98

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

Within the range of interest (w/D ~ 0.2 to 0.5), this may be

approximated by a linear ‘plastic’ spring of stiffness

D4~

w

V k

vp

(32)

In addition to the ‘geotechnical resistance’ given by the

above relationships, allowance must be made for buoyancy

effects as the pipeline becomes embedded within the soil

(Merifield et al. 2009). This adds a component of resistance that

effectively increases the shear strength gradient by a factor that

is of the order of 1 + f

'/

, with f ~ 0.15 to 0.25 depending on

the embedment and amount of heave adjacent to the pipeline.

Under dynamic lay conditions, lateral motion of the pipe will

tend to reduce the amount of soil heave adjacent to the pipe.

The linear penetration stiffness allows the complete response

of the pipeline (or SCR) to be determined through the

touchdown zone, using analytical solutions based on a boundary

layer approach (Lenci and Callegari 2005, Palmer 2008, Yuan

et al. 2012). A characteristic length,

, reflecting the length of

the touchdown zone, emerges from the solutions and is given by

0

T

EI

(33)

where EI is the bending rigidity of the pipe and T

0

the

horizontal component of tension in the catenary (Figure 17).

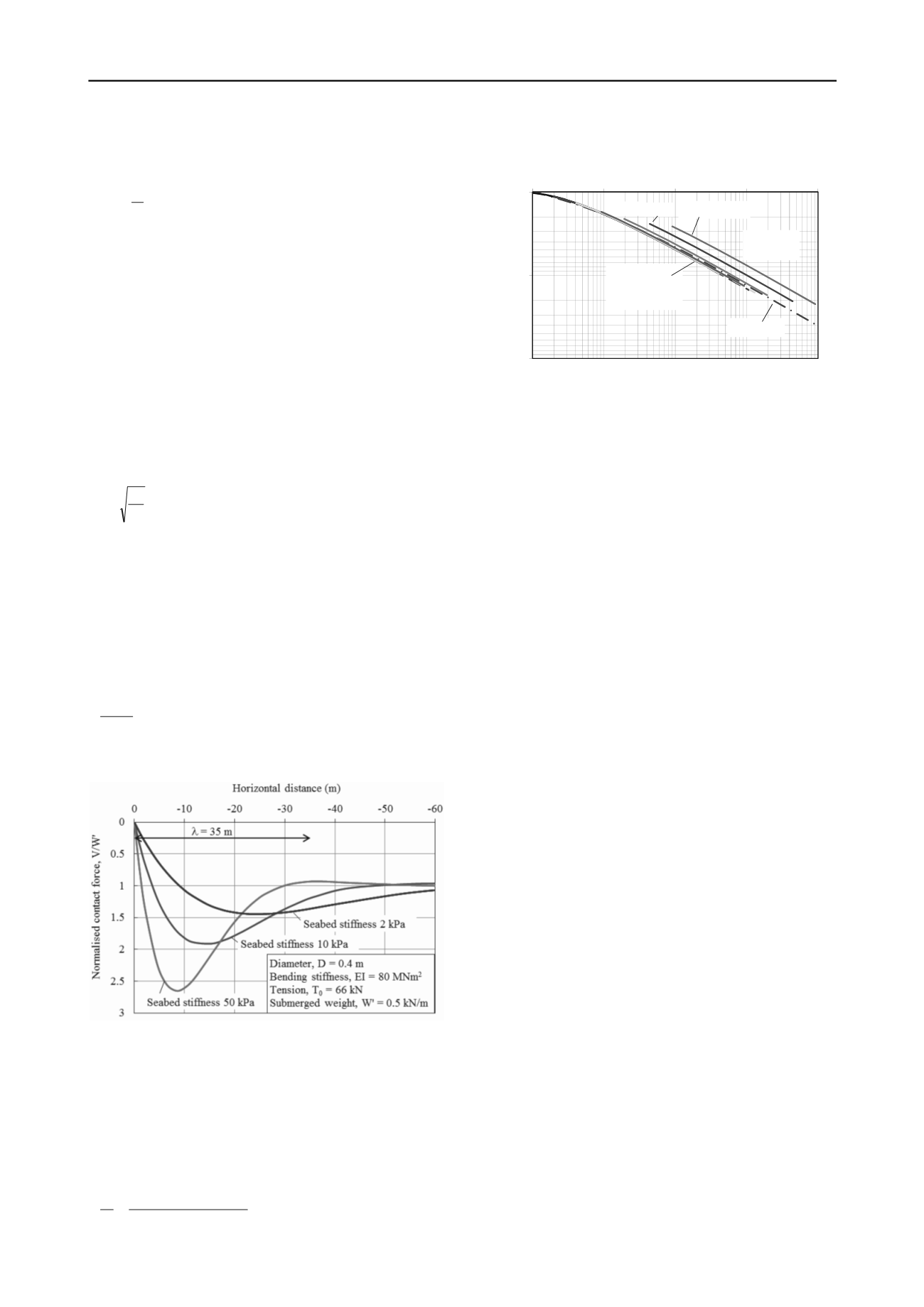

The effect of the seabed stiffness, k

vp

, on the profile of contact

force, V, through the touchdown zone is shown in Figure 18.

The maximum static contact force, V

max

, normalised by the

submerged weight of the pipe, W', is a function of the seabed

stiffness, and also of the characteristic length,

, as shown in

Figure 19. The variation of V

max

may be approximated as

(Randolph and White 2008a)

25.0

0 vp

2

max

T/ k 4.06.0~

'W

V

(34)

A typical range for V

max

/W' for deep water pipelines is 1.5 to 3,

as indicated in Figure 18.

Figure 18 Profiles of normalised contact force for different values of

seabed stiffness.

Westgate et al. (2012) suggested that, as a first

approximation, pipeline embedment under typical lay

conditions may be estimated based on the maximum static

contact force, V

max

, and assuming fully remoulded shear

strength for the soil. Combining Equations (32) and (34), but

with the shear strength gradient,

, replaced by the remoulded

strength gradient,

rem

=

/S

t

, then gives

'W

D 7

T/D

1

~

D

w

2

rem

25.0

0

rem

2

(35)

1

10

100

1

10

100

1000

10000

Maximum contact force, V

max

/W'

Normalised seabed stiffness,

(k

vp

/T

0

)

0.5

Analytical

solutions

(T

0

/

W'

10)

Curve fit

T

0

/

W'

0.1

0.3 1

OrcaFlex

results

Figure 19 Maximum static contact force in touchdown zone (Randolph

and White 2008a).

Effects of buoyancy may be incorporated by adjusting W'

