3257

Technical Committee 307 /

Comité technique 307

value of the 7-day mixtures was observed as 38.4 while this

value was 78.9 for 28-day mixtures.

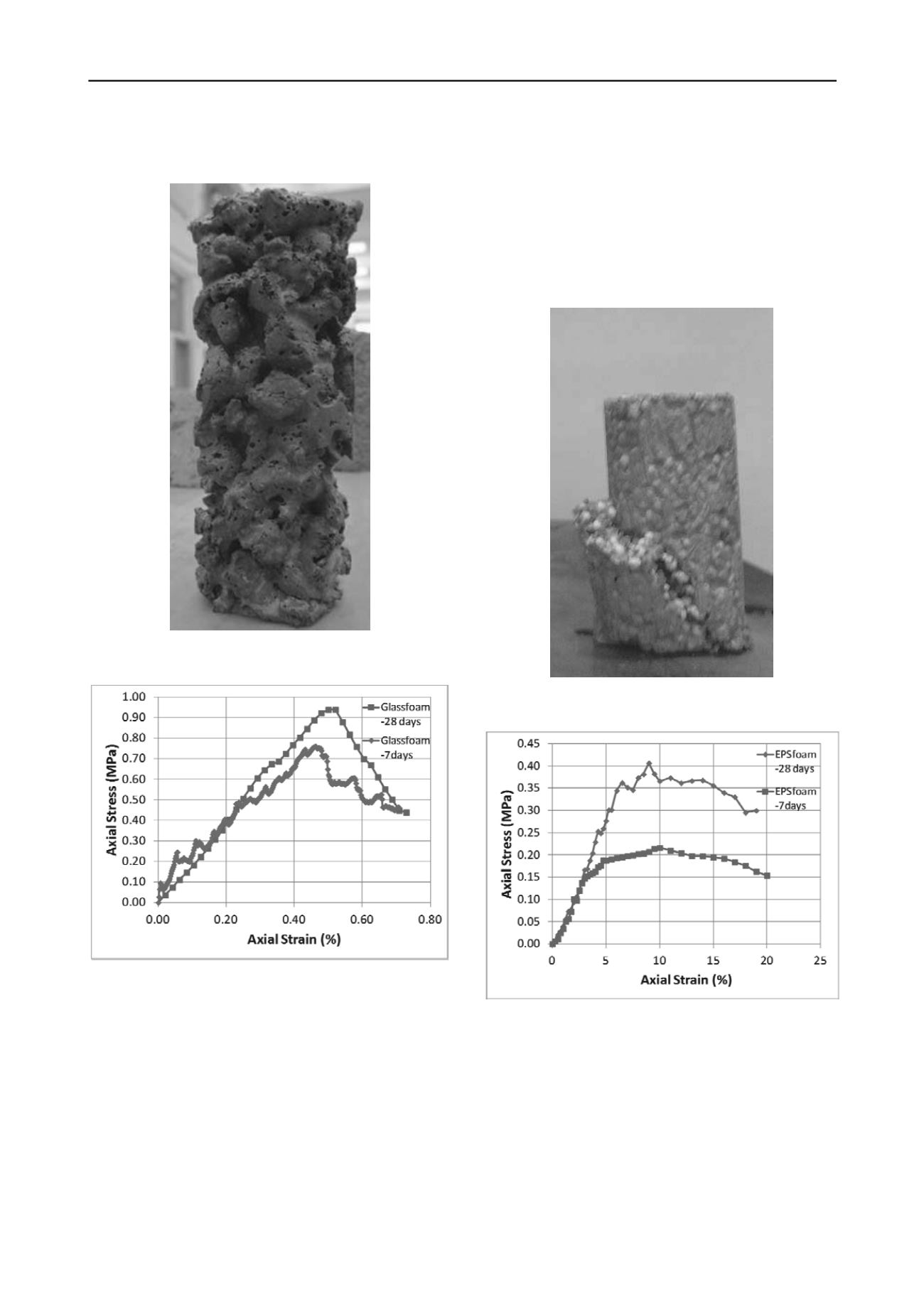

Figure 3. Cement, sand and glass foam mixture sample for the

unconfined compression test (Tuncel, 2012).

Figure 4. 7 and 28 days unconfined compression test results for the

samples with glass foam.

