3283

Technical Committee 210 + 201 /

Comité technique 210 + 201

seepage pressure in advance for keeping the stability of

foundation and geotechnical structure. (3) Prevent seepage

failure of foundation and structure. Generally, the

corresponding engineering measures are also includes three

aspects:

·Seepage prevention: Put impermeable material in dike and

foundation to cut the seepage passage and to decrease the water

head in the dike and foundation.

·Drainage: Put permeable material as drainage at the certain

places in the dike and foundation where the hydraulic gradient

is relative large. To release the seepage pressure and let the

seepage water freely discharge to downstream by the drainage.

·Filter protection: Filter is an effective measure for preventing

seepage failure of soil. As it also has the drainage function, it is

often as one part of the drainage. The materials for filter are

natural sand and rock. But the material must satisfy following

principals:

�

filter material must be non-piping soil.

�

the

gradation relation between filter and protected soil must satisfy

filter principals.

�

the permeability coefficient of filter must

larger than the protected soil.

�

the coarse grains of the filter

must hard and weathering resistant.

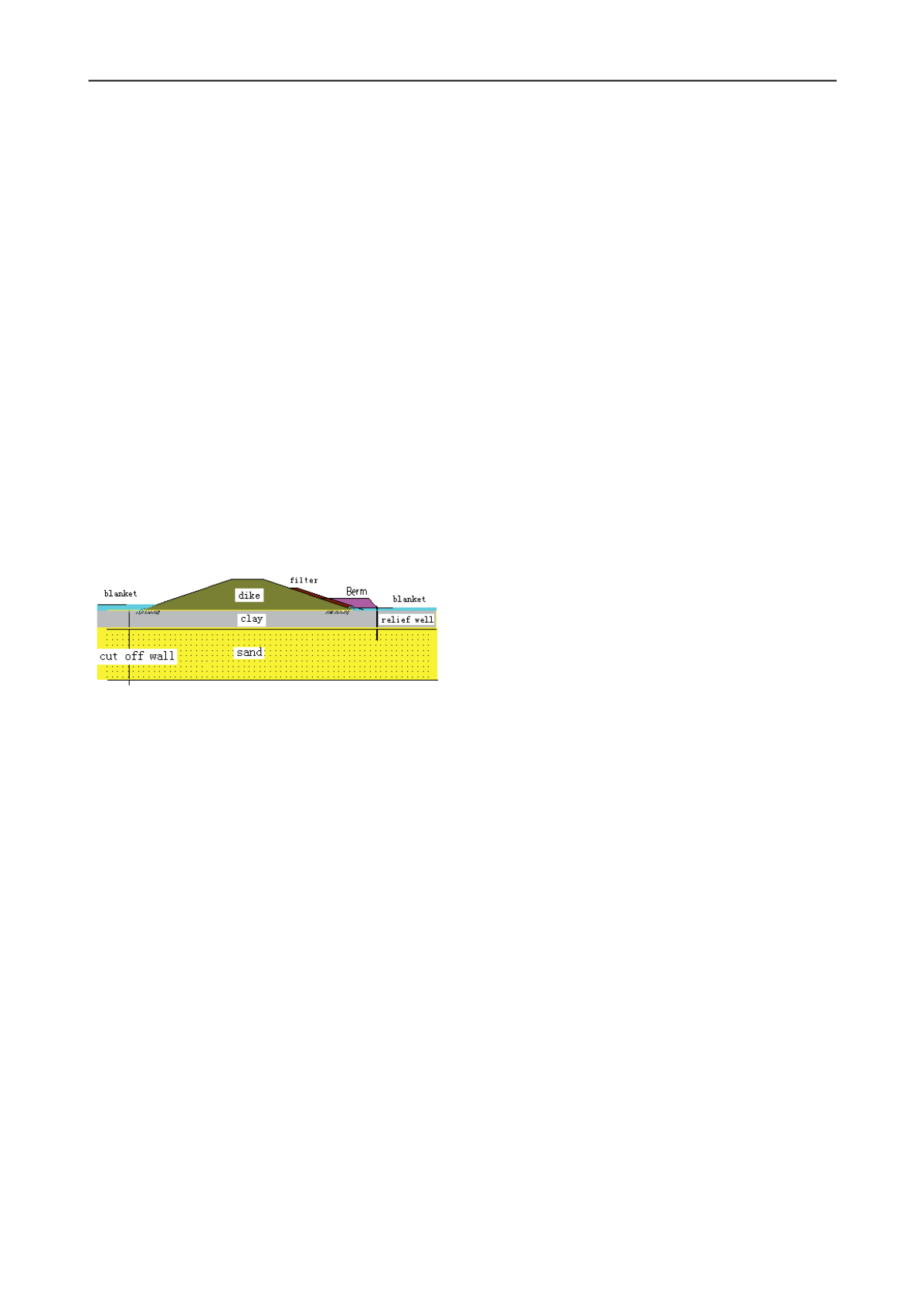

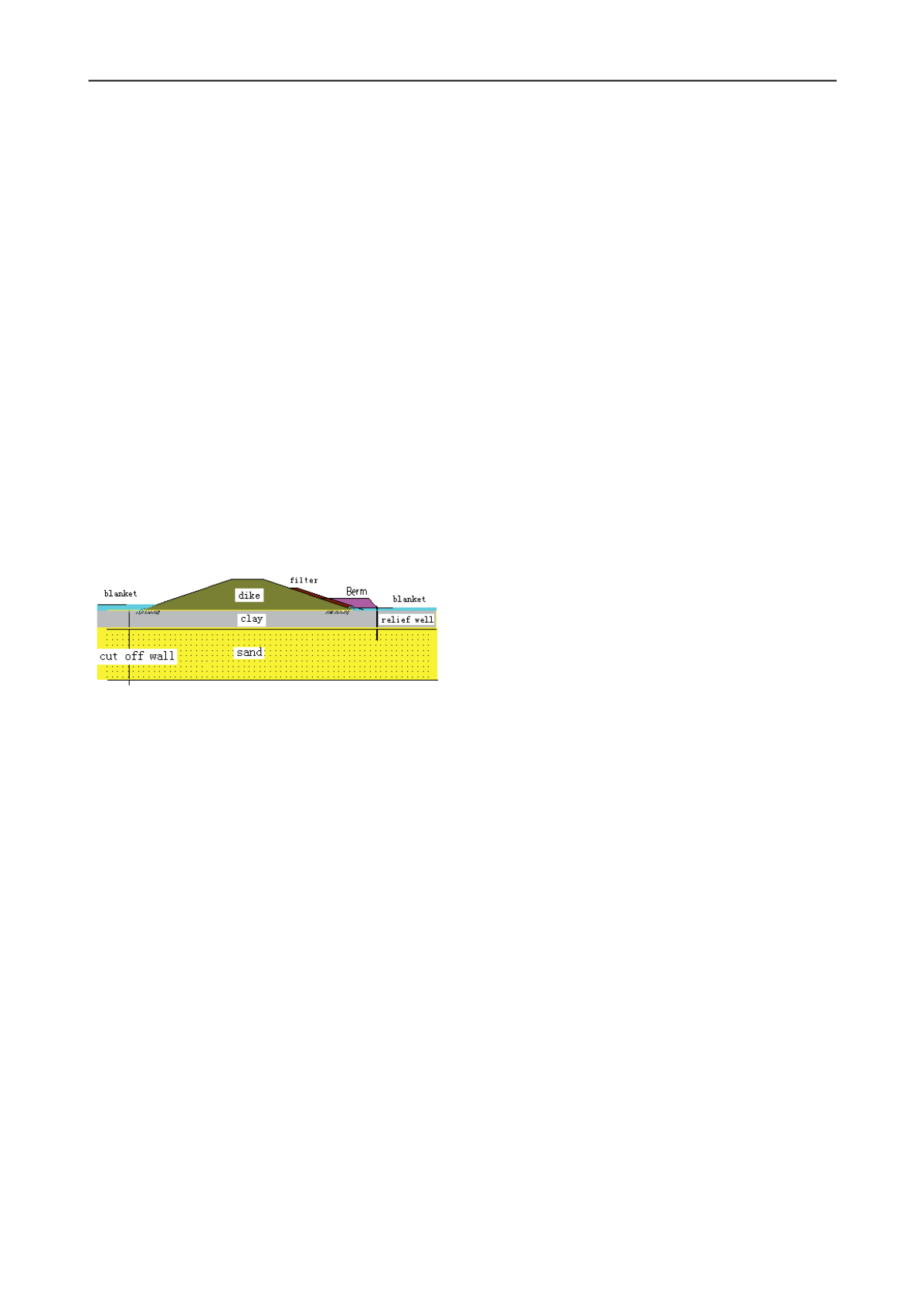

Figure 2 gives the typical engineering measures of seepage

control applied in dike construction. The selection of theses

engineering measures depends on the different situations of the

dike.

