89

Honour Lectures /

Conférences honorifiques

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

2.4

Post-peak strain softening

Axial compression or extension of the pile leads to non-uniform

mobilisation of shaft friction down the length of the pile, with

slip between pile and soil generally being initiated at the

mudline and gradually propagating down the length of the shaft.

Any strain softening in the load transfer response will therefore

allow a form of progressive failure, such that the maximum

shaft resistance will be less than the ideal value for a

hypothetical rigid pile.

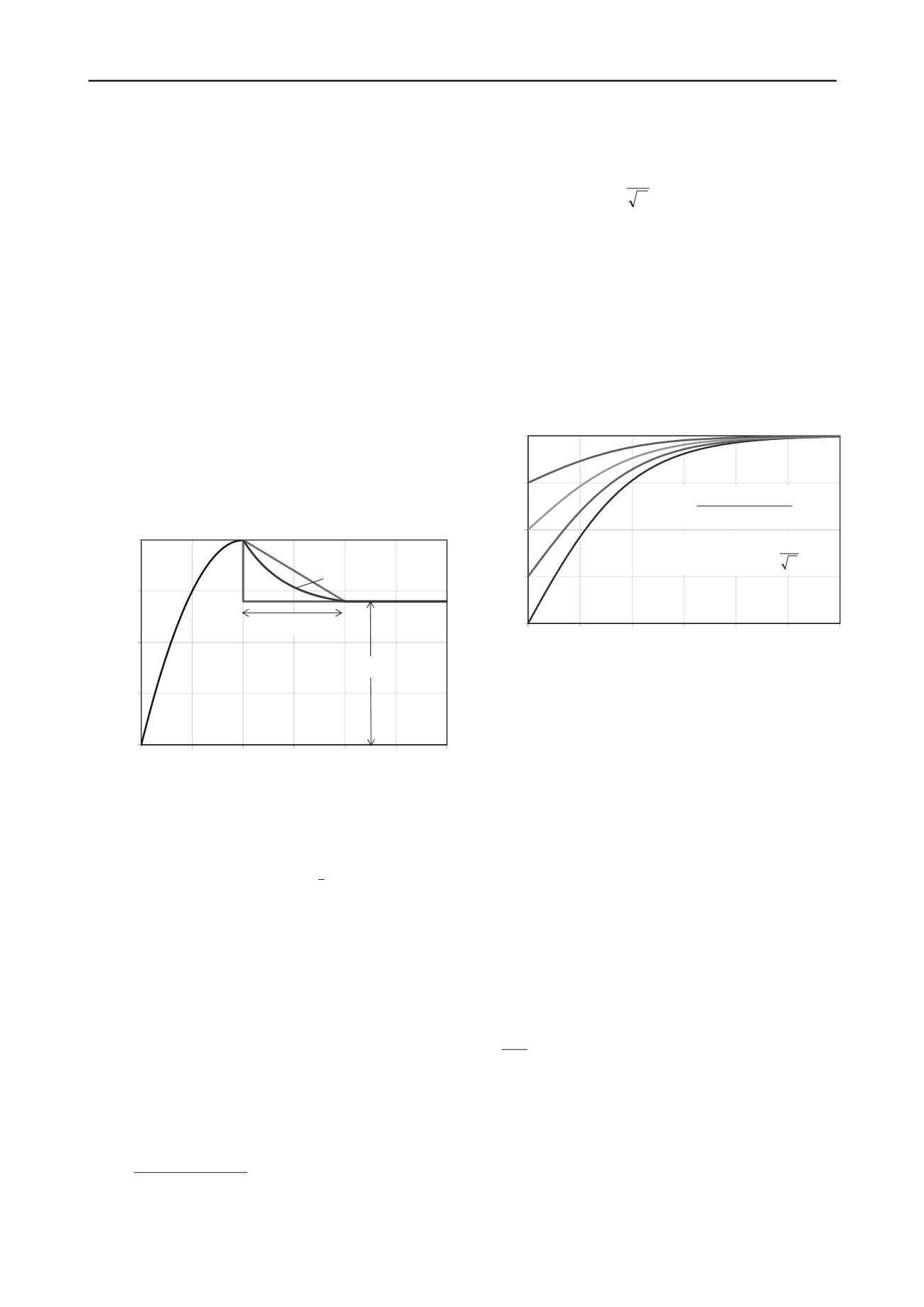

Alternative forms of load transfer curve are shown in

normalised form in Figure 4, with the linear degradation to

70 % of peak shaft friction being consistent with API and ISO

design guidelines for clay. A difficult consideration is how to

scale the degradation response from laboratory to field scale,

and the extent to which a given degree of degradation should be

based on absolute displacement or displacement scaled to pile

diameter. Even though the degradation occurs locally at the

pile-soil interface, the surrounding stress field (and even the

width of the main shearing zone) is affected by the pile size, so

that scaling with pile diameter seems at least partly justified. In

some soil types, much more significant degradation can occur

(Erbrich et al. 2010), possibly occurring over rather greater