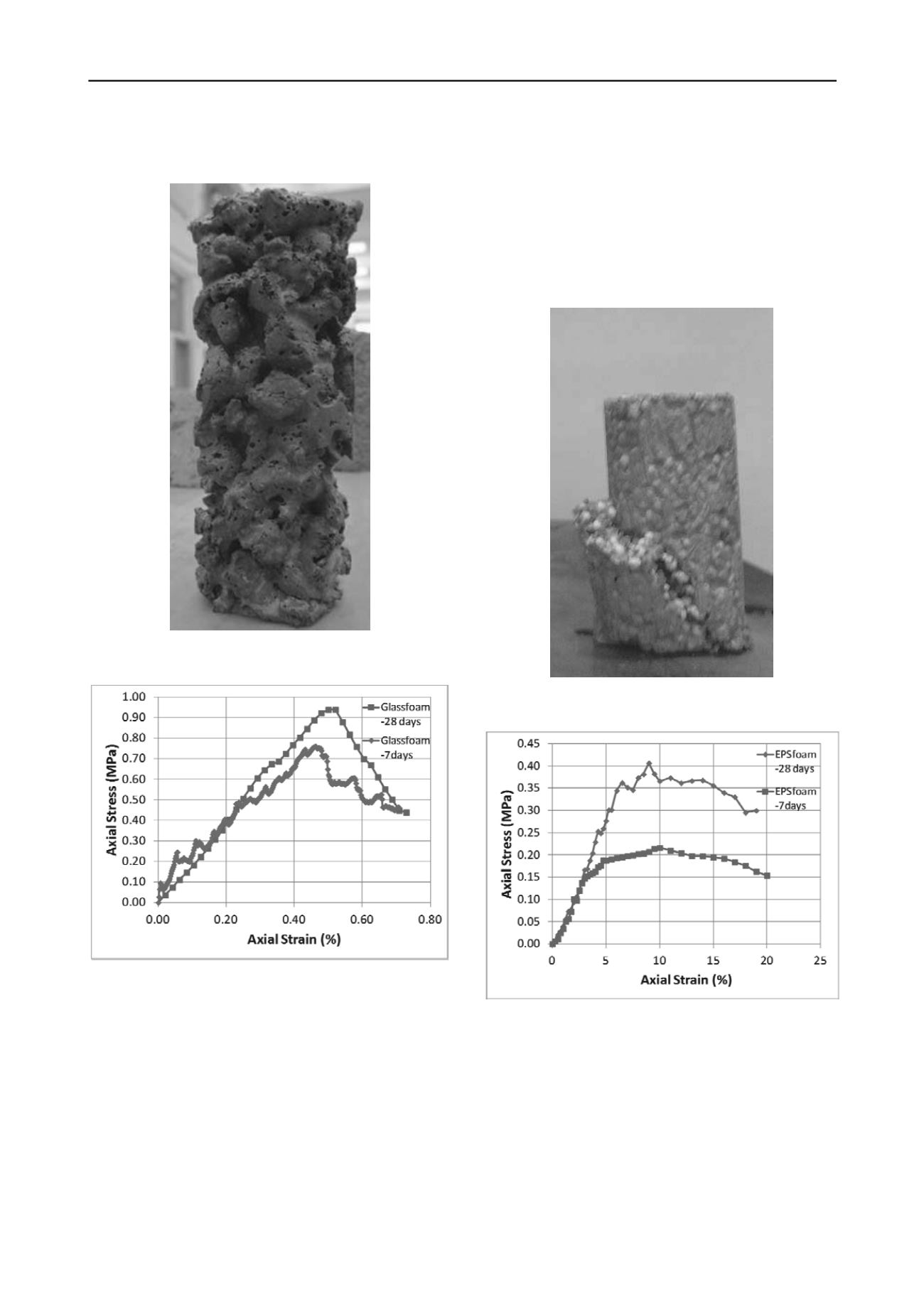

The aim of the laboratory study of lightweight fill that

consist of EPS-cement-sand mixture is investigation for its

usability in geotechnical applications successfully. So for the

solution of weak soils with low durability that have slope

stability problems, it is tried to create more durable and

compressible ligthweight soil than normal soils. The unit weight

of the EPS mixture was 3.80 kN/m

3

. Figure 5 shows the

unconfined compression test sample of EPS, sand and cement

mixture. Weight content of materials in mixture was selected, so

different proportions such as 100%, 75%, 50% and 25% of EPS

content of mixtures were prepared. To determine the ratio of

EPS in the cementious material mixture, where sufficient shear

strength is needed, unconfined compression tests were done.

Prepared mixture samples were tested, then relevant percentage

of expanded polystyrene content of material and

cement/material ratio of mixture was determined. The relevant

content of EPS in material is determined as 50% and ratio in

terms of weight for cement/material of mixture was measured as

12/1. Unconfined compression value of 7 day sample is 0.22

MPa and of 28 day EPS mixed samples is 0.42MPa. According

to the results, the mixture is defined as a low permeable

lightweight fill and it also has CBR value that can be classified

as medium. Figure 6 shows the results of these tests, as can be

seen from the figure with time the strength of the sample

increases.

Figure 5. Unconfined compression test sample of EPS, sand and cement

mixture (Ahmedov, 2012).

Figure 6. 7 and 28 days unconfined compression test results for the

samples with EPS foam.

CBR tests showed that the glass foam-sand-cement mixtures

have enough bearing capacity to be used as a subbase material.

CBR values for 28 days old EPS mixture is 7 making it weak to

be used as a subbase material. As a result, by producing

lightweight fills with CLSM mixture produced using glass

foam-sand-cement can be a solution for consolidation and

bearing capacity problems of very soft soils which continually

consolidate, constitution of geotechnical fills on potentially

sliding slopes and reducing the stress distribution on retaining

structures.