3268

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

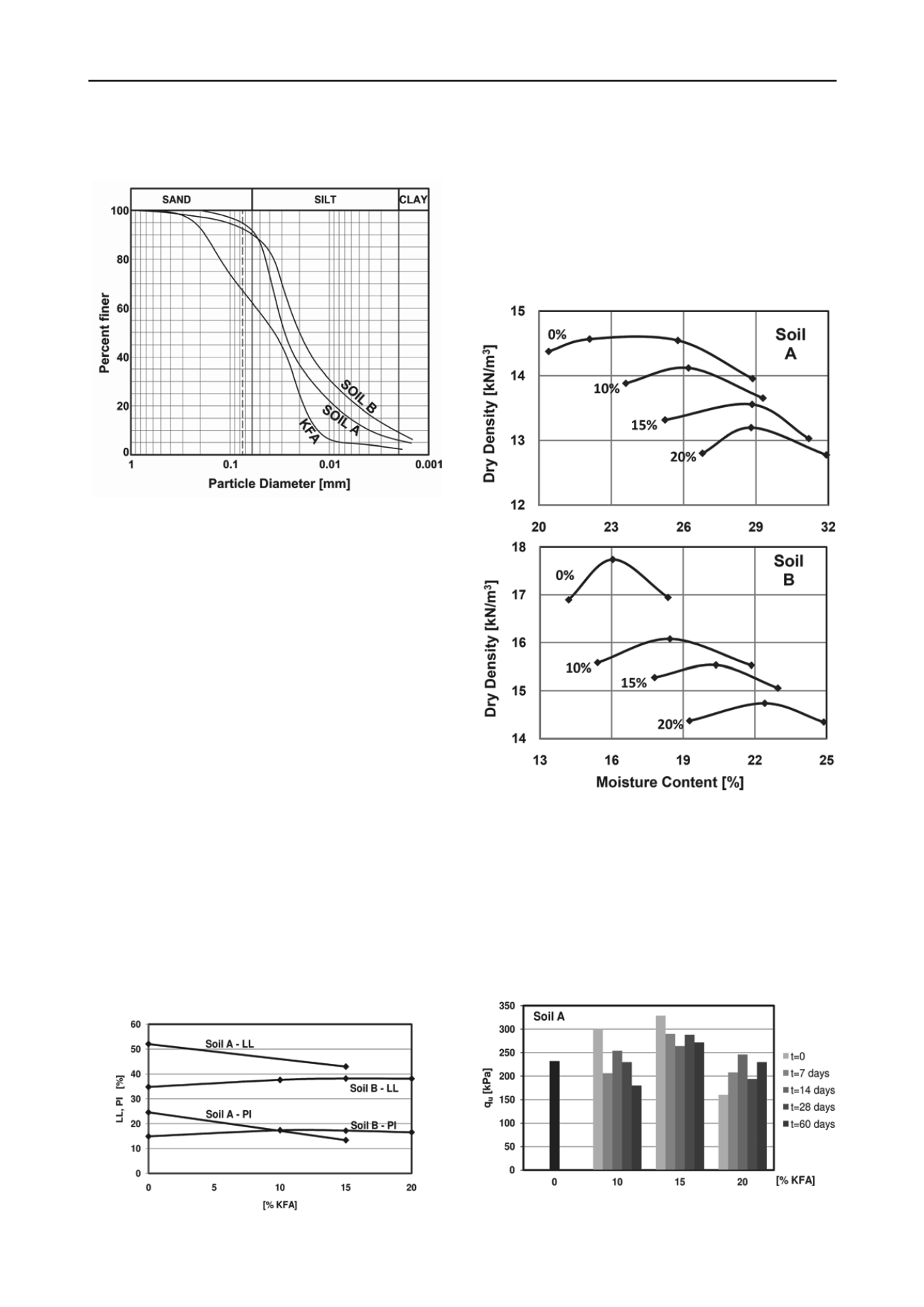

clay (CL). Grain size distribution curves for used materials are

given in Figure 1.

Figure 1. Grain size distribution curves

3

LABORATORY TESTING

Laboratory testing was conducted in the Laboratory for soil

mechanics at Faculty of Civil Engineering in Belgrade. Testing

samples were prepared by compaction, with moisture content

equal to optimum moisture content from standard Proctor

compaction test.

Fly ash soil mixtures were prepared at three fly ash-soil

ratios (10, 15, 20% fly ash content by dry weight). After

addition of water, mixtures were compacted without delay.

According to (Terrel et al. 1979, Ferguson and Leverson 1999)

compaction should start immediately after the mixing process

and finish within a maximum of 2 hours. Samples were tested

immediately after compaction (t=0), as well as after 7, 14, 28

and 60 days. Following engineering properties were determined:

unconfined compression strength (UCS), California bearing

ratio (CBR), effective shear strength parameters (c’,

’) and

compressibility modulus (M

v

). All tests were performed

according to SRPS Standards.

4

RESULTS AND DISCUSSION

4.1

Soil plasticity

In case of medium to high plasticity soil (soil A), it is observed

that increasing of KFA percentage results in decreases in the

liquid limit and plasticity index, which is not the case for low

plasticity soil (soil B), as shown in Fig. 2.

