3274

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

(2)

1 2

0

2

t

t D C M

e

D

e

of Al is 4.77

×

10

-15

m

2

/s which was obtained by the serial

batch leaching test (Watanabe et al., 2010). As

t

1

is 0, the Eq. 2

transforms to Eq. 3, and it relates the cumulative Al release

M

exp

obtained in the triaxial tests to the elapsed time

T

.

e

DC

M

T

2

0

2

exp

4

(3)

Therefore, the transition of the internal friction angle caused

by decomposing the mechanical bridging is calculated as shown

in Table 3. Approximate 1.3% decrease in the internal friction

angle supposedly causes during 38 years.

4.2 Shear strength transition addressing decomposition of

organic matter

The organic matter decomposition of DWS as a subgrade

material is able to be interpreted as following, assuming aerobic

and unsaturated condition. Jenny (1941) described the decrease

in soil organic matter as Eq. 4.

rX

dt

dX

(4)

where

X

is the mass of organic matter and

r

is the rate of

decomposition. A solution of Eq. 4 is given by Eq. 5.

rt

e X X

0

(5)

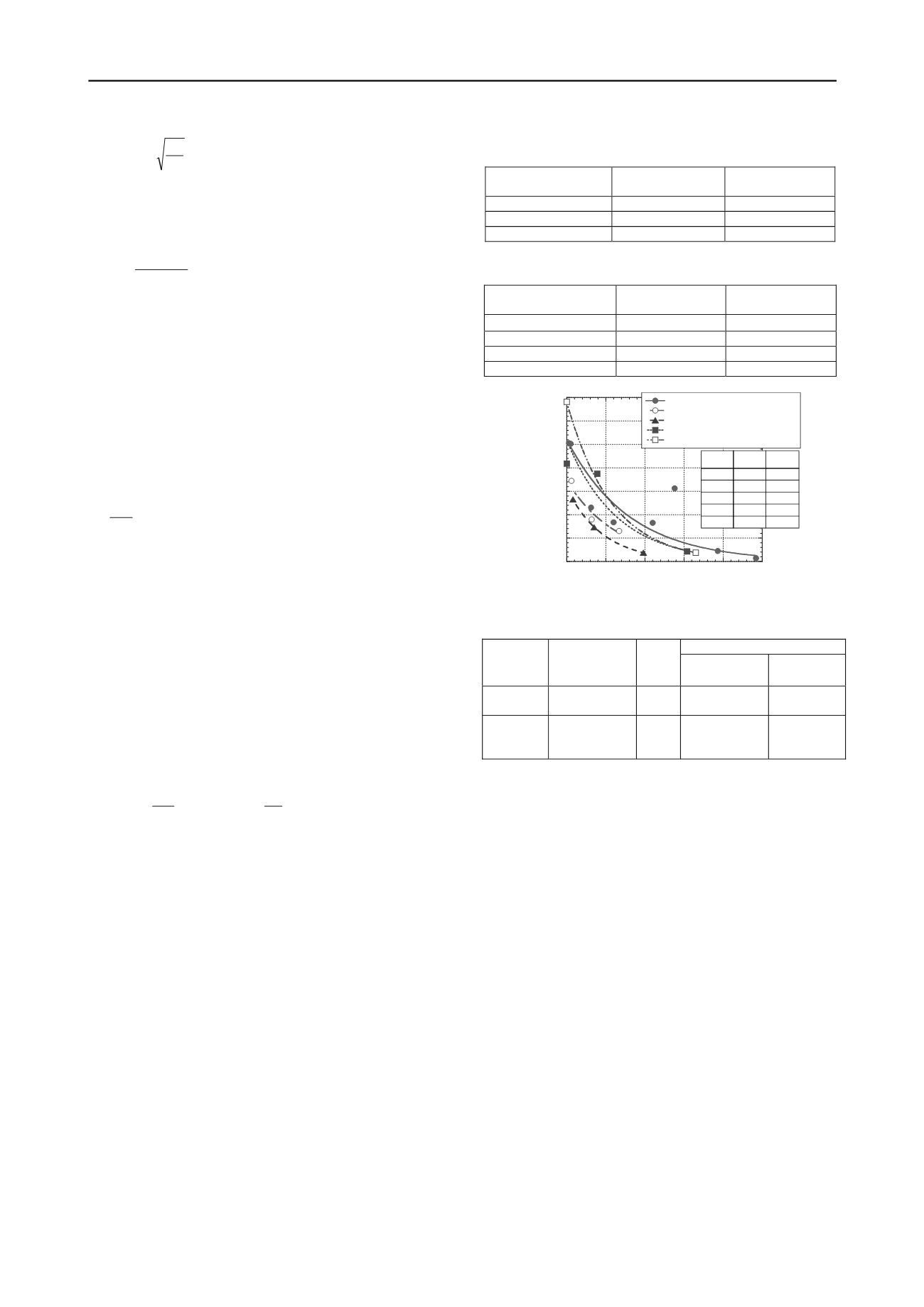

Assuming aerobic biodegradation, discharged CO

2

is

originated from the carbon loss of decomposed organic matter

approximately. From the results of constant temperature storage

in aerobic condition of DWS (Watanabe et al., 2011),

r

is

determined by fitting Eq. 5 into the experimental data as shown

in Fig. 8. The daily CO

2

discharge during organic matter

decomposition corresponds to the decomposition mass of

organic matter, so the time integral of Eq. 5 approximately

represents the total mass of decomposed organic matter

Q

dec

.

44

12

2

1

0

rt

et

dec

e

e

r

X Q

(6)

