3284

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

By using heavy compaction standard (modified Proctor

compaction), the compaction energy is increased from 604kJ/m

3

to 2704kJ/m

3

. Accordingly, the maximum dry density of the

material is increased from 2.23

∼

2.32g/cm

3

to 2.375g/cm

3

. The

permeability of the material is less than 1

×

10

-5

cm/s and the

deformation modulus is also remarkably increased.

For borrow soil mainly composed by fine grains, the material

usually cannot fit the stability and deformation requirement of

high dam. In this case, gravels or crushed rock should be added

to increase the content of coarse grains. The case for applying

this measure is Nuozhadu ECRD in China.

The borrow materials of Nuozhadu ECRD is mixture of

slope washed, residual soil and some strongly weathered rocks.

The average grain composition is: 24% gravels with the size

larger than 5mm, 44.3% fine grains with the size smaller than

0.074mm, 21.7% of the grains with the size smaller than

0.005mm. Most of the soils are classified as clay sand, low

liquid limit clay with sand. As most of the grains are weathered

sandstone and mudstone, grain particles are easily broken. After

compaction, the content of grins with the size larger than 5mm

could be reduced to 10%. The density, deformation parameters

and shear strength of the material are very low. Thus, it is

decided to add crushed hard rock to the nature borrow material.

The size range of crushed rock to be added in borrow

material is 5

∼

60mm. After optimization, proportion of the

adding material is 35%. From the research results, after adding

coarse particles, content of the grains with size larger than 5mm

is 50%, content of the grains with size smaller than 0.074mm is

23.6%, content of the grains with size smaller than 0.005mm is

10%. The classification of the mixed material is GC. It is an

idea impervious soil for high ECRD. Due to the breakage after

compaction, the content of grains larger than 5mm could be

36%. Compare with the unmixed material, the maximum dry

density could be increased from 1.7

∼

1.8g/m

3

to 1.9

∼

2.0g/m

3

.

The corresponding water content is about 10%

∼

15%. The

overall engineering properties of the material are greatly

improved.

(2) Gradation and permeability of gravelly soil

The permeability of gravelly soil has close relationship with its

gradation. For high ECRD, the general requirement is: the

content of grains with size larger than 5mm should not above

50% (or should below 60%), the content of grains with size

smaller than 0.075mm should not below 15%, and the content

of clay grains should not below 8%. But in practices, due to the

wide range gradation of natural gravelly soil, the above

principles could be adjusted according to the real situations. By

the analysis from the point of geotechnical engineering, the

requirement of content of grains with size larger than 5mm

should not above 50% is to guarantee the void of coarse grains

could be filled by fine grains. The requirement of content of

grains with size smaller than 0.075mm should not below 15% is

to guarantee the low permeability and to keep internal stability

of soil structure under seepage flow. As for the requirement of

the permeability of impervious soil, when it is in the quantity of

10

-5

cm/s, the actually leakage is quite small. It is unnecessary to

request the permeability to be 1

×

10

-5

cm/s. As for the seepage

stability, normally, the gravelly soil with wide range gradation

will have less clay grains. Thus, it has the same properties in

seepage deformation as non-cohesive soil. The hydraulic

gradient for seepage failure resistance of gravelly soil is mainly

depends on the filter at the exit. With the protection of filter, the

failure gradient can be improved significantly. Therefore, the

content of clay grains above 8% could not be an unchangeable

rule. For the case of Pubugou ECRD, the material has

17%

∼

48% grains with the size smaller than 1mm and 4%

∼

12%

clay grains. Under normal compaction, the tested maximum

hydraulic gradient could reach 90

∼

140.

(3) Compaction of gravelly soil

The two methods for soil compaction quality control are dry

density and compaction degree. In compaction, gravelly soil

presents the properties of both gravel and clay. For the

compaction of gravelly soil, it is required to get the maximum

dry density of the full material and also to check the dry density

of fine grains. By considering the variability of the soil,

compaction degree is more often to be used as the index for

quality control of gravelly soil compaction.

For the mixed soil with coarse and fine grains, besides the

compaction degree of full material, it is also has the compaction

degree of fine grins. As the compaction degree of fine grains

mainly controlled the permeability and mechanical property of

gravelly soil, it is unnecessary to conduct difficult large-scale

compaction test for full material. When content of coarse grains

is below 60%

∼

70%, the dry density of full material will be

increased with the increasing of coarse grains content. When

content of fine grains is below 20%

∼

30%, the coarse grains will

not take the function of soil skeleton. The fine grains are fully

compacted. Its dry density keeps unchanged. When content of

fine grains reaches 30%, the coarse grains start to take function

of skeleton. The more content of coarse grains, the stronger is

its skeleton function. Thus, the fine grains inside void cannot be

fully compacted. The dry density of soil will be reduced with

the increase of coarse grains. When content of coarse grains is

60%

∼

70%, the skeleton function of coarse grain is fully

realized. The dry density of full material and fine grains reduced

synchronously. All its mechanical properties are dropped in big

scope and the permeability of soil are increased rapidly.

