3252

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

The RCDW material revealed a low coefficient of variation

with respect to geotechnical properties and low alkalinity

applicable to be used with geogrid products. The mechanical

properties were excellent for the proposed application. The

results of pullout tests with RCDW showed that the recycled

material yielded a better performance when compared with the

standard sand.

Based on the facts listed above and results observed by

Santos (2007) as well as on interesting perspective for the use of

this waste in geotechnical structures, a research programme

aimed at investigating the performance of reinforced soil

structures using RCDW as backfill material started in 2009 at

the University of Brasilia, Brazil.

2 EXPERIMENTAL REINFORCED RCDW WALLS.

2.1

Recylced Construction and Demolition Waste (RCDW)

The recycled construction and demolition waste (RCDW) used

as backfill material consisted of the product of the crushing

process of construction and demolition waste (CDW), which is

composed mainly of mixed materials including soil, bricks, and

small particles of concrete. The RCDW was sampled at the

CDW Re-cycling Plant of Brasília-DF, located at Jockey Club

Landfill (Figure 2). Usually, this material is used by the local

government as cover for unpaved roads.

Figure 1. CDW Recycling Plant of Brasília-DF.

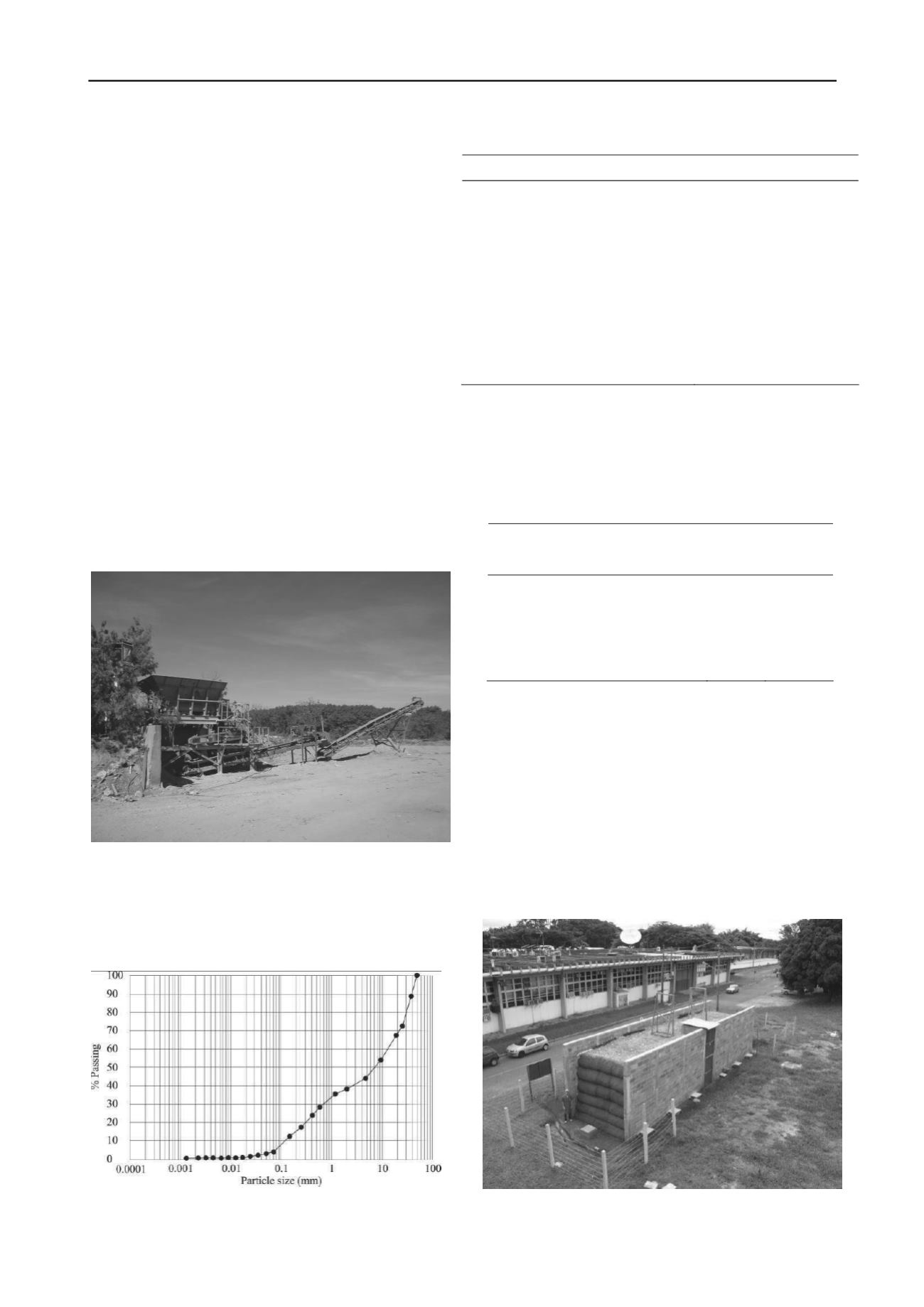

A large-scale equipment was used for the determination of

the RCDW shear strength parameters. Because of the presence

of coarse grained particles (Figure 2), the dimensions of the

shear box used were 800x800x450mm. Table 1 presents the

main geotechnical parameters of the RCDW tested.

Figure 2. RCDW grain size distribution (Santos et al. 2010).

Table 1. Geotechnical properties of RCDW.

Parameter

Value

Specific gravity (g/cm

3

)

2.74

Liquid limit (%)

35

Plastic limit (%)

28

Maximum dry unit weight (kN/m

3

)

16.9

Optimum water content (%)

18

Friction angle (°)

38

Cohesion (kN/m

2

)

14

2.2

Geosynthetics

The geosynthetics used as reinforcement for the walls in this

investigation consisted of a polyester geogrid and a

polypropelene nonwoven geotextile. Table 2 summarizes the

main properties of the reinforcement.

Table 2. Geosynthetics properties.

Data/Value

Parameter

Geogrid Geotextile

Polymer

PET

PP

Longitudinal tensile strength (kN/m)

20

19

Transverse tensile strength (kN/m)

9

21

Maximum tensile strain (%)

12

70

2.3

UnB Retaining Wall Test Facility

Experimental walls were constructed in the UnB Retaining

Walls Test Facility located outdoor at the Foundation, Field

Test and Geosynthetics Experimental Field area. The test

facility was designed to allow two walls to be constructed up to

3.6 m high by 3.7m wide and extending up to 7.2m from the

front edge of the facilityedge. The facility can contain up to 214

m3 of backfill material for the construction of two walls

simultaneously. Figure 3 shows an overview of the test facility.

Figure 3. UnB Retaining Wall Test Facility (Santos et al. 2010).