Figure 2. Variation in Atterberg limits for mixtures at t=0

4.2

Compaction

The results (Fig. 3) indicate that maximum dry density

decreases and optimum moisture content increases as the fly ash

content increases (for both soil types). The decrease in

maximum dry density is associated with the fact that used fly

ash has much lower weight than soil. Results are in line with

Santos et al. 2011 and Sharma 2012, while

opposite trend can

be found for Class C fly ash stabilization (White et al. 2005 and

Ramadas and Kumar 2012).

Figure 3. Moisture-density relationship of fly ash-soil mixtures

4.3

Unconfined Compressive Strength (UCS)

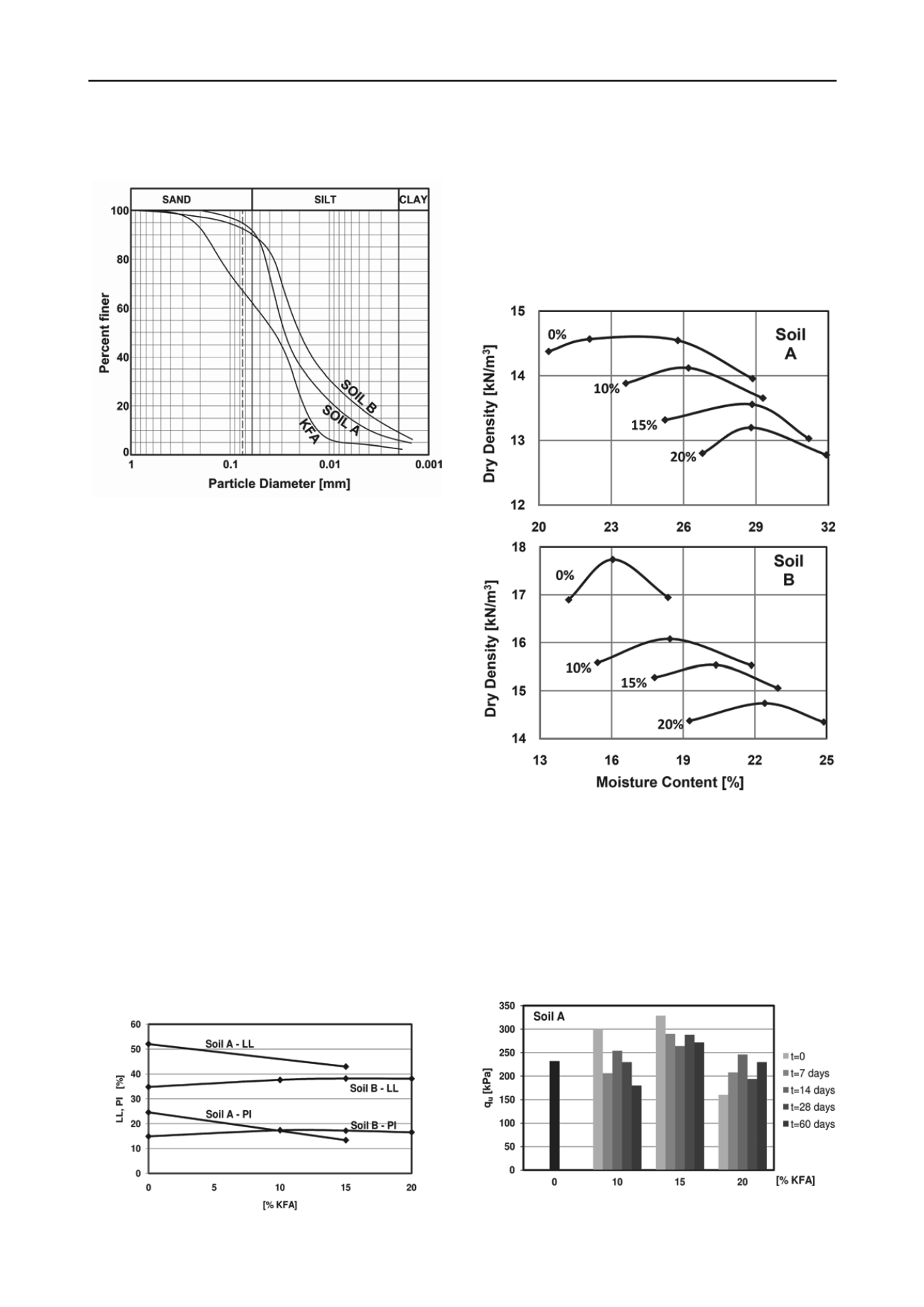

Increased soil strength is the main indicator of the successful

soil stabilization. In previous studies (Ferguson and Leverson

1999, Ferguson 1993, Parsons 2002, Edil et al. 2006) strength

of soil is usually determined by uniaxial compression test or

bearing ratio test. The results of UCS tests shown in Fig. 4

indicate that maximum strength gain for soil A is obtained for

mixture with 15% KFA. Soil UCS is increased by 15-25%,

dependent of elapsed time.

Figure 4. Strength gain of soil A for different percentages of KFA