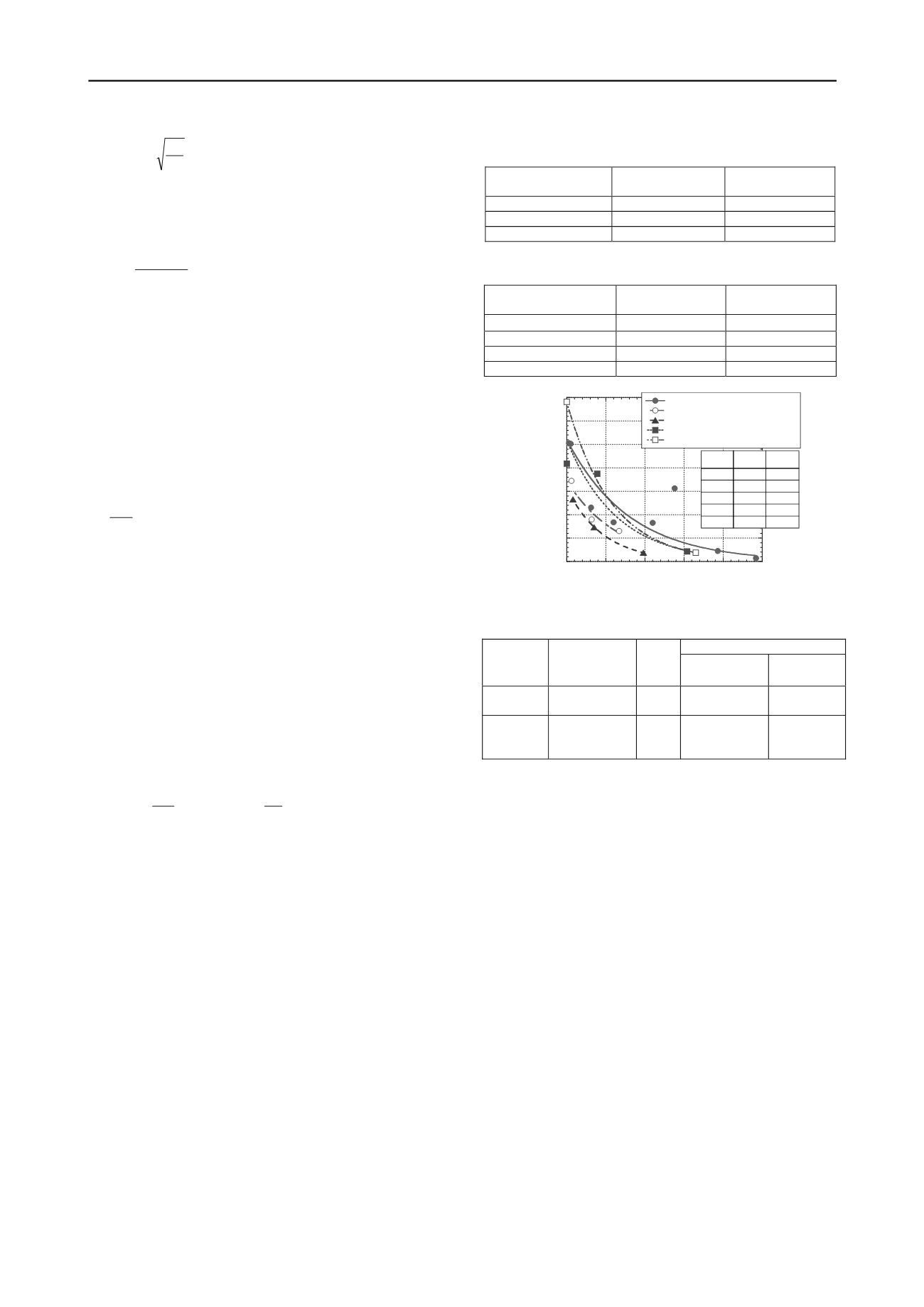

Calculation results for the transition of the internal friction

angle caused by decomposing the organic matter are listed in

Table 4. Approximate 3.1% decrease in the internal friction

angle by organic matter decomposition causes during 22 days in

aerobic condition. Assumption of aerobic condition is not

suitable for practice, so this study confirmed the organic matter

decomposition in site. In the experimental construction that

DWS was used as a backfill material of water pipe construction,

the DWS layer was taken a position of -0.4 to -0.9 m depth

under asphalt surface. The compaction degree was approximate

64

―

76%. The monitoring term was 19 months. As shown in

Table 5, ignition loss slightly decreased at the end of the

experiment. It is presumed that organic matter decomposition

slowly progressed in contrast to the constant temperature

storage because of anaerobic condition and lower temperature.

The proposed method with aerobic condition excessively

estimates the degradation in contrast of underground conditions.

5 CONCLUSIONS

DWS is the aggregation of clay and organic compounds.

Focusing on the chemical bonding by flocculating agent and

organic matter, a simplified method for the prediction of

changes in shear strength of DWS in geotechnical works was

proposed. The decomposition of the mechanical bridging and

the organic matter was described based on diffusion-controlled

Al leaching and aerobic biodegradation, respectively. The

methodology proposed in this paper is significant to encourage

safe geotechnical utilizations through estimations of the usable

term for not only DWS but also available waste or by-products.

Table 3. Shear strength transition addressing decomposing the

mechanical bridging.

Cumulative

Al release

(mg/kg)

Calculated

elapsed time (y)

Internal friction

angle (deg.)

0

0

37.2

0.130

17.4

37.6

0.192

38.0

36.7

Table 4. Shear strength transition addressing decomposing the

organic matter.

Decomposition rate of

organic matter (%)

Calculated

elapsed time (d)

