3265

Technical Committee 307 /

Comité technique 307

when subjected to drying, its use is not recommended for base

pavements, and some of the worst soil for the purpose of

paving, from the tropical soils (Nogami & Villibor 1995).

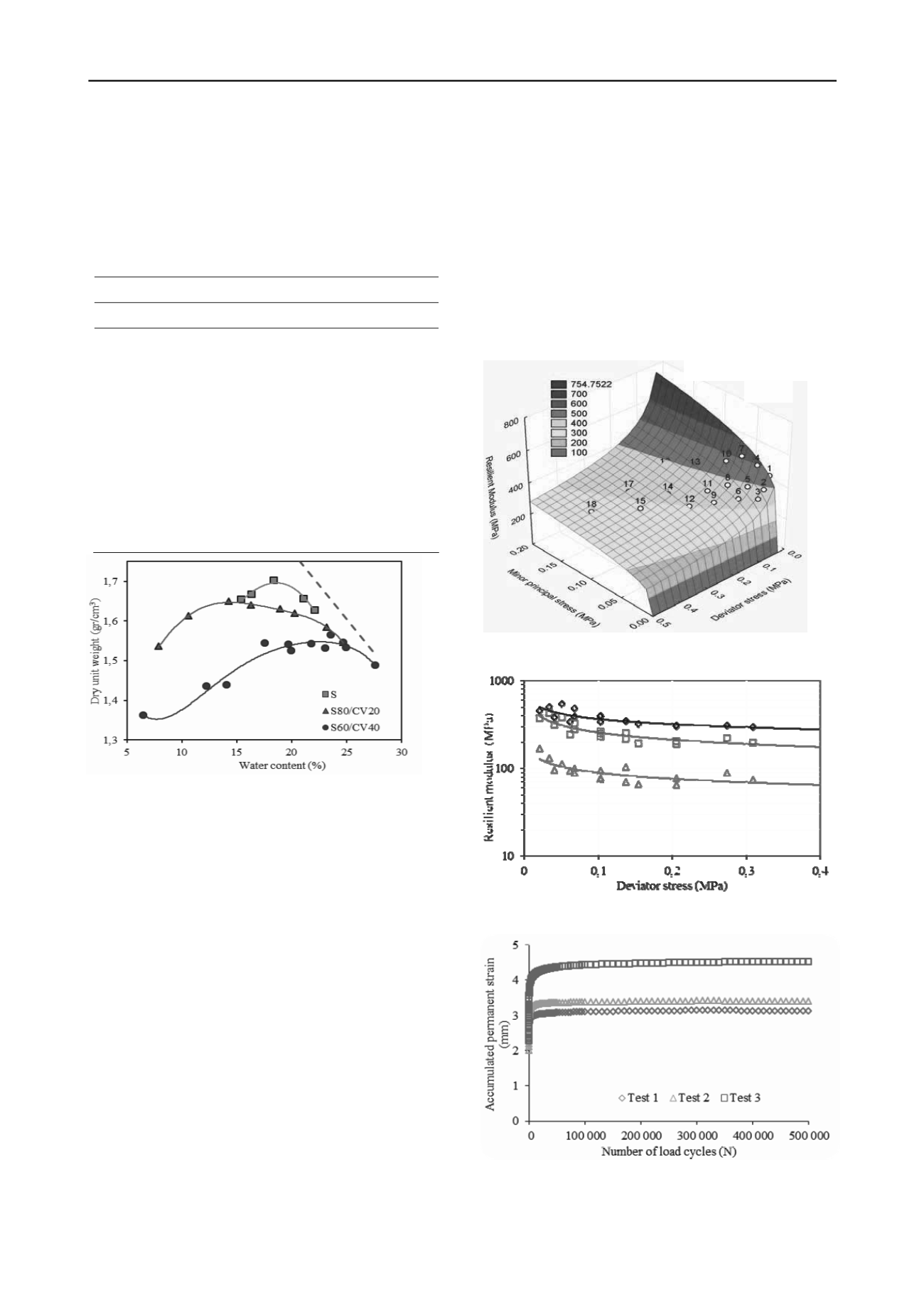

From the curves of soil compaction and mixtures with fly

ash obtained from the Modified Proctor tests, it can be stated

that by increasing the level of ash in the mixture, the maximum

dry density tends to decrease (Figure 2).

Table 3. Soil, MSW fly ash chemical composition

Concentration (%)

