3244

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

0.0

10.0

20.0

30.0

40.0

50.0

60.0

70.0

80.0

90.0

100.0

0.0

1.0

2.0

3.0

4.0

5.0

6.0

7.0

8.0

9.0

ShearStress (kPa)

HorizontalDisplacment (mm)

10% Cu Slag

50kPa

100kPa

150kPa

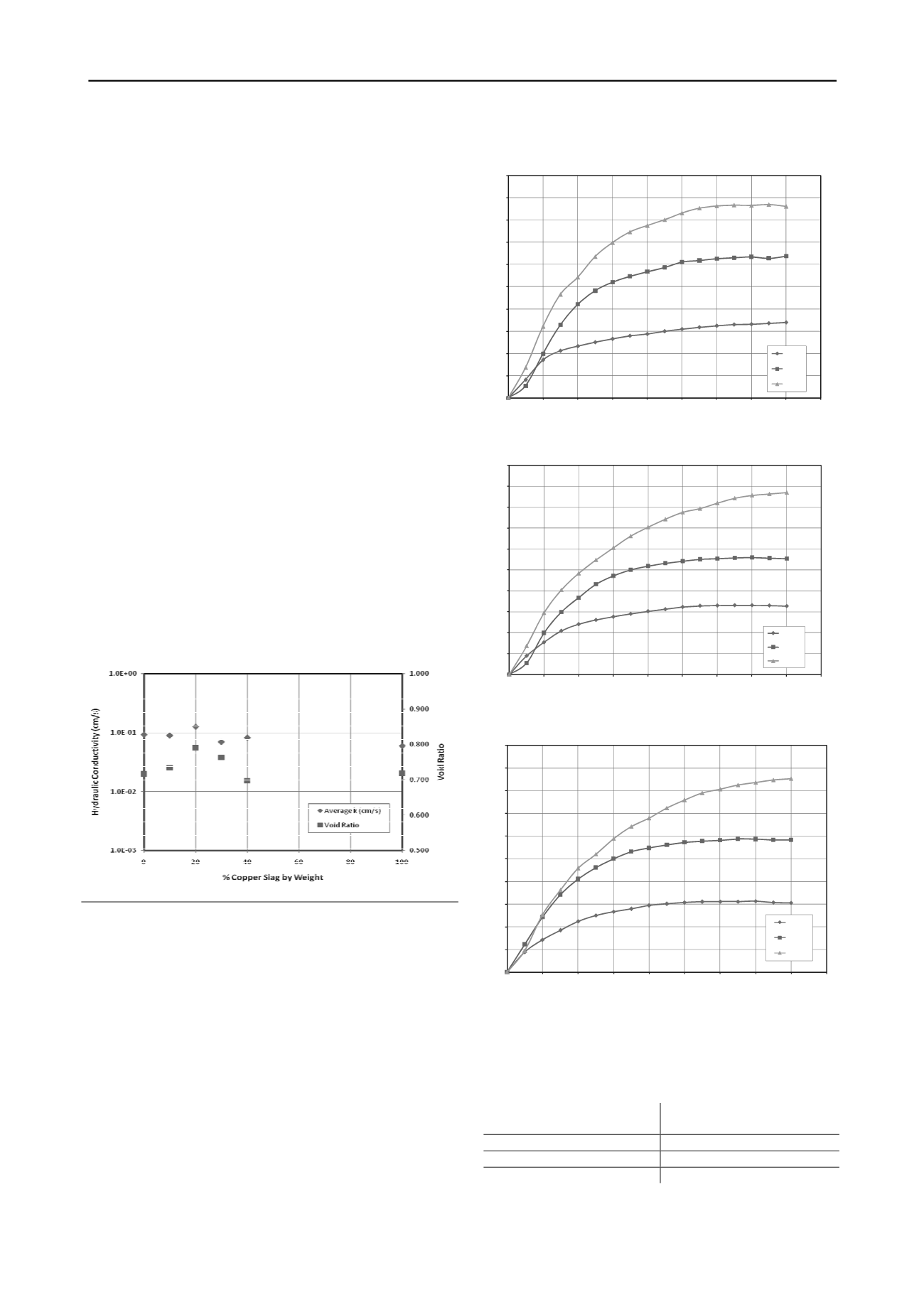

masses by acting as outlets for ground water to flow out. A key

attribute of sand drains is to have very high hydraulic

conductivities so that there is minimal resistance to water

flowing them. High void ratios generally translate into high

hydraulic conductivity thus, a material with high void ratio

would be ideal for used in such drains.

The particle size gradation curves suggest that the hydraulic

conductivity of the mixes should not deviate too much from that

of the original sand. A series of constant head test were carried

out on the each mix in order to check if this was true.

0.0

10.0

20.0

30.0

40.0

50.0

60.0

70.0

80.0

90.0

100.0

0.0

1.0

2.0

3.0

ShearStress (kPa)

Horizont

20% Cu Slag

4.0

5.0

6.0

7.0

8.0

9.0

alDisplacement(mm)

50kPa

100kPa

150kPa

The permeameter was filled with air dried samples of the

copper-sand mix by dropping the material through a funnel

from a fixed height. Special care was taken during the

preparation of the specimens in order to ensure that they were

comparable and consistent among all the different copper-sand

mixes. The funnel used in this case was one from a “Sand

Cone” test used in estimating field compaction values and it was

placed on top of the permeameter. The funnel was first filled to

the brim and the tap was opened to let all the material fall in to

the permeamter in a single step. This method could be estimated

to produce samples slightly denser than those specified in

ASTM D 4254. The unit weight of the specimen was found by

weighing the permeameter and calculating the volumes

occupied by the material.

Specific gravity of the waste copper slag was found to be 3.7

and that of the sand was around 2.65. The specific gravity of the

copper-sand mixes were calculated as a weighted average based

on the proportions of each component. The void ratio of each

mix was then calculated .As expected, the void ratio are tightly

grouped together, ranging between 0.7 – 0.8. There is a trend

showing a peak void ratio at a mix proportion of 20% copper

slag. However, these small differences in void ratios are not

significant enough to affect the hydraulic conductivity of the

materials as can be seen from

Figure 2

.

0.0

10.0

20.0

30.0

40.0

50.0

60.0

70.0

80.0

90.0

100.0

0.0

1.0

2.0

3.0

4.0

5.0

6.0

7.0

8.0

9.0

ShearStress (kPa)

HorizontalDisplacement (mm)

