3220

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

centres. Figure 1 shows such a site in central Glasgow, UK

which although measuring just 24 m by 40 m required sixty-two

750 mm diameter bored piles, i.e., approximately one pile every

4 m. The size of the site and the scope of the work meant that

polymer fluids were the only feasible option because they do

not require multiple holding tanks for slurry hydration nor do

they require separation plant to recover the used slurry. Unlike

bentonite slurries, polymer fluids require only a short swelling

and hydration time prior to use and indeed emulsion polymers

develop their properties almost instantaneously after mixing.

Powered polymers, after wetting out, for example, with a

Venturi eductor can be hydrated in an open-top tank gently

agitated with a compressed air lance.

igure 1. The small site in Glasgow where a polymer fluid was used.

nonymous (2001) note that during the construction of the

Cha

nificant environmental benefits

to landfill is banned in many

co

F

A

nnel Tunnel Rail Link (CTRL) East Kent-Ashford to

Cheriton section, polymers were chosen because setting up a

bentonite plant on some of the sites would have been almost

impossible due to space restrictions. The saving of time for site

set-up is an associated advantage. Compact polymer plant can

be moved from site to site relatively quickly whereas mobilising

a bentonite set-up can absorb much valuable programme time.

2.2

Environmental benefits

Polymer fluids can offer sig

when compared to their clay-based counterparts. For example,

although used bentonite may be classified as a non-hazardous

waste, it can be highly polluting if released into the aquatic

environment. For projects near watercourses, polymer fluids are

preferred over bentonite as they need not pose a danger to fish

and in particular they do not build up on fish gills causing them

to suffocate (Schünmann 2004).

As the disposal of liquid waste

untries, the final disposal of used bentonite slurries can be

more costly than the purchase of the original bentonite powder.

Polymers are used at perhaps one-fiftieth to one-twentieth of

bentonite concentrations and the products can be broken down

with readily available oxidising agents such as hypochlorite

(bleach) so that after simple settlement the supernatant water

can be disposed to sewer (with the undertaker’s consent) and the

settled fines added to the excavation spoil – ideally for re-use.

Thasnanipan et al. (2003) report that in Bangkok the primary

reason for switching to polymers was, in most cases, to

minimise the environmental issues associated with bentonite

fluids. Caputo (2009) also expressed concerns regarding the

potential environmental impacts associated with the use of

bentonite for the bored piles for a bridge across the Tagus River

in Portugal.

2.3

Improved foundation performance

As outlined above, operational and environmental benefits are

often cited as the main reasons for using polymers rather than

bentonite. However, over the last two decades many field

studies have been carried out to investigate the effects of

polymer fluids and it is now appreciated that they can bring

significantly improved load performance for piles, etc. The

results of a recent UK case history are summarised below.

To assess the effects of different support fluids and of

varying pile bore open times, Lam et al. (2010a) analysed the

results from a full-scale field trial in East London, where the

ground profile was a layer of made ground underlain by the

Lambeth Group and then Thanet Sand. The trial involved the

load testing of three instrumented piles, two of which were

constructed under a polymer fluid and one under bentonite. The

difference between the two polymer piles was the pile bore open

time; one was concreted within 7.5 h of the completion of

excavation (Pile P1) whilst the other was concreted at 26 h (Pile

P2). The bentonite pile (Pile B1) was concreted at 7.5 h.

