed in Fig. 5. The specimen had 100-

mm height and 50-mm diameter. Specimens were produced by

dynamic compaction using DWS-A. The dry density in CASES

1–4 was 0.815–0.825 Mg/m

3

which corresponds to compaction

degree 76%. First, the specimen was isotropically confined by

10 kPa. Then the H

2

O

2

solution (6%, 9%, 15%) was percolated

through the specimen by 10 kPa of water pressure. Specimens

in CASES 2, 3 and 4 were decomposed by the H

2

O

2

solution.

During H

2

O

2

percolation, CO

2

was generated by oxidation. The

CO

2

continuously flow into the sealed desiccator, and the CO

2

concentration was measured using a wireless CO

2

sensor. The

completion of oxidation was confirmed as the CO

2

concentration converged, which prevented partial saturation of

the specimen during shearing. The decrease in organic matter by

H

2

O

2

has been investigated in Table 2. The discharged water

was collected, and Al concentration was measured. The distilled

water was percolated after H

2

O

2

percolation, and more than

0.95 of the B-value was confirmed for specimen saturation. The

isotropic consolidation pressure was 50 kPa or 100 kPa. The

triaxial tests were executed in the drainage condition with

0.1%/min of the strain rate.

Particle density of soil (Mg/m

3

)

Liquid limit (%)

Plastic limit (%)

Ignition loss(%)

Fulvic acid (%)

Humic acid (%)

A

2.58

224

145

17.6

0.039

3.14

B

2.61

178

104

18.8

0.032

2.39

C

2.52

269

151

26.6

0.034

9.27

D

2.45

113

91

27.3

0.040

4.31

E

2.54

17.1

0.016

1.20

F

2.65

22.1

0.049

3.90

G

2.45

19.1

0.036

5.14

0

0.02

0.04

0.06

0.08

0.1

0 5 10 15 20 25 30 35 40

[1] compaction degree: 92.1%

[2] compaction degree: 87.2%

[3] compaction degree: 77.2%

Al saturated concentration [1]

Al saturated concentration [2]

Al saturated concentration [3]

concentraiotn (mg/L)

Liquid per soild ratio (L/kg)

Al

Figure 3. Al concentration in column leaching tests (Watanabe et

al., 2009).

16

18

20

22

24

26

28

30

32

0

50

100

150

200

DWS-F (clod size: 9-19mm)

DWS-F (clod size: less than 2mm)

DWS-G (clod size: 2-19mm)

DWS-S (clod size: 2-19mm)

DWS-S (clod size: less than 2mm)

Ignition loss (%)

Elapsed time (d)

Figure 4. Changes of ignition loss of DWS at 30 deg. (Watanabe et

al., 2011).

desiccator

wireless CO

2

sensor

outlet of water

water

trap

burette

pore water pressure gauge

displacement gauge

load cell

airpressure gauge

distilled

water

hydro

peroxide

solution

porous stone

Figure 5. Apparatus for triaxial compression test.

Table 2. Decomposition rate of organic matter by 6% hydrogen

peroxide solution for 24 h.

Decomposition rate (%)

DWS

Fulvic acid

Humic acid

Humin and soil

particles

B

77.1

44.9

3.1

C

86.5

43.2

8.1

D

88.0

46.6

10.3

E

73.4

42.5

6.6