Therefore, in the application of compaction degree control of

fine grains, when content of coarse grains is below 25%, the

compaction degree for fine grains could be controlled with

100%; when content of coarse grains is 25%

∼

50%, the

compaction degree control for fine grains could be reduced to

97%

∼

98%.

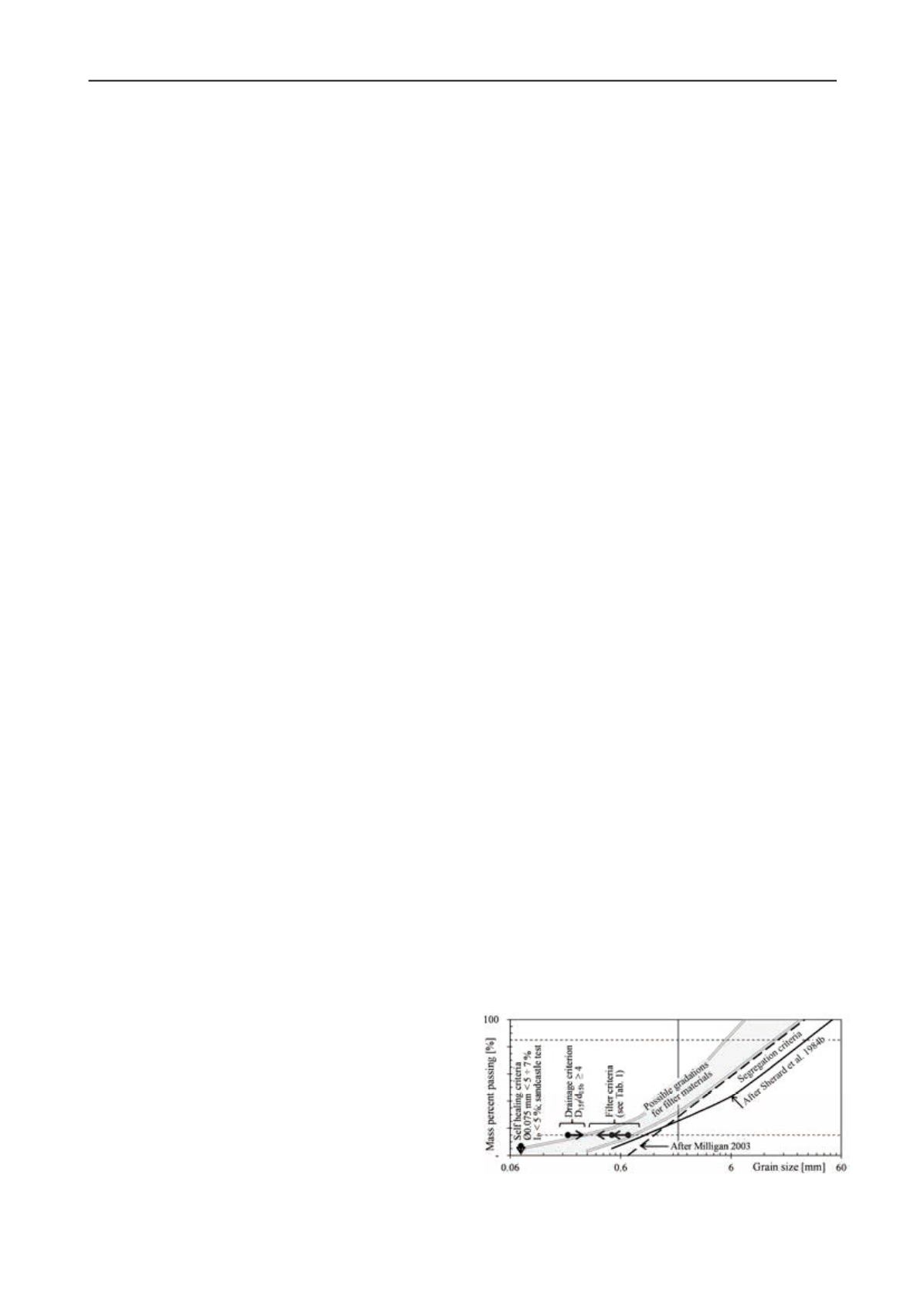

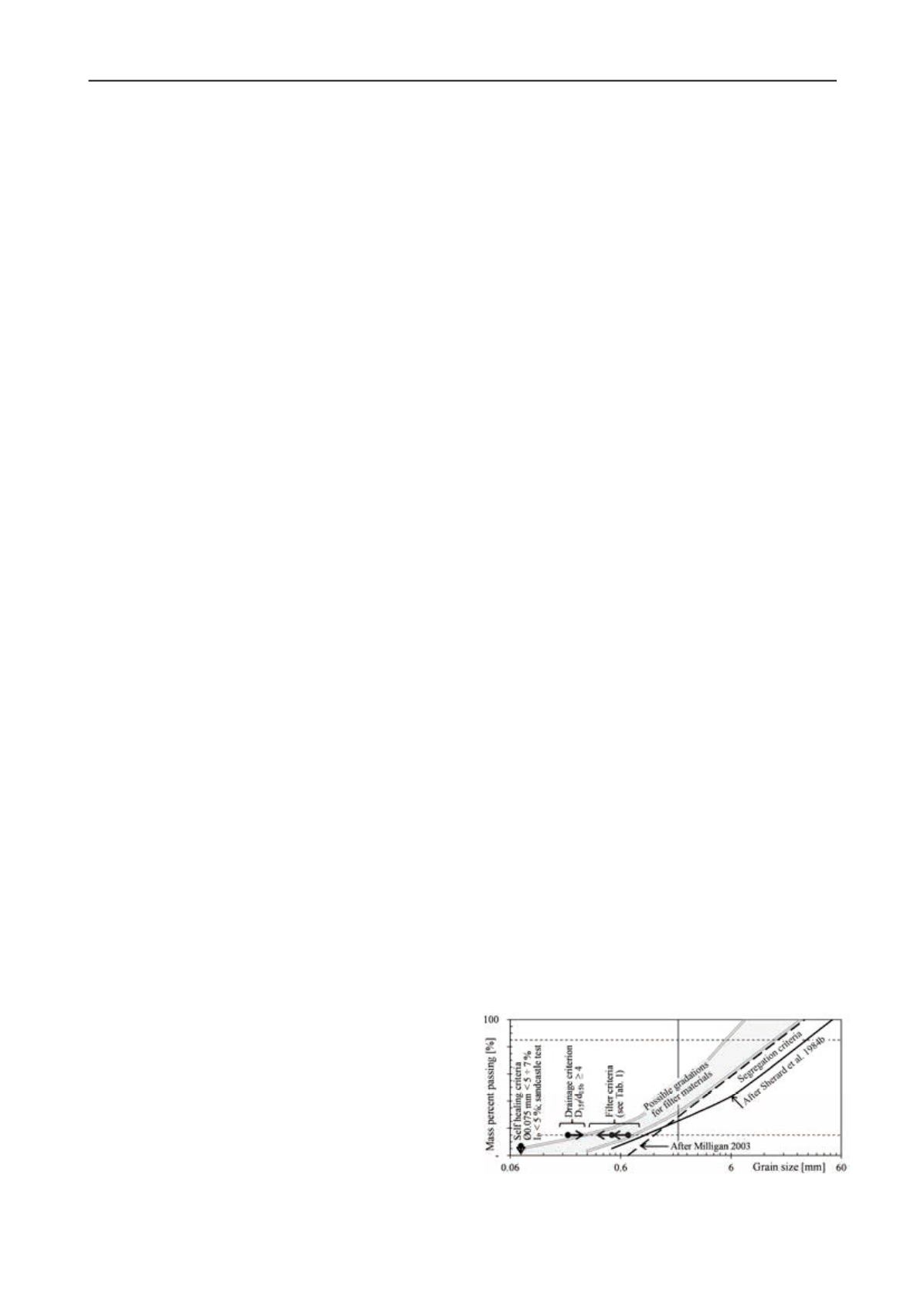

3.1.2 Filter material

The process of seepage failure in soil is always started from

exit, and gradually developed to the inside, then finally lead to

local failure or whole structure failure. Using filter to control

seepage exit is an effective seepage control measures in dam

engineering. It could be a drainage zone and also to prevent fine

grains flow out. For high ECRD with gravely soil as the core,

although gravelly soils have certain content of clay grains, it is

still belong to the soil without plasticity or with low plasticity.

The filter design should also follow the principle of no fine

grains been washed out. The paper submitted by S.

Messerklinger discussed the functions of filter in geotechnical

structures and summarized the main principles of filter design.

Figure 3 is the summary of the design criteria of filter design

(Messerklinger 2013). The paper submitted by R. Eerzariol

presented the test studies on filter protection of loess, a kind of

sandy silt that largely distributed in central Argentina. The

studies suggested that filter with fines content between 15% and

25% perform the best condition of seepage stability for

protecting silt core (Eerzariol 2013).

Figure 3 Design criteria of filter (Messerklinger 2013)