3230

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

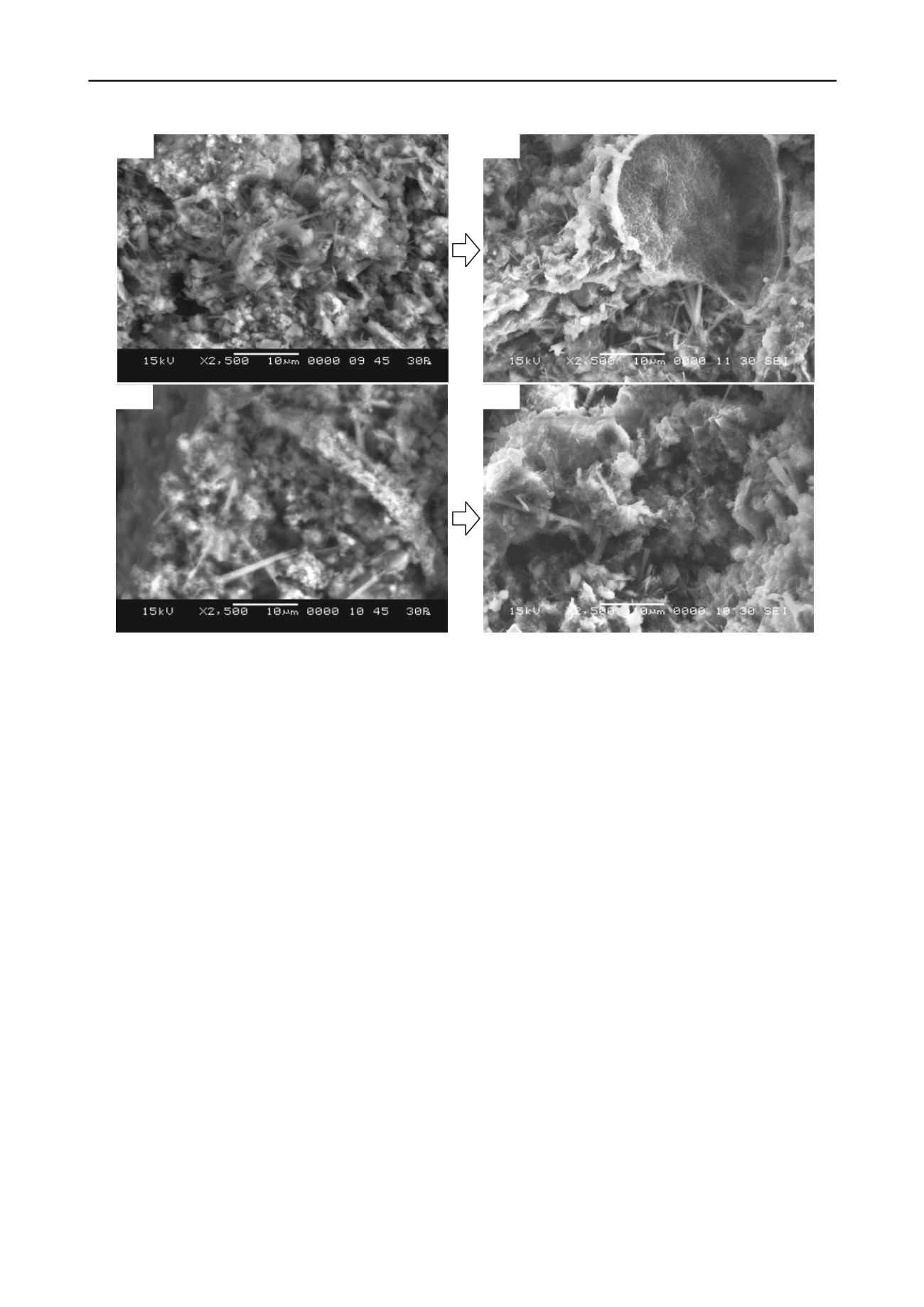

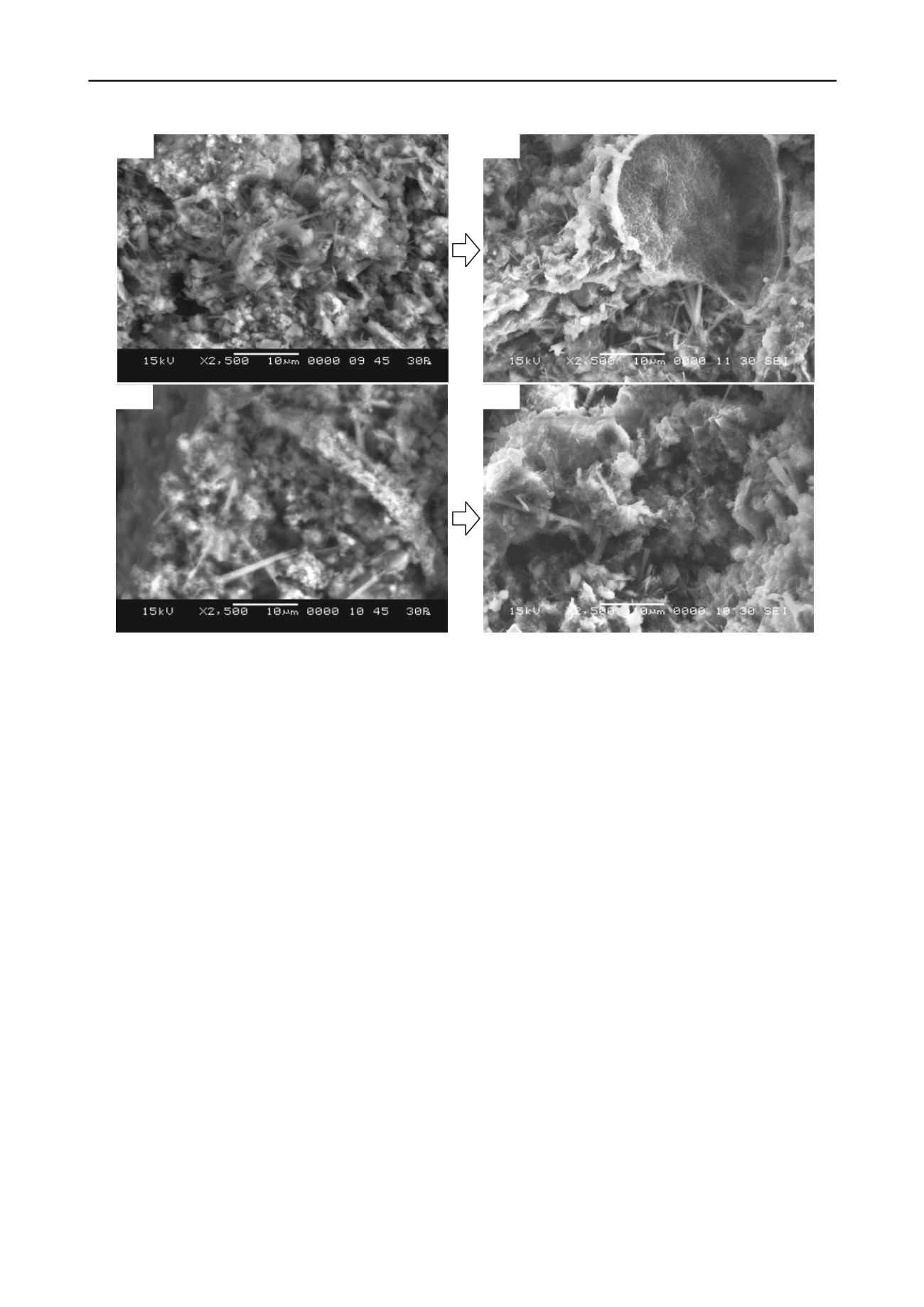

2b

2a

1b

1a

Photo 1. SEM observation of the Tokyo Bay A and B. Curing period of the Tokyo Bay A are 3 (1a) and 182 (1b) days, and curing period of the

Tokyo Bay B are 28 (2a) and 182 (2b) days.

5 ACKNOWLEDGEMENTS

4 CONCLUSIONS

In this study the unconfined compression test, the BE test, and

observations of the internal structure using an SEM were

conducted on SGM specimens prepared with six different types

of source soil to examine how different source soils would

impact the strength development of SGM. The findings are

summarized as follows:

The authors thank Prof. Satoru Shibuya, Kobe University, Japan

and Prof. Satoshi Yamashita, Kitami Institute of Technology,

Japan for help to prepare the soil samples.

6 REFERENCES

It was inferred that while the strength and stiffness of the

SGM specimens increased with the elapse of curing days,

there is a very large variation in their actual levels due to the

mineral components and the constituents of pore water

contained in the source soil used. In addition, it became

clear that the SGM strength cannot be estimated from the

flow values of the specimens.

Kataoka, S., Kawaguchi, T., Horita, T., Tanaka, M., Sakaiya, T. and

Shibuya, S. 2011. Unconfined compression strength and elastic

shear modulus of air-form treated lightweight soil.

Proc. of the 5

th

International Symposium on Deformation Characteristics of

Geomaterials,

2, 682-686.

In SGMs with an approximately equal amount of cement

additive and comparable target wet density, the strength and

stiffness have a linear relationship as is the case in other

cement-treated soil, and their slopes are approximately the

same regardless of the soil type.

