3222

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

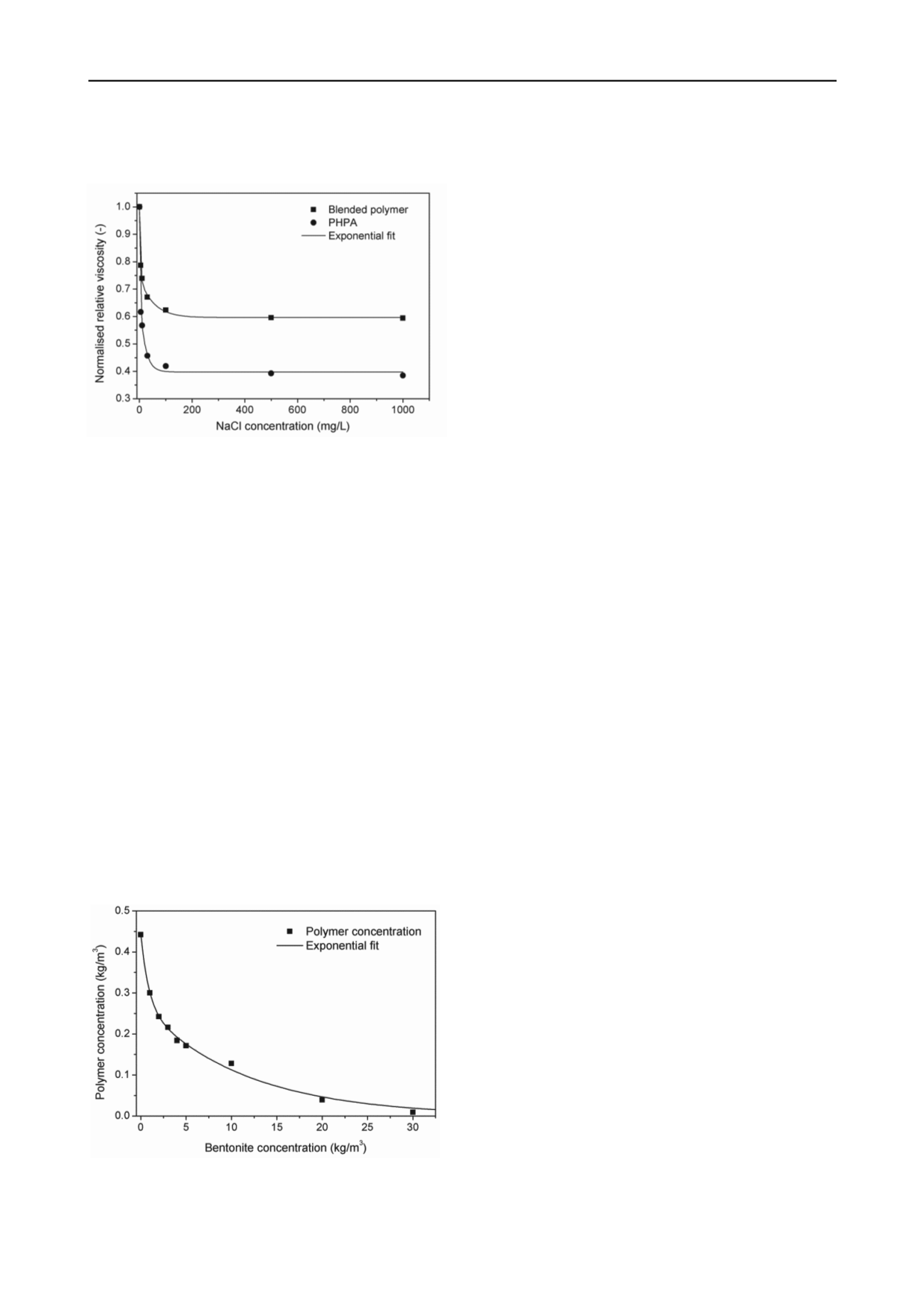

systems are available which are more tolerant of ionic species in

soils and these should be used in saline grounds.

4 CONCLUSIONS

Through the use of case histories and recent research findings,

this paper has outlined some strengths and limitations of

polymer fluids as potential replacements for bentonite slurries

particularly for small or congested sites. Strengths include

improved foundation performance, simpler site operations and

reduced environmental impact. Limitations include reduction of

fluid properties due to continued shear in recirculation systems,

potential for loss of properties in saline soils and importantly

sorption of polymers onto soils – which also can be a benefit as

it reduces dispersion of fines into the fluid. To minimise the loss

of fluid properties, fresh polymer must be regularly added to the

system otherwise a significant degradation in performance of

the fluid and potentially the foundation element will occur.