Compost

Soil

MSW Fly Ash

SiO

2

36 - 43

13 - 21

Al

2

O

3

35 - 38

12 - 15

Fe

2

O

3

13 - 21

5 - 7

SO

3

0 - 1

5 - 10

CaO

-

32 - 45

TiO

2

0,9 - 1,7

3 - 4

K

2

O

2 - 4

2 - 4

Cl

-

4 - 6

Organic Matter

0,1

0,7

Figure 2. Compaction Curves of Soil and 20% - 40% Soil – Fly Ash

Mixtures

4.3 Effect of MSW fly ash addition on resilient modulus

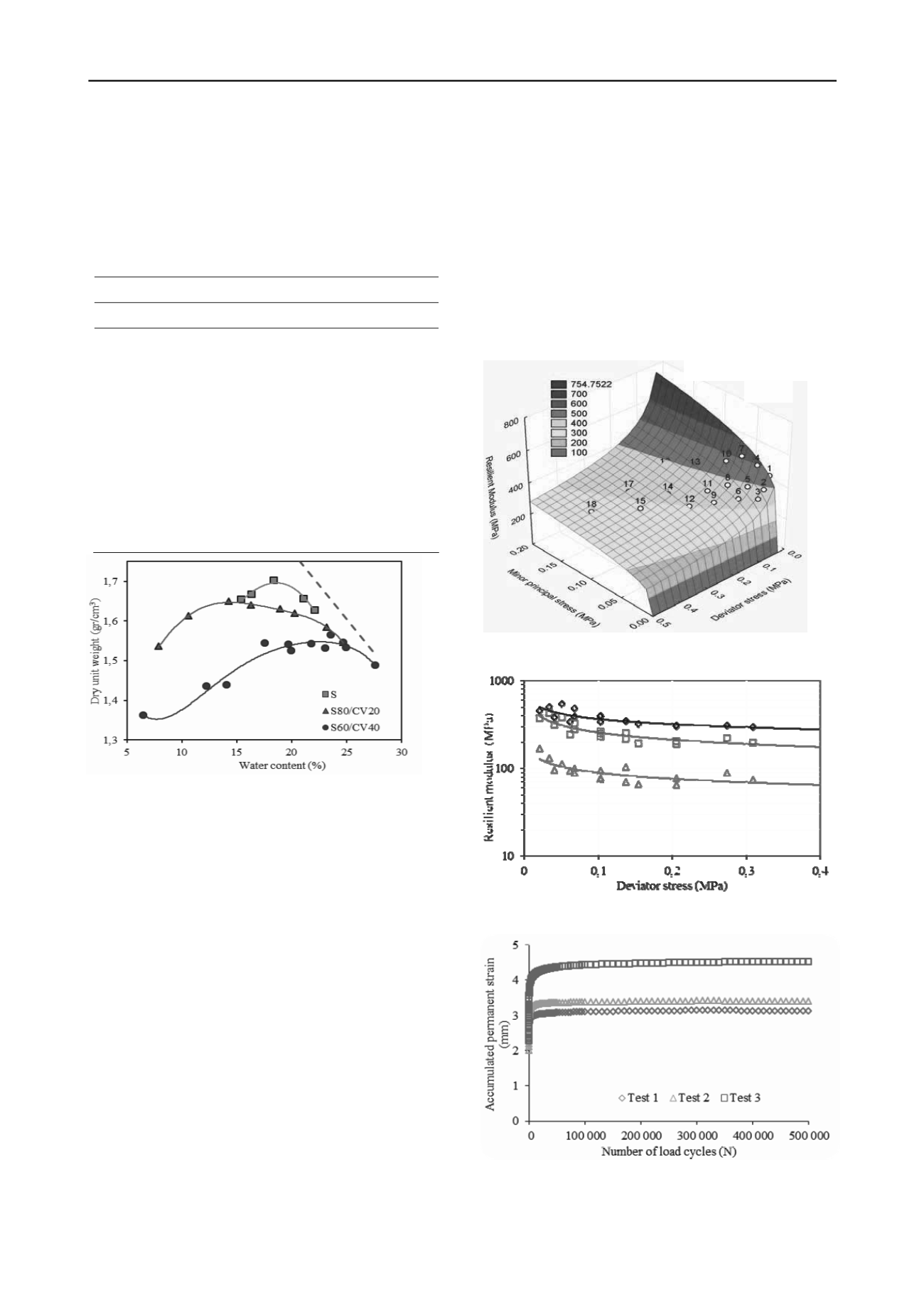

The results of Resilient Modulus tests (Figure 3) show that the

Resilient Modulus of soil in study is dependent on the deviator

stress and if the MSW fly ash is added, this behavior does not

change. It is appreciated that the higher the deviator stress, the

lower the value of resilient modulus.

The mixture with 20% MSW fly ash improved the

mechanical behavior of pure soil, the mixture with 40% MSW

fly ash downgraded the mechanical behavior, but it improved

with cure time (Figure 4).

The mixture with 20% MSW fly ash was assessed with

several different water contents. The results indicated the

resilient modulus increased as the water content decreased.

4.4 Effect of MSW fly ash addition on permanent

deformation

As shown in the Figure 5, the permanent deformation tends to

stabilize reaching a plateau, it´s observed that Test 3 has a

higher permanent deformation, this is due to increased tensions

applied to the test.

The resilient modulus is increased with the number of load

cycles (Figure 6), this can be explained by the diminution of

elastic strain. The occurrence of the plastic accommodation (i.e.

Shakedown) was investigated by using the behavior model

developed by Dawson and Wellner, cited by Werkmeister

(2003). The test results of permanent deformation test for the

MSW fly ash – soil mixture were obtained and are displayed by

the graph model of Dawson and Wellner cited by Werkmeister

(2003) in Figure 7.

By analysis of this Figure it appears that all tests conducted

with the MSW fly ash – soil mixture show a typical behavior

for level A, i.e., demonstrated plastic accommodation,

depending on the model proposed by Werkmeister (2003). The

characterization of the level A behavior of both the shape of the

curve, roughly parallel to the vertical axis, because when the

rate of permanent deformation increase and have reached a

magnitude of 10

-7

(x 10

-3

m/load cycle). I.e. at the final load

cycles, the specimen´s permanent deformation increased by

only 10 mm at each new cycle.

34,0 21,0

3 19, 311

d

RM

80,0 2

R

Figure 3. Soil with 40% MSW Fly Ash Resilient Modulus vs. Stresses

(21 days of cure)

Cure time 21 days

Cure time 7 days

Without cure time

Figure 4. Resilient Modulus vs. Stress of Soil with 40% MSW Fly Ash

– Cure Time Variation.

Figure 5. Accumulated Permanent Deformation Variation.