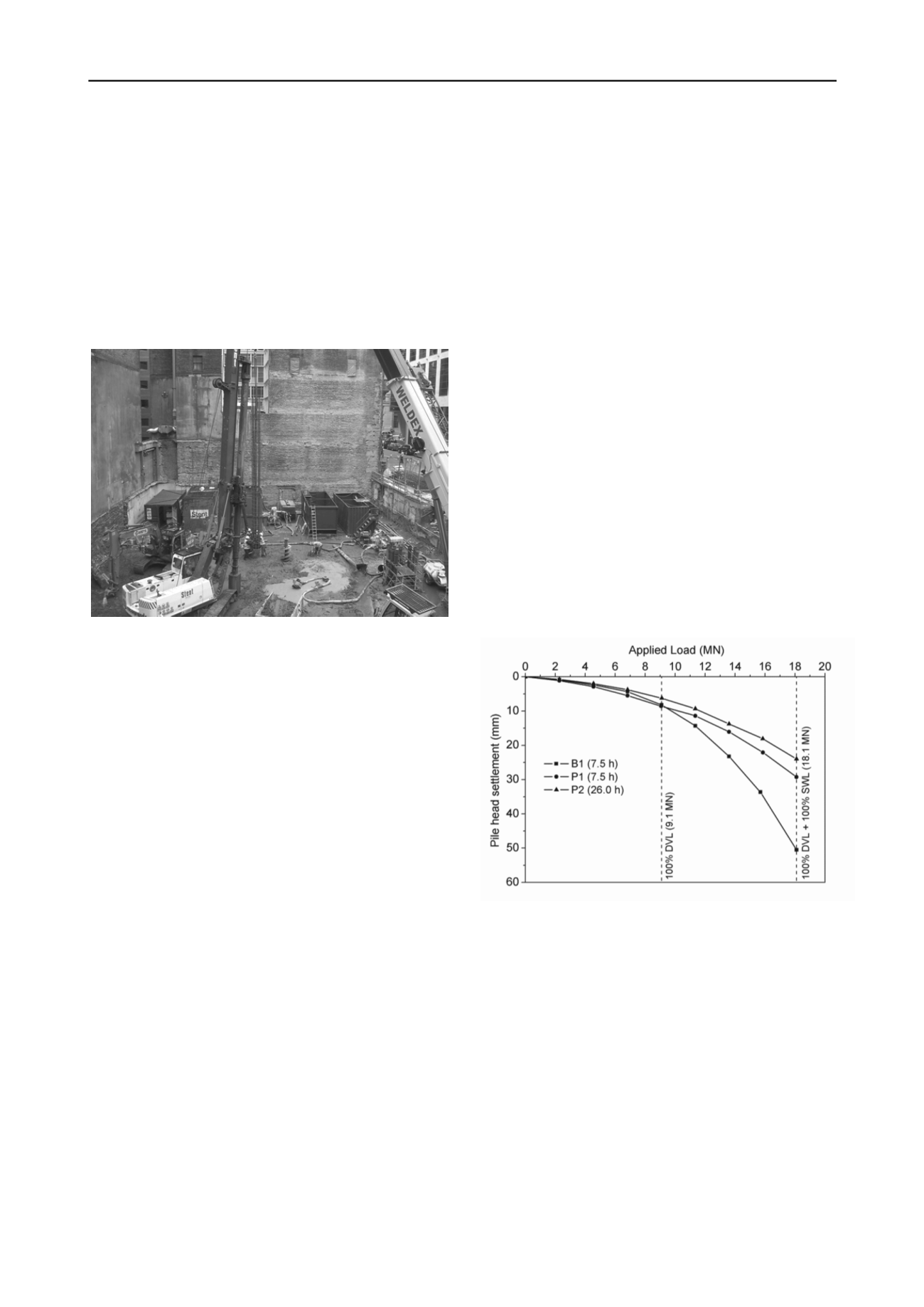

Figure 2 shows the load-settlement curves of the three piles;

both polymer piles behaved similarly and significantly

outperformed their bentonite counterpart at the maximum test

load of 18 MN – and indeed the pile open for 26 h showed

slightly better behaviour than that open to 7.5 h. Analysis of the

data from the instrumentation on the piles and supporting

laboratory tests demonstrated that the improvement in the load-

settlement characteristics of the polymer piles was due to the

higher shaft resistance and also the clean pile bases (Lam 2011).

The effect of the polymer solution on concrete also was

investigated. This showed that the polymer fluid had a similar

effect on the strength and stiffness of hardened concrete as

bentonite slurry – water from the fluids mixing with the surface

concrete being the issue.

Figure 2. Load-settlement curves of bored piles at the East London test

site. DVL: design verification load; SWL: specified working load.

Whilst the above results clearly demonstrate the potential

benefits of polymer fluids, these will be realised only if suitable

excavation tools are used and there is rigorous base cleaning

prior to concreting. Figure 3 shows the auger used for the trial.

This had twin flights which prevent suction developing in the

fluid column as the auger is withdrawn. Spoil loads onto one

flight and the other remains open allowing free fluid flow.

3 FAILURES THROUGH ABUSE OF POLYMERS

The literature reports many case histories of the successful use

of polymer fluids. However, failures can still occur and polymer

fluids can be used less than optimally as a result of lack of

experience and/or understanding of the properties of the chosen

polymer. In the following sections, a few examples of common

polymer misuses are described.