iteratively, or by factoring the remoulded strength gradient by

1 + f

'/

rem

, taking f in the range 0.15 to 0.25.

The simple approach of using the remoulded shear strength

balances two compensating factors. On the one hand

assumption of fully remoulded conditions exaggerates the actual

degree of softening under typical lay conditions. This is

balanced by using the maximum static force, V

max

, to estimate

embedment, rather than the maximum dynamic force, V

dyn

,

which is typically 25 to 50 % greater than V

max

but can be even

larger in more severe sea states (Westgate et al. 2010).

A more refined treatment of pipeline embedment was

described by Westgate et al. (2013), taking account of:

The estimated number of motion cycles experienced by

each section of pipeline as it passes through the touchdown

zone.

Combined horizontal and vertical motions.

Gradual softening of the soil resulting from cumulative

displacement of the pipeline relative to the soil due to the

cyclic motions.

The approach builds on the model for cyclic degradation of the

resistance of full-flow penetrometers during penetration and

extraction cycles (Zhou and Randolph 2009b), but incorporating

a brittle ‘structured’ component of soil strength that is lost

rapidly (Randolph et al. 2007). The effect of horizontal motion

is incorporated by considering theoretical yield envelopes in

V-H space, from which an associated flow rule allows

estimation of the ratio of vertical to horizontal movements

(Cheuk and White 2011).

Although built on reasonable theory, the model incorporates

empirical adjustment factors, which were calibrated through

centrifuge model tests. The model was then applied to three

sites where field data were available from post-installation

surveys, in addition to video footage during the lay process that

allowed estimation of the amplitude of horizontal pipe motions.

The observed pipeline embedment was found to lie within the

range predicted for ‘light’, ‘moderate’ and ‘severe’ sea states

(Figure 20).

Direct application of Equation (35), factoring the remoulded

shear strength gradient, leads to estimated embedment, w/D, in

the range 0.28 to 0.33, which is consistent with the most

frequently observed values. However, it is evident from Figure

20, and other field cases reported by Westgate et al. (2013), that

the pipeline embedment should be considered as a non-

deterministic quantity, varying with lay conditions even if the

seabed properties are relatively uniform along the pipeline

route. This is consistent with modern probabilistic design

approaches for pipelines (White and Cathie 2010). The detailed

treatment for estimating pipeline embedment proposed by

Westgate et al. (2013) allows probabilistic distributions of

pipeline embedment to be derived in a logical manner.