5 ACKNOWLEDGEMENTS

Figure 6. Effect of added sodium chloride on the viscosity of a

commercial blended polymer product and a pure PHPA both mixed in

deionised water.

3.4

Loss of active polymer concentration due to repeated use

The properties of polymer fluids depend on physical and

chemical interactions between the polymer molecules in

solution. An excavation polymer is thus an active chemical

system. Whilst in use in an excavation, polymers tend to sorb

onto soil surfaces, especially those of clays and this can

beneficially reduce the break-up of lumps of cut soil and the

resulting dispersion of fines into the fluid. However, it does

follow that the concentration of active polymer drops with use

and unless the concentration is regularly re-established the fluid

will become little more than muddy water, a condition which

the authors have dubbed as ‘flipped’. The system has ceased to

be polymer solution with some suspended soil and become a

soil slurry with little polymer remaining in solution.

The work presented in this paper was undertaken as part of a

research project jointly funded by the UK Engineering and

Physical Sciences Research Council (EPSRC), Balfour Beatty

Ground Engineering and KB International LLC. EPSRC grant

reference nos.: EP/C537815/1 (Industrial CASE award) and

EP/H50026X/1 (Knowledge Transfer Secondment). The authors

would like to thank Messrs T. Suckling, V. Troughton,

C. Martin, P. Martin and G. Goodhue for their help and advice

throughout the project.

6 REFERENCES

Anonymous. 2001. Way out of a tight spot.

Ground Engineering

34 (5),

16–17.

Bustamante, M., Gianeselli, L., Boato, R. and Conedera, A. 1998.

Performance of polymer slurries in large diameter bored pile.

Proceedings of the 3rd International Geotechnical Seminar on

Deep Foundations and Auger Piles (BAP III)

, Ghent, Belgium,

A.A. Balkema, 119–127.

Recognition of the effects of sorption is absolutely key to the

management of polymer slurries. With hindsight it is now clear

that a number of past problems with polymers can be traced to a

lack of appreciation of the need to replenish the polymer lost by

sorption and thus a wholly insufficient use of polymer.

Caputo, A. 2009. Instrumented large diameter bored piles.

Proceedings

of the 5th International Symposium on Deep Foundations on Bored

and Auger Piles (BAP V)

, Ghent, Belgium, CRC Press, 213–227.

KB Technologies Ltd. 2000.

A SlurryPro CDP case history: Vasco da

Gama Bridge, Lisbon, Portugal

. Trade literature.

