3237

Technical Committee 307 /

Comité technique 307

Following backfilling of the craters, earthworks were

undertaken to reshape the surface of the various benches after

which conventional fill placement was carried out to achieve

design levels. In areas, this required the placement of up to 2 m

of compacted fill which was placed under Level 1 geotechnical

control to the requirements of Australian Standard AS3798 –

1996. As a result of the success of the dynamic compaction

phase (which provided a solid base), the undertaking of

additional earthworks was relatively straightforward with a

compaction requirement of 100% of standard maximum dry

density achieved in all fill areas. Fill materials included the use

of coal washery rejects, a mining by-product from the coal

washing process that is obtained at low cost (typical transport

only) but has very good civil engineering properties for use as

general fill and no negative environmental impacts.

5.3

Site Monitoring

Construction works for the ground consolidation contract were

undertaken in accordance with a Construction Environment

Management Plan (CEMP). The key objective of the CEMP

was to develop a monitory programme for regulatory

compliance and early detection of any significant environmental

or community impacts.

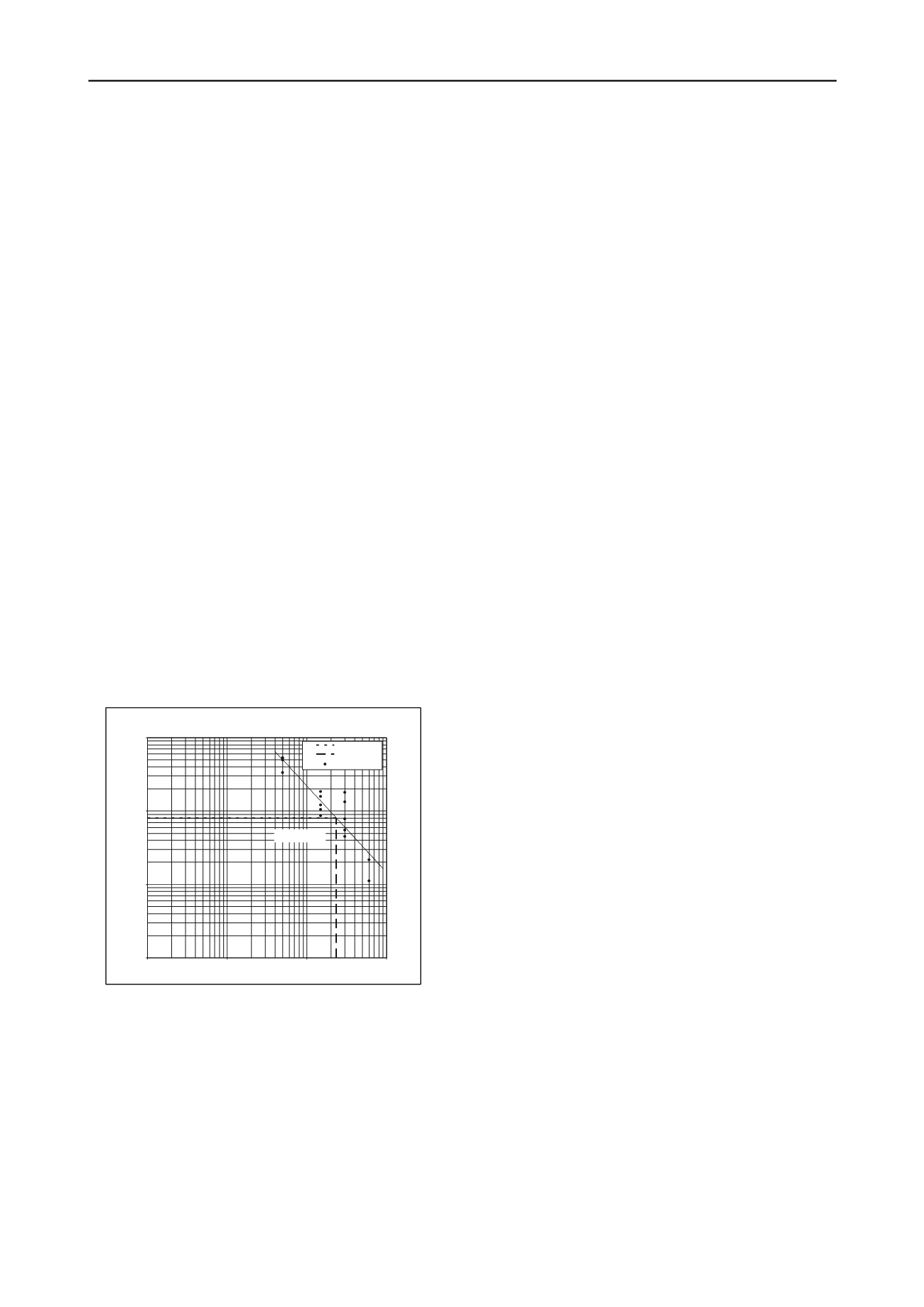

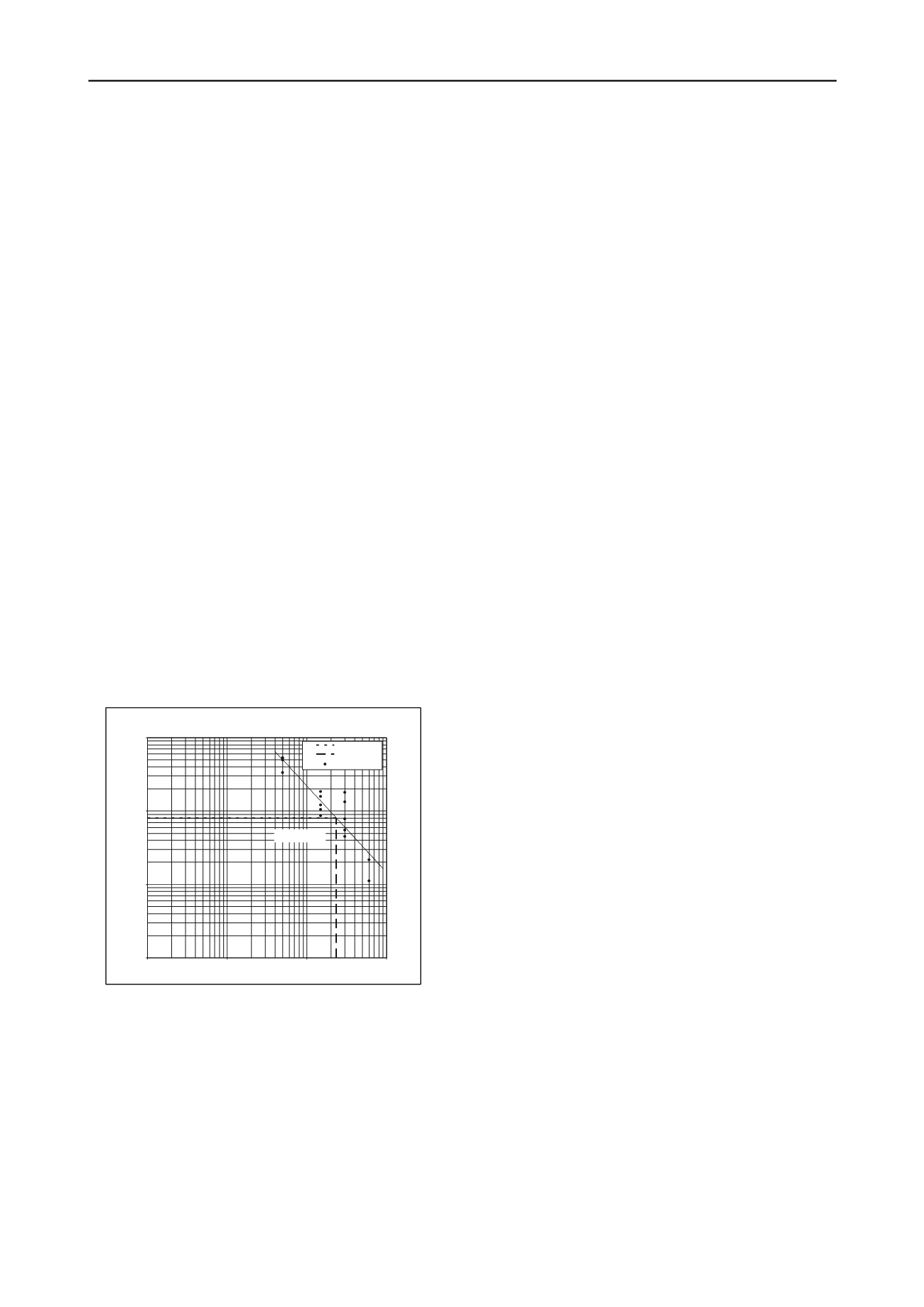

Given the potential impacts due to dynamic compaction

being carried out on the site and the presence of buildings on

neighbouring properties, vibration trials were undertaken prior

to commencement of compaction. An attenuation graph was

prepared as shown in Figure 4 with a boundary buffer distance

of 25 m nominated for a proposed vibration limit of 8 mm/sec

(sector sum and component peak particle velocity). Texcel

Vibration Monitors were installed for continuous data recording

(one of which was in a neighbouring building) and adopting the

buffer distances established by the trial, only nine exceedances

were recorded during the 6 month construction period. No

complaints were received from neighbouring properties.