Figure2 Engineering measures of seepage control

2.3 Bank collapse

In nature rivers, the interaction of water flow and riverbank

(upstream slope of dike) could cause bank erosion and bank

collapse, which are the common damage to the safety of dikes.

In USA, the total length of river channel is 5,600,000 km.

About 800,000km riverbank were suffered of flow erosion,

include bank collapse. In China, a severe bank collapse case

has caused the lost of 115,000m

3

land. About half of a town was

collapsed into river.

There are many factors that affect the occurrence of bank

collapse, which include hydraulic features, properties of the

materials of riverbed and river bank, features of river bank,

impact of wind and wave, impacts of climate, impacts of human

activities, etc. (Simons, 1982). For all these factors, water flow

and boundary are the basic conditions.

For the mechanism of bank collapse, there are different

viewpoints. Some scholars think water flow is the precondition

of bank collapse. When the main stream of river approach

riverbank, water flow will scour the bank and the bank slope

will be steep. Some scholars believe the liquefaction of soil the

cause of bank collapse. According to the force act on soil, the

liquefaction of soil could be classified to shear liquefaction,

seepage liquefaction and vibration liquefaction. If the dike is

composed by non-cohesive sand or soils with less cohesion, its

effective stress may drop to zero under the action of shear stress

or seepage force. Some scholars explain the mechanism of bank

collapse from the point of slope stability. Bank collapse

occurred when upstream slope of the dike lost its stability. In

flood season, soil of dike is submerged in water, which lead to

the reduction of its shear strength. With the drop of upstream

water level, the seepage force towards riverside and the reduced

c,

ϕ

value could cause riverbank lost the stability.

As bank collapse is the result of the interaction of river flow

and watercourse boundary condition, the engineering measures

for avoiding bank collapse will mainly focus on water flow and

watercourse boundary. For changing local water flow, groyne

works are commonly employed. For improving boundary

conditions, different bank protection method could be applied,

which include riprap, concrete protection, geosynthetics, etc.

3 GEOTECHNICAL PROBLEMS OF ROCKFILL DAM

Rockfill dam is a widely applied dam type of dam engineering.

The development of earth core rockfill dam in 1940s to 1960s is

mainly based on the progress of the theory of soil mechanics. In

recent years, more and more high rockfill dam will be

constructed. New challenges on geotechnical engineering

problems are encountered in the construction of those high

dams.

3.1 Construction material

The construction materials of rockfill dam include impervious

material, filter/transition material, and rockfill material. Proper

application of the construction material according to its

engineering properties is one of the key issues for rockfill dam

design.

3.1.1 Impervious material of earth core

For high ECRD, earth core will subject to high stresses.

Ordinary clay material could not meet the strength and

compressibility requirements of high dam. Therefore, for most

ECRD with the height above 200m, the core material uses

gravelly soil. As for the composition, gravelly soil is mixture of

clay and gravels with the grain size larger than 5mm (or 2mm).

Soil of weathered rock and glacier deposit are also a kind of

gravelly soil.

(1) Gradation adjustment for gravelly soil of core material

Generally, if the soil has more than 20% coarse grains content,

i.e. the grain size larger than 5mm, it could be classified as

gravelly soil. Those soils include various soils with gravels, clay

gravel and weathered rocks.

The composition of nature formed gravelly soil is very

inhomogeneous. When it is used as core material, its gradation

and water content are often need to be adjusted by the

requirement of design.

For nature gravelly soil with wide range of gradation, if the

material is basically applicable, the oversize particles could be

removed to increase the content of fine particles. The case for

applying this measure is Pubugu ECRD in China.

The impervious material for the central core of Pubugou

ECRD is the gravelly soil with wide range of gradation. The

coarse grain content is 50%

∼

65% and the content of particles

with the size less than 0.1mm is 8.8

∼

20%. In soil classification,

the material is GP. The permeability of the material after

compaction is 10

-4

∼

10

-5

cm/s, which is not fit the requirement of

impervious material of high dam. With series studies, two

measures were employed for improving the properties of the

material, which are: adjust gradation by removing the particles

with the size larger than 80mm (or 60mm) and use modified

Proctor compaction energy to increase its density.

After removing the particles of the size larger than 80mm

form the nature wide range gradation gravelly soil, the gradation

of the material was improved significantly. The content of

particles of the size less than 5mm was 50%, and the content of

particles of the size less than 0.1mm was 22%. Classification of

the material was change from GP to GC. Permeability of the

material reached to 10

-5

∼

10

-6

cm/s. With the protection of filter

material, the hydraulic gradient of seepage failure was 60

∼

100.