3285

Technical Committee 210 + 201 /

Comité technique 210 + 201

For high ECRD, the seepage stability of gravelly soil

depends on many factors. Besides gradation, dry density, stress

level and downstream protection are all have impacts on the

internal stability of soil upon seepage flow. Normally, the

mixture of sand, gravel and fine grains with good gradation will

present good erosion resistance. For gravelly soil, if the content

of coarse grains (>5mm) below 50%, the content of clay grains

(<0.075mm) above 15%, and the material is well compacted,

the gradient for resisting seepage failure will be relatively high.

But in practice it should be aware that due to the variability of

gravelly soil, the result obtained by calculation must be checked

by filter test.

3.1.3 Rockfill material

Rockfill is the main construction material of rockfill dam. Its

strength properties are related with dam slope stability and its

stress-strain properties are related with dam deformation. From

the experience of modern rockfill dam construction,

deformation control is the most important issue to be

considered. For high rockfill dam, rockfill with high or medium

rock strength, i.e. the saturated uniaxial compressive strength is

30

∼

80MPa, should be the best choice. For getting high

compaction density, the rockfill should also have good

gradation. From the point of deformation control and

deformation coordination, rockfill for CFRD should have as

high compaction density as possible. The purpose is to reduce

the overall deformation quantities. For ECRD, the consideration

in rockfill selection is more emphasized on deformation

coordination between dam shell and earth core.

The particle shapes of rockfill material are usually

polyhedron. Most of the particles are contacted by point. The

compressibility of rockfill mainly depends on re-arrangement of

particles, and it is also affected by other factors such as rock

lithology, density, gradation, etc. Due to the granular

characteristic of rockfill material, grain breakage and particles

rearrangement is occurred at any moment during loading

process. That means the status of rockfill material will be

changed all the time. Therefore, the material properties will not

be a constant value. For low dam, as the relatively low stress

level of rockfill, the breakage of particles is not significant and

most of the deformations are occurred during the stage of

compaction. For high dam, due to the high stress level and

complicated stress paths, the breakage and rearrangement of

particles cannot be neglected. The process of the particles

breakage and particles movement will lead to a significant

increase of the post-construction deformation of rockfill. At

present, this post-construction deformation of rockfill cannot be

fully analyzed by existing models and methods. For correctly

describe the change of status of rockfill material that caused by

particles breakage and rearrangement, the properties of particles

breakage of rockfill material must be fullly studied, and the new

analysis models will be further developed.

For rockfill, another important characteristic is the wetting

deformation property of the material. The mechanism of wetting

deformation of rockfill is the inteneration and breakage of the

edge of rockfill particles under the action of water. Besides, the

lubricating action of water promotes the movement and

rearrangement of the particles. Thus, it leads to the additional

deformation. The wetting deformation of rockfill is directly

related with its lithology. Normally, soft rockfill has relatively

large wetting deformation. But it is noticed that even for the

hard rockfill, such as limestone and tuff, the wetting

deformation still cannot be neglected. The wetting deformation

of rockfill will be reduced with the increasing of its density. In

addition, the more of initial water content of rockfill, the less

wetting deformation. Therefore, adding water during rockfill

compaction will play an important role in speed up deformation

completion and reducing post-construction of rockfill.

Correctly predict deformation of rockfill dam depends on the

constitutive model used in numerical analysis. The paper

submitted by Y. Chen used an elasto-plastic model that takes

into account irreversible deformations of poorly or well-

compacted rockfill under deviatoric and isotropic loading of

rockfill, known as L&K-Enroch, developed by EDF-CIH (Chen

2013) to conduct 3D numerical analysis of Mohale CFRD in

South Africa.

