3254

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

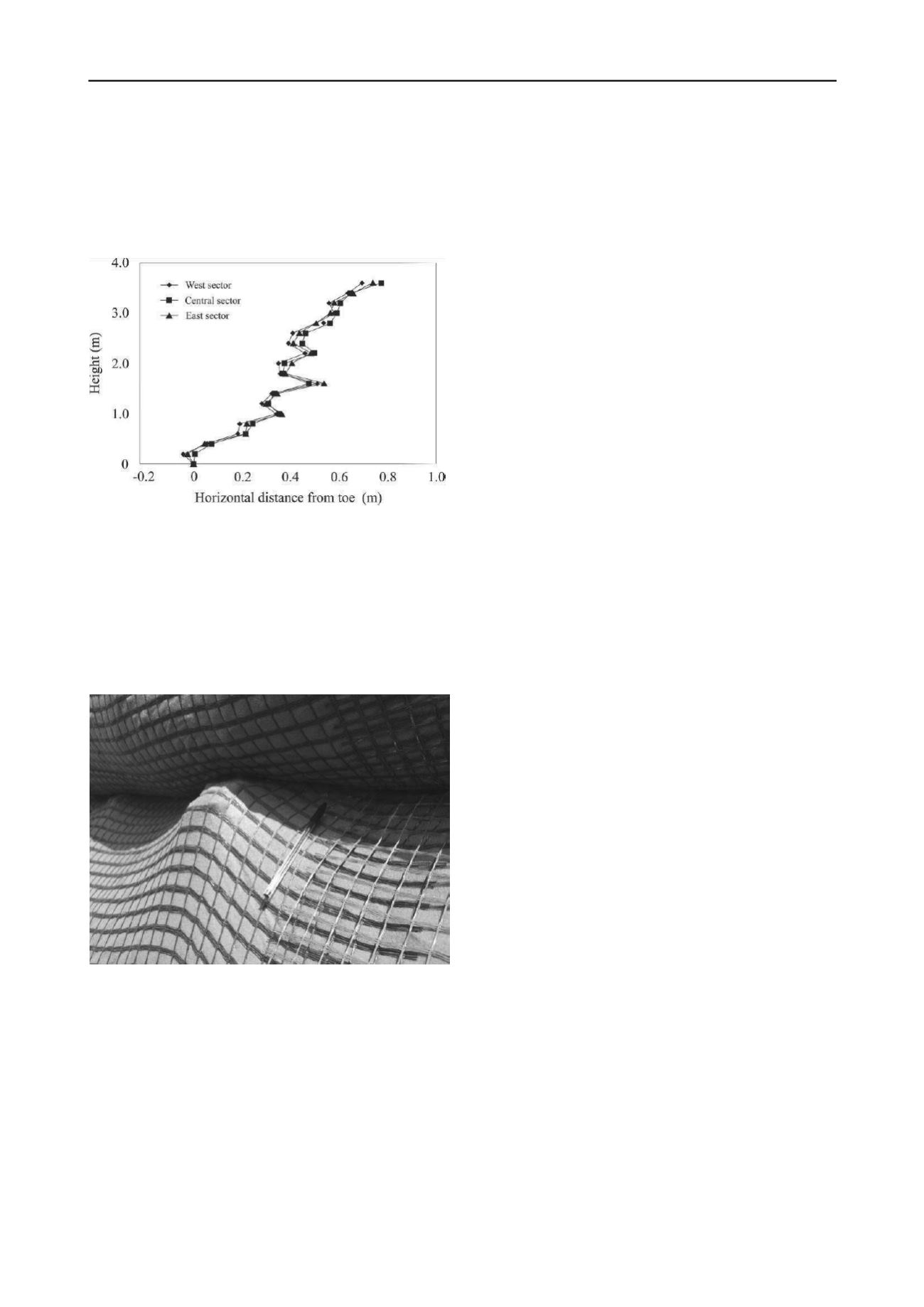

(geogrid) a maximum end of construction face displacement

measured with respect to formwork position of approximately

106 mm. Wall # 2 (geotextile) revealed a maximum end of

construction face displacement - measured with respect to

formwork position - approximately equal to 254 mm. Figure 7

shows wall #1 post-construction face profile.

5 ACKNOWLEDGEMENTS

Funding for the research programme described here was

provided by CNPq, FAP-DF and CAPES. The authors would

like to acknowledge the contribution of the Geotechnical

Research Group at RMCC, FURNAS, EMBRE, REFORSOLO,

ORIGINAL, HUESKER, OBER, LINEA G, TORC, LINEA JR,

ASCOLE, COOPERCOLETA and CAENGE AMBIENTAL.

.

6 REFERENCES

CONAMA – Brazilian Environmental National Council. Resolution nº

307

–

Available

in:

.

Accessed at November 13th, 2006.

Santos, E.C.G., 2007. The Use of Recycled Construction and

Demolition Waste (RCDW) in Reinforced Soil Structures. M.Sc.

thesis, University of Sao Paulo, Sao Carlos, Brazil, 168 pp. (in

Portuguese).

