3221

Technical Committee 307 /

Comité technique 307

Figure 3. A twin-flight auger used for the East London trial.

3.1

Failure to use the polymer at the supplier’s recommended

concentration

Suppliers typically recommend that polymer fluids should have

a Marsh funnel viscosity somewhat higher than that for

bentonite slurries. There is therefore a temptation for users to

reduce the polymer concentration and/or for specifiers to require

a lower viscosity. However, the Marsh funnel viscosity of an

excavation fluid is not an indicator of its performance in the

hole rather it is a control parameter to confirm that there is

sufficient active material to develop the required fluid

properties, such as control of fluid loss to the ground,

suspension of cut spoil and inhibition of its dispersion of into

the excavation fluid. Reducing polymer concentration may

compromise fluid performance and should not be attempted.

3.2

Viscosity degradation by fluid recirculation

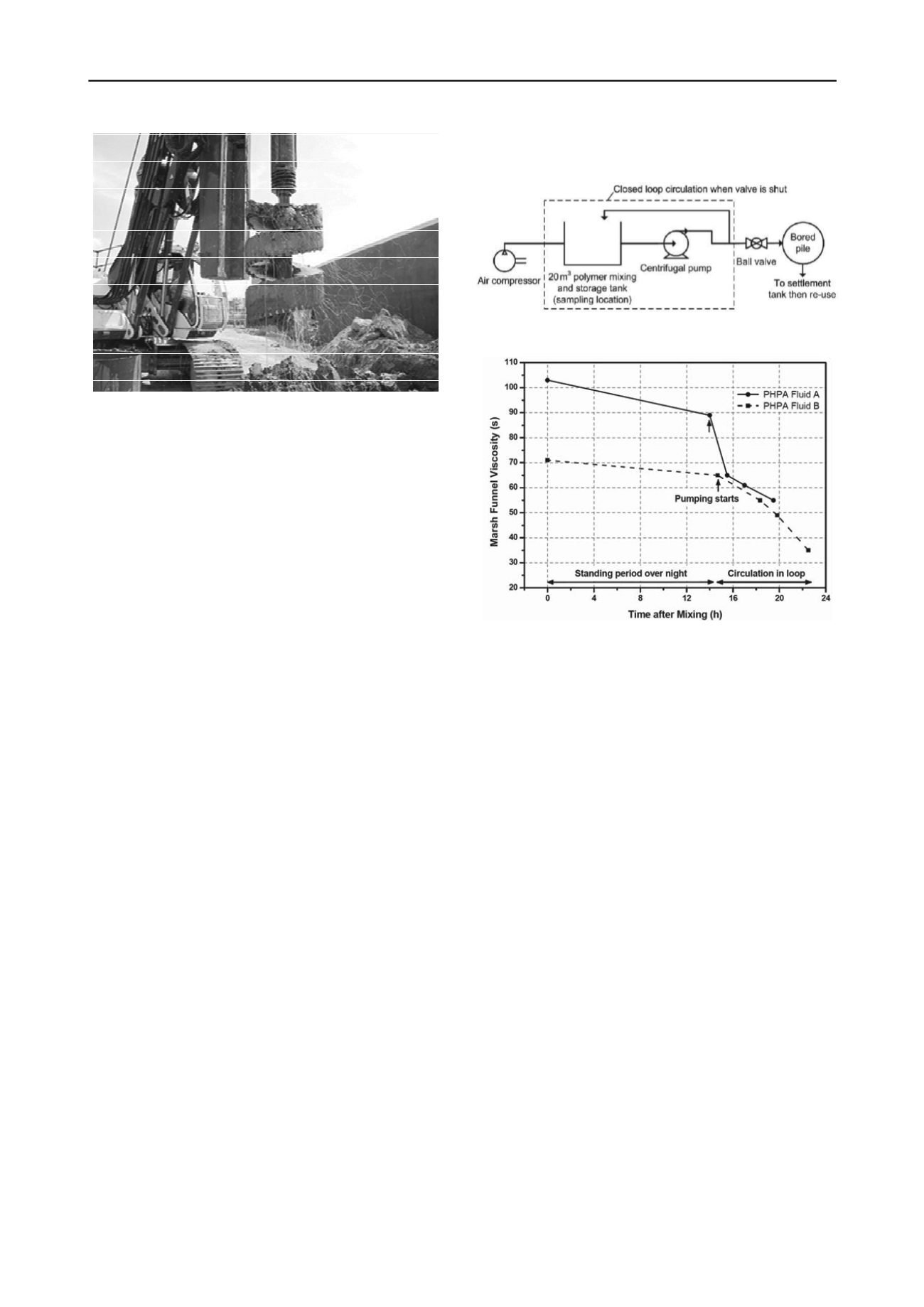

Lam et al. (2010b) report the results of an investigation of the

effects of continued shear on the properties of polymer fluids.