Kawaguchi, T., Yamashita, S., Kataoka, S., Shibuya, S. and Kawajiri, S.

2008. Inherent and induced anisotropy of three natural sedimentary

clays reflecting on the elastic shear modulus.

Proc. of the 4

th

International Symposium on Deformation Characteristics of

Geomaterials,

1, 575-579.

The slope obtained from

G

hh

and

G

vh

is characterized by an

approximately 1:1 relationship, showing that the air foam in

the specimens makes SGM a very isotropic material in

terms of stiffness.

Nagatome, T., Mitarai, Y., Yamatoya, R., Kotou, T. and Noguchi, T.

2010. Unprecedented large scale of rapidly construction work of

light weight soil with air form for Haneda D-runway Construction

Project (Part 1: Validation of field mixing condition).

The 45

th

Annual Conference of JGS,

2093-2094. (in Japanese)

Seng, S. and Tanaka, H. 2008. Properties of cement-treated soils during

initial curing stages.

Soils and Foundations,

51 (5), 575-579.

The observations of the internal structure of SGM using the

SEM on the predetermined curing days suggested the

possibility that the increase, growth, and bonding of needle-

like ettringite crystals, formed by the hydration process of

the cement, were a major factor contributing to the

development of the strength and stiffness of the SGM

specimens.

Sibuya, S. Mitachi, T. and Ozawa, H. 2001. Time/stress-history

dependency of deformation-strength characteristics of cement-

mixed sand.

Journal of JSCE,

687 (III-56), 249-257. (in Japanese)

Tuchida, T., Okumura, T., Takeuchi, D. and Kishida, T. 1996.

Development of light-weight fill from dredging.

Proc. of the 2

nd

International Congress on Environmental Geotechnics,

1, 415-420.

Watabe, Y., Itou, Y., Kang, M.S. and Tuchida, T. 2004. One-

dimensional compression of air-form treated lightweight geo-

material in microscopic point of view.

Soils and Foundations,

44

(6), 53-67.