Figure 4: Dynamic Compaction Vibration Attenuation Graph

Whilst noise was considered to be the other major

environmental impact that could cause community concern

during compaction activities, monitoring over the 6 month

period recorded a total of only 32 readings above the

performance criteria of 75 dBA. Odour was primarily of

concern during the initial excavation phase and was managed by

minimising waste exposure time. Similarly, dust was managed

by the implementation of good construction practices on site.

Leachate and groundwater was monitored regularly with all

outflow to the pre-determined requirements. Whilst results

were typical of those expected from a landfill site, manganese

and ammonia were flagged as elements of concern.

The obvious area of concern in all landfill projects is landfill

gas (LFG). Methane, carbon dioxide and oxygen levels were

monitored both inside and outside the landfill boundary as well

as within site buildings. Daily monitory of landfill was

undertaken using a GA2000 Gas Meter. Both surface and well

measurements were taken as well as barometric pressure and

lower explosive limit. Peak methane levels of up to 97% were

recorded in wells in the landfill footprint, with levels generally

in the range of 14 – 50%. Monitoring in wells adjacent to the

landfill boundary was generally below threshold levels or 0%

methane. Surface and enclosed space monitoring showed that

LFG was not considered to be an issue at any time during the

works.]

6 FUTURE WORKS AND BUILDING DESIGN

6.1

Civil works, services and stormwater drainage

All civil and building services (eg sewer, water, stormwater,

electrical, gas) have been designed such that they will not need

to penetrate the capping layer of the landfill. All service

trenches and other works that require excavation (eg

landscaping) will be within ‘clean’ material and limited to

excavation depths of 2m. Earthworks associated with site

reshaping will require construction of retaining walls up to 7m

high. The walls have been designed as reinforced earth

structures able to accommodate ground settlements of 300mm.

6.2

Foundations

The main advantage of dynamically compacting the landfill is

that long term settlement of the landfill (post building

construction) will be significantly reduced, but not eliminated

(Thom 1998). As such, footing design for buildings located

within the landfill footprint will be for driven steel piles

founding in the underlying latite bedrock. Flexible aprons will

be needed between the buildings (which will experience

negligible settlement) and adjoining carparks, walkways and

recreation areas (which will experience ongoing settlement).

Whilst raft slabs may be feasible for some lightweight single

story buildings, preliminary analysis has indicated that a 1 m

thick reinforced earth raft will be needed to provide uniform

bearing and to equalise the longer term settlements so that

differential movements will be within acceptable limits.

Dynamic Compaction Vibration Attenuation Graph: Nan Tien CampusSite

y = 333.39x

-1.1794

0.1

1.0

10.0

100.0

0.1

1.0

10.0

100.0

Source-ReceiverDistance (m)

Peak ParticleVelocity (mm/s)

Allowed Limit

BufferDistance

TrialData: PPVi

6.3

Leachate Control and Gas Drainage

Leachate collection drains will be installed across the site and

directed to the leachate treatment system. The current options

for leachate collection include disposal to sewer, reinjection,

spray or drip irrigation, removal by contractor, ammonia

stripping, constructed wet lands and membrane bio reactor.

The primary elements of the environmental design are

capping profile, methane drainage and leachate control. The

requirement of the site capping is twofold; firstly – physical

separation by covering contaminated materials and secondly –

prevention of infiltration to the substrate, thereby minimising

leachate recharge and mobilisation and upward migration of

methane. Historically landfill capping systems have included a

0.5 m clay cap however this system alone was not considered

intrinsically safe at this site in areas underneath buildings or

pavements where piles will breach the cap and gas can

accumulate in enclosed spaces.

The preliminary design for the capping consists of HDPE,

GCL, geotextile fabric, 300 mm gravel gas drainage layer and a

reinforcing geotextile, underlain by the existing waste, refer to

Figure 5 below. Undercrofts will be constructed where possible

to allow for suspension of services and cross-ventilation. In

areas outside of the buildings an additional 1 m layer of clean

fill material to further protect the cap from stormwater and root

infiltration, drying out, cracking and accidental breaches will be

installed. The preliminary design requires the landfill cap to