The work was carried out on-site using a typical bentonite slurry

pipework configuration (Figure 4). The centrifugal pump runs

continuously and the fluid is circulated back to the storage tank

when the valve in the feed line to the excavation is closed so

that the pump need not be repeatedly turned on and off during

the excavation. This is an important aspect of plant operation as

the storage tank may be at some distance from the excavation.

Continuous circulation, although wasteful of energy, is

generally regarded as beneficial for bentonite slurries as it

prevents settlement and improves hydration.

Two commercially available polymer products based

partially hydrolysed polyacrylamides (PHPAs) were used for

the study. Each polymer fluid was prepared in accordance with

the supplier’s recommended procedure and allowed to stand

overnight to ensure stable fluid properties. Recirculation

through the pump system was then started with polymer drawn

off for use in pile bores as required. The Marsh funnel viscosity

of the fluid was measured at intervals and the results are shown

in Figure 5. The overnight drop in viscosity was due to the

escape of fine entrained air bubbles which were present in the

fluids after mixing. The effect of air bubbles on fluid viscosity

is not well recognised and initial viscosities can be mistaken for

working viscosities so leading to under-dosage of polymers.

From Figure 5 it can be seen that once pumping started the

viscosity of each of the fluids dropped and continued to do so

up to the end of the test. Both PHPAs were of high-molecular-

weight (i.e. they were long-chain molecules – longer chain

lengths tend to give higher viscosities) and it seems that the

chains were undergoing scission as a result of continuing shear

in the centrifugal pump and pipework so reducing the fluid

viscosity. Indeed the damage was so severe for Fluid B that the

initial 65 s viscosity (after overnight ageing) had reduced to 35 s

at 22.5 h (after approximately 8 h recirculation) and was tending

to that of pure water (28 s).

Figure 4. Schematic diagram of recirculation/delivery system.

Figure 5. Reduction in viscosity of polymer fluids due to recirculation.

As the fluid was being used for pile excavations the viscosity

was boosted by adding polymer directly to the pile bores to

maintain stability and there were no collapses. However, had

the monitoring programme not been in place, the contractor

would not have been alerted to the problem and the pile bores

might have collapsed due to the excessively low viscosity.

To avoid viscosity reduction due to prolonged shear in

centrifugal pumps, it is recommended that diaphragm pumps are

used as they induce less shear and can be designed to stop

automatically (so also saving energy) when the pressure rises as

a result of closure of the delivery valve. If diaphragm pumps are

not available, fluid recirculation should be minimised.

3.3

Fluid-soil/groundwater incompatibility

The viscosity and hence other properties of PHPA fluids can be

damaged by salts present in mix waters and in the ground. To

investigate the effect of salts in mix water, Lam (2011)

measured the viscosity of several commercial polymer products

over a range of sodium chloride concentrations in the mix water

using an Ubbelohde capillary viscometer. Figure 6 shows some

of the test results. It can be seen that above about 100 mg/litre

sodium chloride, the PHPA fluid lost about 60% of its viscosity

in deionised water whereas the blended polymer lost only about

40%. However, for both fluids there was little further effect up

to 1000 mg/litre. The effects of salts in mix water are

recognised by suppliers and are compensated by increasing the

polymer concentration and raising the solution pH with caustic

alkalis – though increase in pH may give limited benefit.

In saline soils there should be regular monitoring of fluid

viscosity to check for viscosity loss; there are case histories of

collapses. For example, on the Vasco da Gama Bridge in

Portugal two of the piles had to be re-drilled following collapses

which were possibly due to fluid contamination (Bustamante et

al. 1998, KB Technologies Ltd. 2000). Schwarz & Lange

(2004) also report a case history of pile bore collapse due to

high concentrations of salts at a site in Benin. Although simple

PHPAs can be adversely affected by salts, engineered polymer