40% Cu Slag

50kPa

100kPa

150kPa

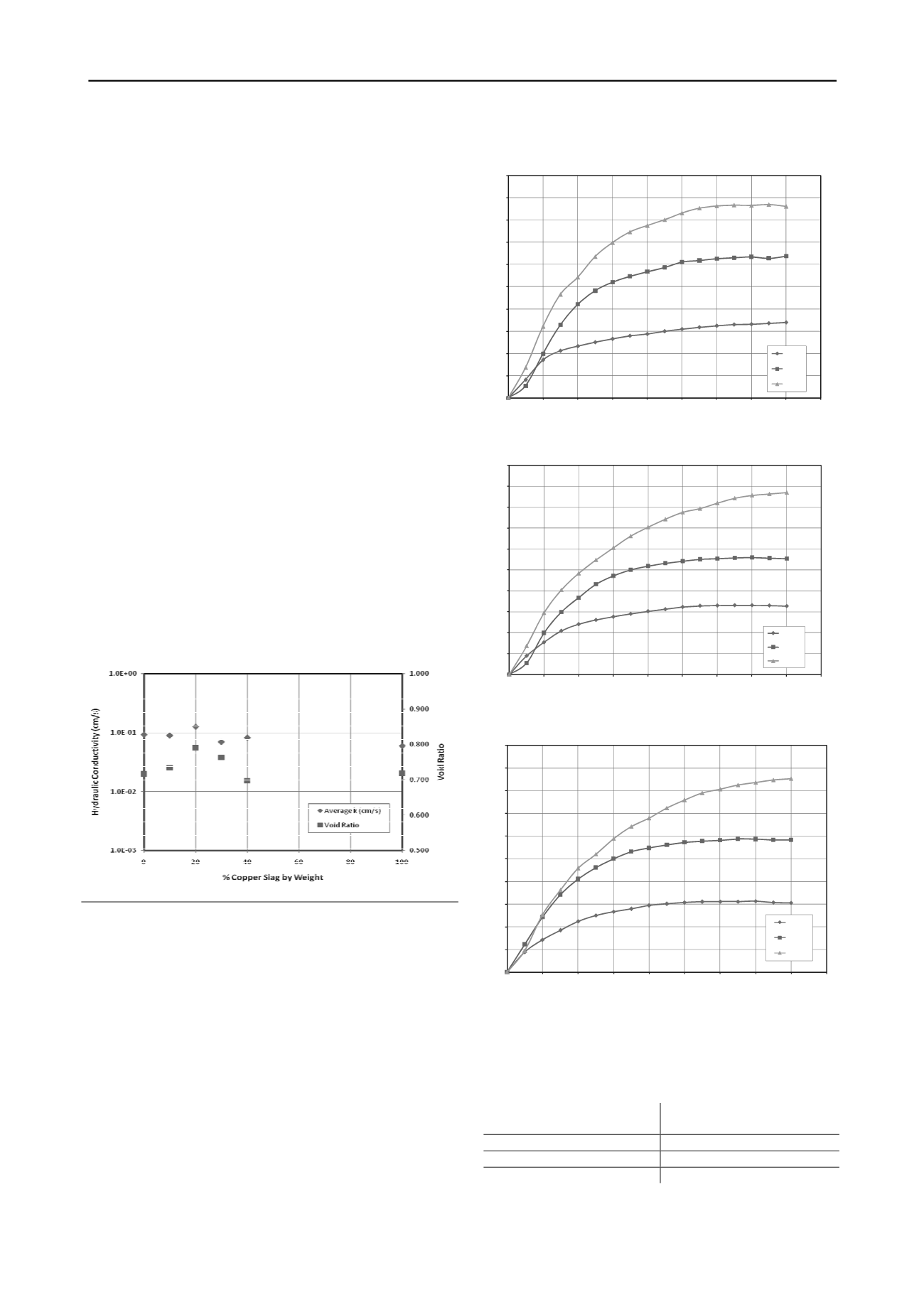

3 SHEAR STRENGTH

The samples which were tested in the direct shear apparatus

were prepared in ‘loose condition’ with no compacting. As

expected, the plots on

Figure 3

are typical of ‘loose’ sand as

they show a gradual gain in shear strength and then flatten out

with no pronounced peak. It can also be seen that the axial

strain required mobilizing maximum shear strength increases

with the increase in the applied normal stress. Figure 6 shows

the summary of Mohr Coulomb failure envelopes for various

copper sand mixes and Table 1 provides friction angles those

mixes.

The direct shear test results show that the addition of waste

copper-slag does not affect the shear strength of the sand. A

friction angle of 30 degrees is typical for a ‘loose’ sand and if

need be, the friction angle can be increased further by

densifying the material.

(a)

(b)

(c)

Table 1: Friction Angles of Copp

Figure 2: Hydraulic Conductivities and Void Ratios for Copper-Sand

Mixes

Figure 3: Direct Shear Test Results on Copper-Sand Mixes

er-Sand Mixes in ‘Loose’ State

es)

% of Copper Slag by

Weight

Friction Angle (degre

10

31.4

20

30.4

40

30.4