Internal friction

angle (deg.)

0

0

38.8

0.14

2

39.2

0.79

12

38.5

1.38

22

37.6

0

500

1000

1500

2000

2500

3000

3500

0

50

100 150 200 250

1: DWS-F(clod size: 2 - 19mm)

2: DWS-F(clod size: less than 2 mm)

3: DWS-G(clod size: 2 - 19mm)

4: DWS-S (clod size: 2 - 19mm)

5: DWS-S (clod size: less than 2 mm)

Daily CO

2

discharge (mg/kg/d)

Elapsed time (d)

r

X

0

CASE

-0.0125

2607.1

1

-0.0155

1725.1

2

-0.0215

1563.9

3

-0.0157

2589.8

4

-0.0175

3408.0

5

Figure 8. Results of constant temperature storage in aerobic condition of DWS (Watanabe

et al., 2011).

Table 5. In-situ monitoring results of ignition loss of DWS

Ignition loss (%)

Compaction

degree

(%)

CBR

(%)

before

construction

19 months

later

Air-dried

DWS

75.9

38.1

16.9

16.6

Filter-

pressed

DWS

64.3

55.3

24.7

24.0

REFERENCES

1) Jenny, H. (1941):

Factors of soil formation

, McGraw-Hill, New

York.

2) Mitchell, J. K. and Soga, K. (2005):

Fundamentals of Soil

Behavior

, third edition, John Wiley & Sons, Inc.

3) Montgomery J. M. (1985):

Water Treatment Principles and Design

,

John Wiley & Sons Inc., pp.116-134.

4) Ohkubo, N., Yagi, O., and Okada, M.: Effects of humic and fulvic

acids on the growth of microcystis aeruginosa,

Environmental

Technology

, Vol. 19, pp. 611-617, 1998.

5) Roque, A. J. and Carvalho, M. (2006): Possibility of Using the

drinking water sludge as geotechnical material,

Proc. of 5

th

International Congress of Environmental Geotechnics

, pp.1535–

1542.

6) Watanabe, Y. et al. (2009): Environmental impact assessment of

drinking water sludge,

Journal of Japan Society of Civil

Engineering G

, Vol. 65, No. 3, pp. 188-201.

7) Watanabe, Y. et al. (2010): Serial Batch Leaching Test for

Evaluating Degradation of Drinking Water Sludge in Geotechnical

Reuse,

Proc. of 6

th

International Congress of Environmental

Geotechnics

, pp.1073-1078.

8) Watanabe, Y. et al. (2011): Composition and decomposition of

organic matter of drinking water sludge,

Proc. of 9

th

Geo-

Environmental Engineering

, pp. 435–438.