Santos, E.C.G, Palmeira, E.Marques, Bathurst, R. J. 2010 . Construction

of a full-scale wrapped face geogrid reinforced wall using recycled

construction and demolition waste as backfill material. In:

9th

International Conference on Geosynthetics, 2010

, Guarujá-SP

Santos, E.C.G., 2011. Experimental Evaluation of Reinforced Soil

Walls Built with Recycled Construction and Demolition Waste

(RCDW) and Cohesive Soil as Backfill Materials. D.Sc. thesis,

University of Brasília, Brasília, Brazil, 216pp. (in Portuguese).

Figure 7. Post-construction face profile (Santos et al. 2010).

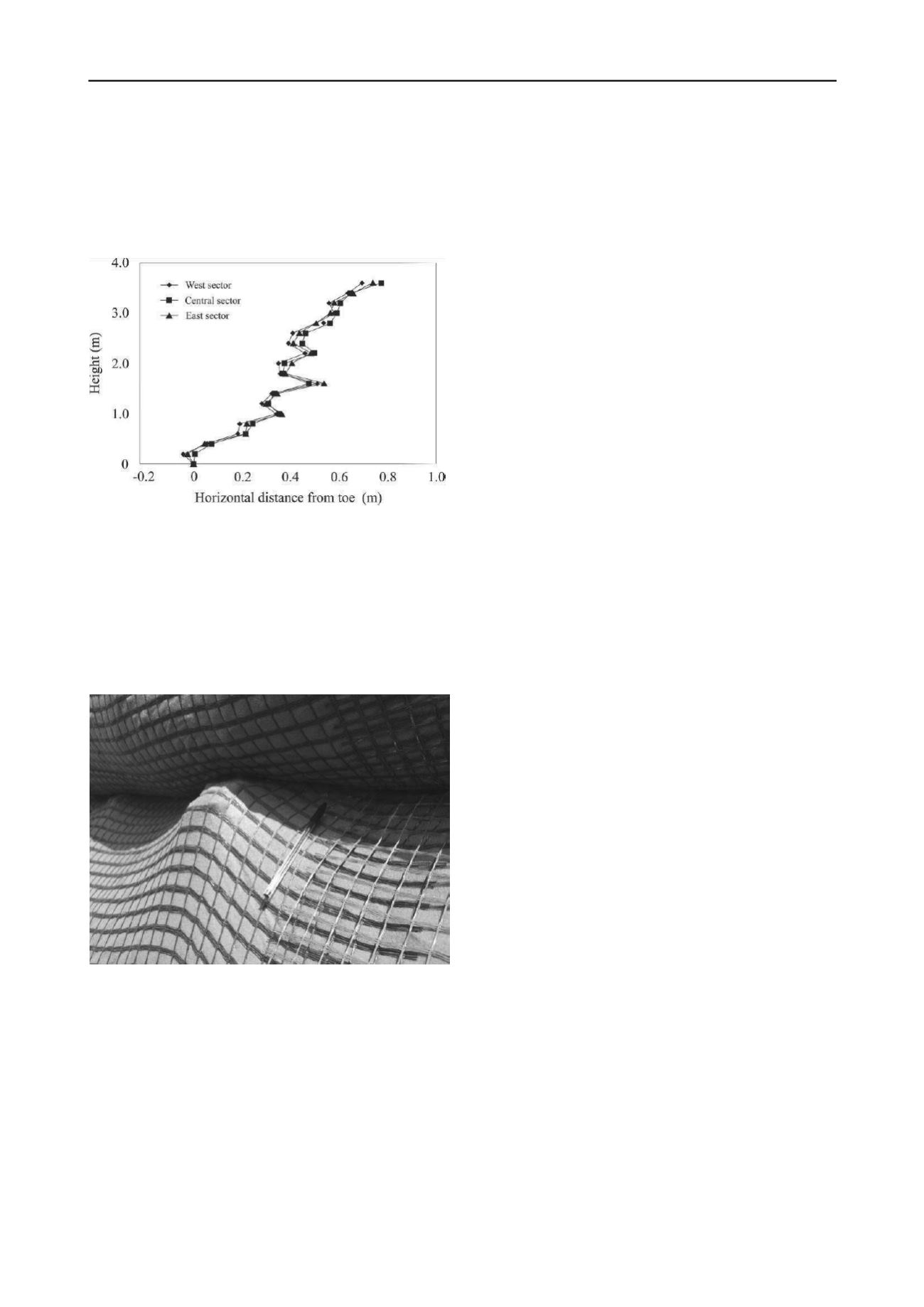

It was noticed for both walls that the presence of coarse

particles near to face was responsible for the uneven surface and

the different magnitude of facing displacements among the

walls sectors at the same layer (Figure 8). Although this fact did

not affect the mechanical performance of the walls, it is strongly

advised to use a selected RCDW near the face in order to

provide a better aesthetic aspect.

Figure 8. Uneven surface recorded at the wall #1 face.

4 CONCLUSIONS

The results obtained in the research programme have shown that

the RCDW used has excellent mechanical properties - with low

variation – which allow its use not just in the suggested

proposal but in other geotechnical works. Additionally, the

adoption of a careful installation process due to the presence of

coarse particles of RCDW seemed to be successful once the

strain gauges presented a high and stable survival level. Based

on lessons learned during the construction process, some

recommendations were presented with aiming at promoting a

better performance of reinforced walls built with this “novel

construction material”.