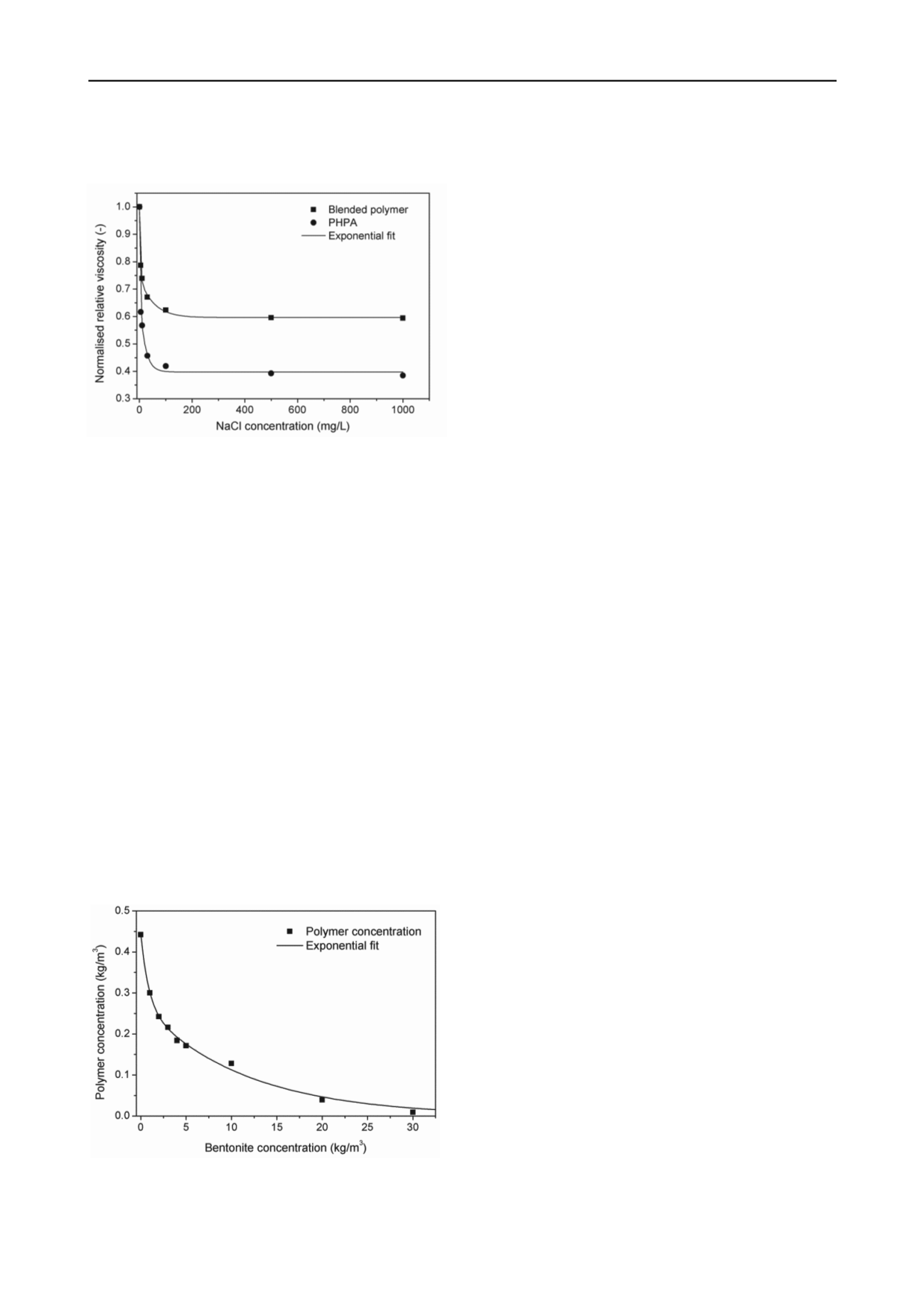

To illustrate the effect of polymer sorption, Figure 7 shows

the results of a series of tests on a PHPA-bentonite mix with

increasing concentration of bentonite; the latter was used as a

soil as it strongly sorbs PHPAs. It can be seen that as the

bentonite concentration in the fluid increases, the polymer

concentration drops and ultimately approaches zero.

Lam, C., Troughton, V., Jefferis, S. and Suckling, T. 2010a. Effect of

support fluids on pile performance – a field trial in east London.

Ground Engineering

43 (10), 28–31.

Lam, C., Jefferis, S.A. and Goodhue, K.G., Jr. 2010b. Observations on

viscosity reduction of PHPA polymer support fluids.

Proceedings

of Sessions of GeoShanghai 2010 International Conference

,

Shanghai, China, Geotechnical Special Publications No. 205,

American Society of Civil Engineers, 184–191.

Lam, C. 2011.

Properties and applications of polymer support fluids in

geotechnical engineering

. DPhil thesis, University of Oxford, UK.

Lennon, D.J., Ritchie, D., Parry, G.O. and Suckling, T.P. 2006. Piling

projects constructed with vinyl polymer support fluid in Glasgow,

Scotland.

Proceedings of the 10th International Conference on

Piling and Deep Foundations

, Amsterdam, the Netherlands, Deep

Foundations Institute, 499–506.

Schünmann, D. 2004. Fisherman’s friend,

Ground Engineering

37 (12),

17.

Schwarz, J. and Lange, U. 2004. Brückengründung mit 70 m tiefen

flüssigkeitsgestützten gebohrten Pfählen in Benin/Afrika.

Proceedings of the 19th Christian Veder Kolloquium,

Graz,

Austria, 73–89 (in German).

Thasnanipan, N., Aye, Z.Z. and Boonyarak, T. 2003. Behaviour of

polymer-based slurry for deep-seated bored piles in multi-layered

soil of Bangkok.

Proceedings of the 4th International Geotechnical

Seminar on Deep Foundations on Bored and Auger Piles (BAP IV)

,

Ghent, Belgium, Millpress, 267–274.

Figure 7. Reduction of polymer concentration by sorption.