3.2 Foundation treatment

Foundation or subsoil condition is very important to the safety

of dam. Before the construction of dam, the unfavorable layer in

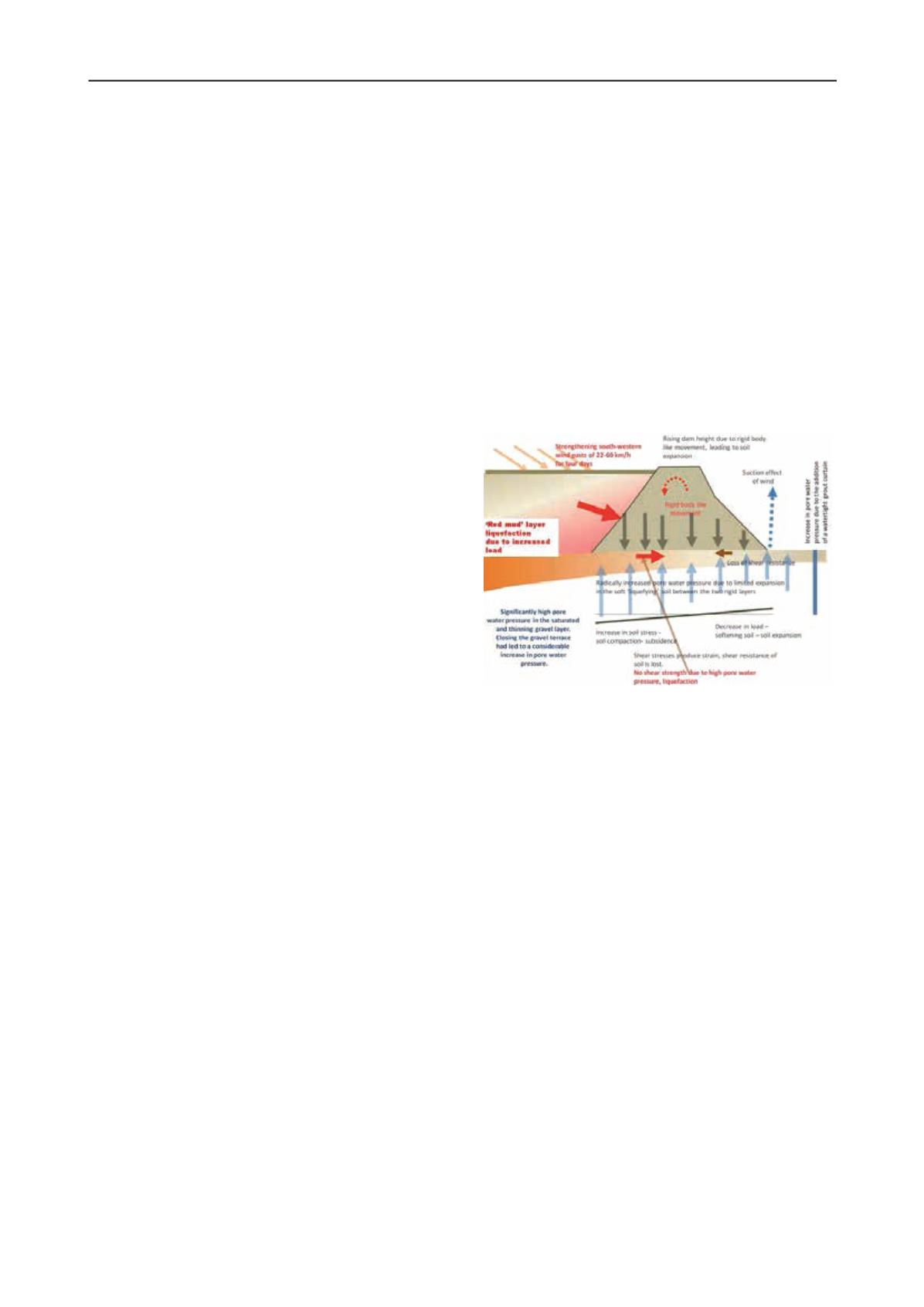

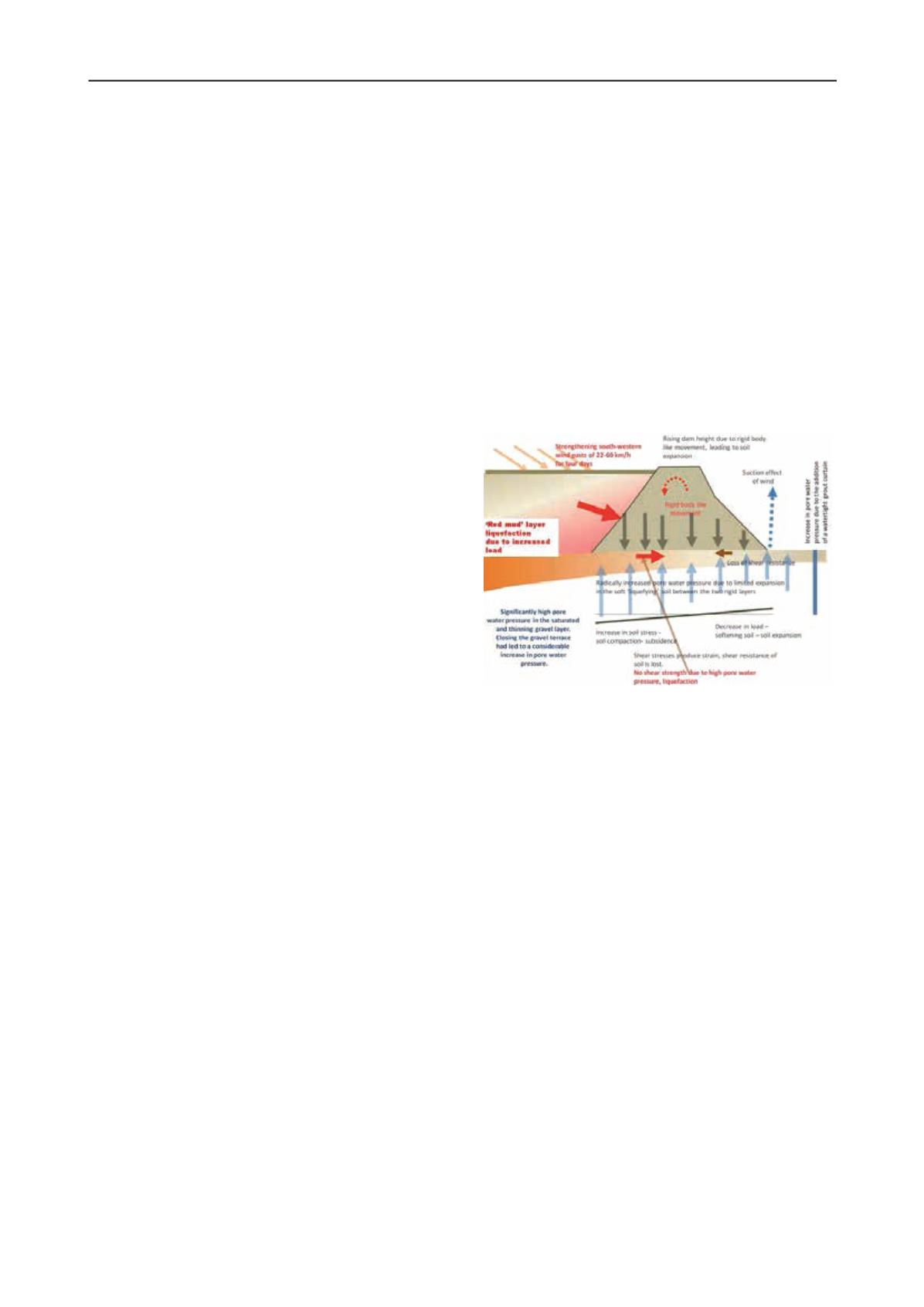

foundation must be properly treated. The paper submitted by J.

Mecsi presented a failure case of tailing dam in Hungary (Mecsi

2013). The foundation of the dam has a sand-silt layer that may

move under high water condition. Figure 4 is the summary of

some effects for the failure of the tailing dam. It shows the

impact of the unfavorable subsoil on the safety of the dam.

Figure 4 Summary of the effects for tailing dam failure

The foundation of high rockfill dam includes bedrock

foundation and alluvium foundation of sandy gravel deposit.

For the sandy gravel alluvium, if the alluvium has no soft, weak

clay layers or silt, fine sand layers, the bearing capacity and

stability of the foundation can be guaranteed. The main task of

foundation treatment is seepage control. If the lower part of

alluvium foundation exist sand layer, the possibility of sand

layer liquefaction should be carefully assessed.

For high rockfill dams, the commonly accepted seepage

control measure for foundation treatment is vertical cut off. It

could effectively block the seepage though pervious alluvium

foundation. With the measures of filter and drainage at

downstream seepage exit, the foundation and dam body will not

subject to seepage failure.

For high rockfill dam with deep alluvium foundation, the

most effective vertical seepage control measures are excavation

of all the alluvium layers under the impervious part of the dam

or using concrete diaphragm wall to cut the seepage though

foundation. Recently, concrete diaphragm wall is accepted for

most of the high CFRD constructed on deep alluvium

foundation. For this application, the diaphragm wall is

connected with plinth via concrete slabs (Xu 2010). For high

ECRD, both measures as alluvium excavation and concrete

diaphragm wall are applied.