displacement than the 1 % of pile diameter suggested in

offshore design guidelines.

0

0.25

0.5

0.75

1

0

0.5

1

1.5

2

2.5

Normalised shear stress,

/

f

Normalised displacement, w/w

f

3

w

res

/w

f

linear

fully

brittle

exponential

Figure 4 Alternative forms of post-peak softening in axial load transfer

curves.

The actual shaft resistance, Q

s

, may be expressed as a

proportion, R

pf

, of the ideal shaft capacity, Q

shaft

:

f

shaft

shaft

pf

s

DL

Q

where

QR Q

(10)

The value of R

pf

will be a function of the degree and brittleness

of strain softening and the compressibility of the pile.

An analytical solution for the extreme case of ‘ìnstant’ strain

softening was given by Murff (1980), who expressed the

reduction factor, R

pf

, as a function of the strain-softening ratio,

=

res

/

f

, and a non-dimensional pile compressibility,

3

. The

latter quantity may be shown to be identical to

L. For strain

softening over a finite distance,

w

res

, Randolph (1983)

proposed an alternative non-dimensional pile compressibility or

compliance, C, substituting the displacement to failure, w

f

, for

the displacement from peak to residual,

w

res

. Numerical

experiments suggest, however, that a more robust measure of

pile compliance, in respect of progressive failure, is the total

displacement to residual, i.e. w

f

+

w

res

, with C defined as:

res

f p

2

f

w w EA

LD

C

(11)

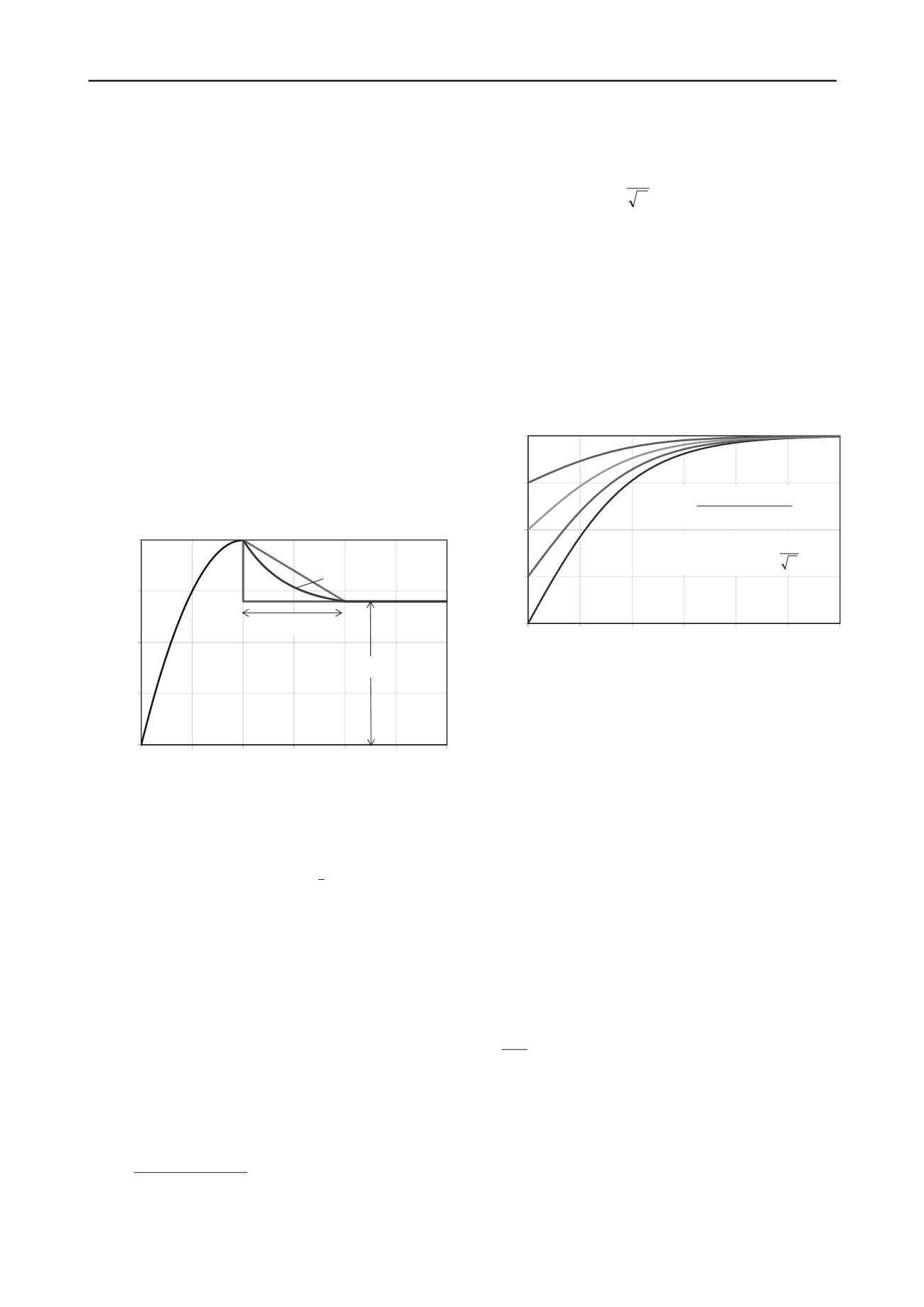

With this definition, the reduction factor can be approximated as

C

1 tanh

1 ~ R

pf

(12)

as illustrated in Figure 5.

This expression provides an initial estimate to assess the

extent to which progressive failure may reduce the net shaft

resistance. The actual reduction factor will depend on the

precise form of the load transfer curve, particularly in respect of

degradation, and should therefore be evaluated through

numerical analysis. A detailed investigation of the performance

of steel jacket structures in Gulf of Mexico hurricanes found

that the one case where axial pile failure occurred could be

explained by progressive failure using the API (2011)

recommended form of load transfer curve with degradation to

70 % of peak friction (Gilbert et al. 2010).

0

0.25

0.5

0.75

1

0

0.5

1

1.5

2

2.5

3

Reduction factor, R

pf

Inverse of square root of pile compliance, C

= 0.75

= 0.5

= 0.25

= 0

res

f p

2

f

w w EA

LD

C

C

1 tanh

1 ~ R

pf

Figure 5 Reduction factor due to progressive failure.

2.5

Lateral pile resistance – clay

Design methodology for the lateral response of piles is almost

universally based on load transfer approaches. These are well-

suited to capture the significantly non-linear soil response,

particularly in the upper few diameters of the pile. However, the

proposed load transfer curves are labyrinthine in formulation

and with no obvious link to any analytical basis. Jeanjean

(2009) has argued for an overhaul of the API guidelines for soft

clay conditions, proposing an alternative formulation based on a

combination of (centrifuge) model test data and finite element

analysis, but with the ultimate lateral resistance at any depth

linked to upper bound solutions (Murff and Hamilton 1993).

The Murff and Hamilton solution addresses soil failure at

shallow depth, based on a three-dimensional conical wedge

mechanism. Below the wedge, the lateral resistance is limited

by plane strain flow around the cylindrical pile (Randolph and

Houlsby 1984, Martin and Randolph 2006). The solutions take

account of the relative roughness between pile and soil, with the

limiting (plane strain) resistance at depth varying with the

friction ratio,

as:

2

p

u

u

34.1 14.4 14.9~N

Ds

P

(13)

From a design perspective, a simple linear fit of N

p

= 9 + 3

is

sufficiently accurate, being generally about 3 % conservative

apart from at the limit of a fully rough pile when it rounds to 12

instead of 11.94.

There is an incompatibility at the transition depth between

the wedge and the plane strain flow, but this does not appear to

have a significant effect on the overall pile resistance, judging

by comparisons with full finite element analyses. The

discontinuity can be removed by allowing a gradual transfer