864

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

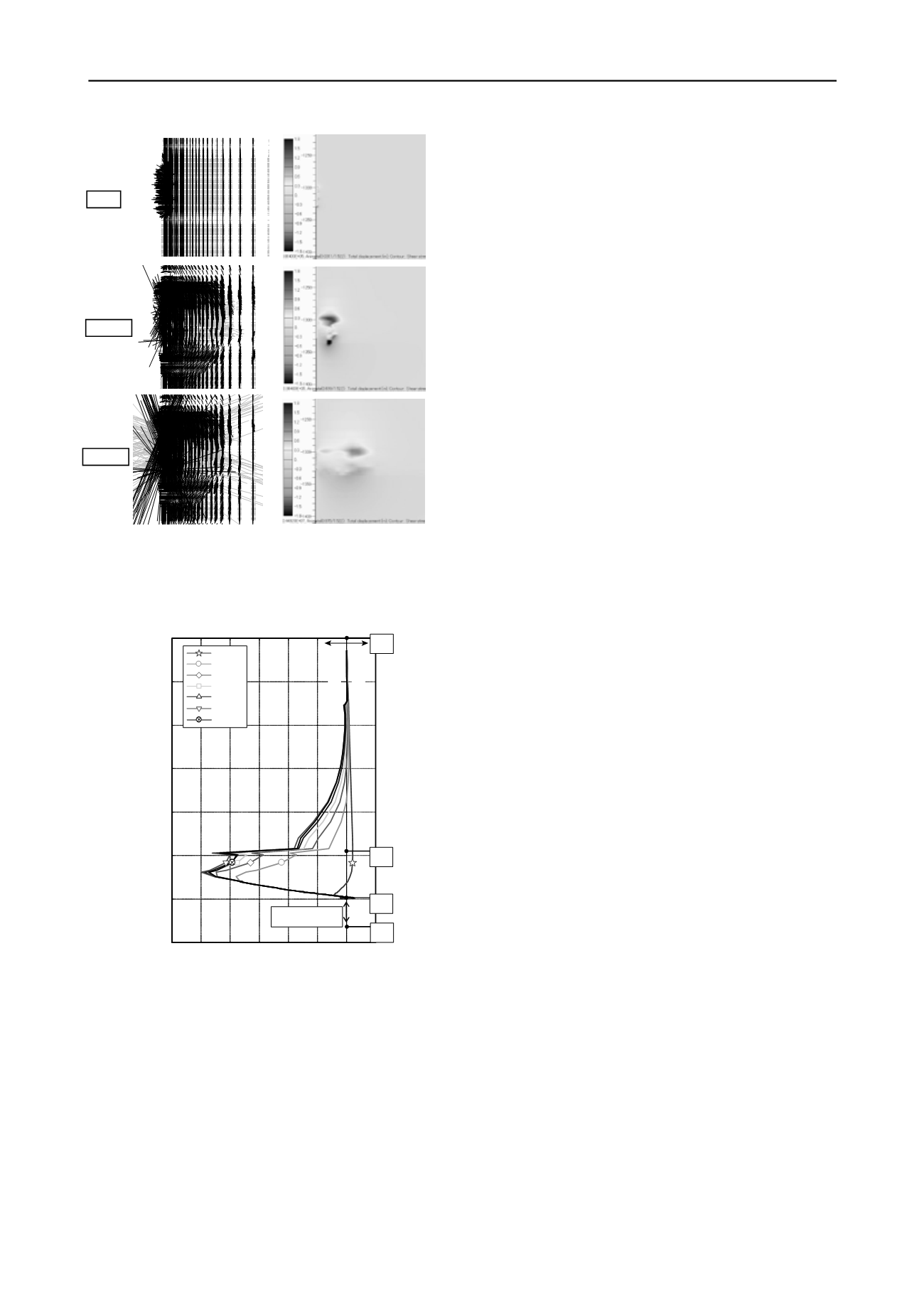

-1.2 -1.0 -0.8 -0.6 -0.4 -0.2 0.0 0.2

-1350

-1300

-1250

-1200

-1150

-1100

-1050

-1000

Normalized vertical stress of cement

1 day

10 days

20 days

30 days

40 days

50 days

60 days

Depth (m)

Tension

Compression

Point D

Point B

Point A

Point C

Depressurization source

Figure 6. Normalized vertical stress

σ

y

of cement

Figure 6 shows the relationship between water depth and

vertical stress of cement during methane hydrate production.

The results were plotted for each different elapsed time, and

compression is positive in the figure. In addition, it was

normalized by maximum stress to make qualitative

understanding easily. Firstly, compressive stress appeared from

seabed to -1280m and tensile stress appeared below on the first

day. The initial stress by self-weight is distributed linearly.

However, tensile stress has occurred because production well

was jerked by the settlement of depressurized area. Ten days

after, tensile stress was applied dramatically on where -1100m

to -1300m. It is considered that the high tensile stress acted on

cement through the interfaces of cement and strata because the

upper layer deform downward by methane hydrate reservoir had

consolidated. The stresses decline 50 days after in this

simulation.

It is confirmed that high tensile stress appear on cement

about 50m range above the depressurization area, and

compression stress appear on open hole which is

depressurization area. Moreover, it became clear that near Point

B where is a junction of a casing and open hole part becomes

neutral point.

6. CONCLUSIONS

A multi phase coupled simulator using finite element method

named "COTHMA" had used for predicting stresses and

deformation of methane hydrate vicinity production well and

the deep seabed ground which simulating NANKAI trough

where is planned as Japan's first offshore production test area.

According to analytical results, depressurization area was

extended rapidly in first 10 days, and the tip of depressurized

area attained 20m from production well. the elements near

production well are compressed by increased effective stress

due to depressurization. Then, a lower part of reservoir heaved

vertically by effect of consolidation centered on

depressurization source with 10 MPa pressure difference. On

the other hand, a upper part of reservoir has deformed

downward into the perpendicular. And there is a neutral section

from depressurization source horizontally which has not

deformed vertically.

The maximum principal stress vectors are distributed like

arch structure over the upper and lower layer. Moreover it have

supported upper layer. Therefore, deformation of seabed ground

near production well is greater than bottom of sea's. However,

high tensile stress appear on cement about 50m range above the

depressurization area, and compression stress appear on open

hole which is depressurization area. It was found that the

settlement of the seabed cause negative friction along

production well.

7. ACKNOWLEDGEMENTS

This research has been conducted under the auspices of the

MH21 Research Consortium on the national methane hydrate

exploitation program planned by ministry of economy, trade

and industry (METI). Thanks are due to our sponsors and

partners.

We appreciate insightful discussions and supports of Dr.

Houlang and Mr. Takiguchi.

8. REFERENCES

Desai, CS, Zaman, MM, Lightner, JG and Siriwardane, HJ. 1984.

Thinn-layer for interfaces and joints,

Int. J. of Numerical &

Analytical Methods in Geomechanics

, 8, 19-43.

Sakamoto, Y, Masayo, K, Kuniyuki, M, Norio, T, Takeshi, K and

Tsutomu, Y. 2009. Numerical Study on Dissociation of Methane

Hydrate and Gas Production Behavior in Laboratory-Scale

Experiments for Depressurization: Part 3-Numerical Study on

Estimation of Permeability in Methane Hydrate Reservoir.

Int J

Offshore and Polar Eng

, 19(2), 124-134.

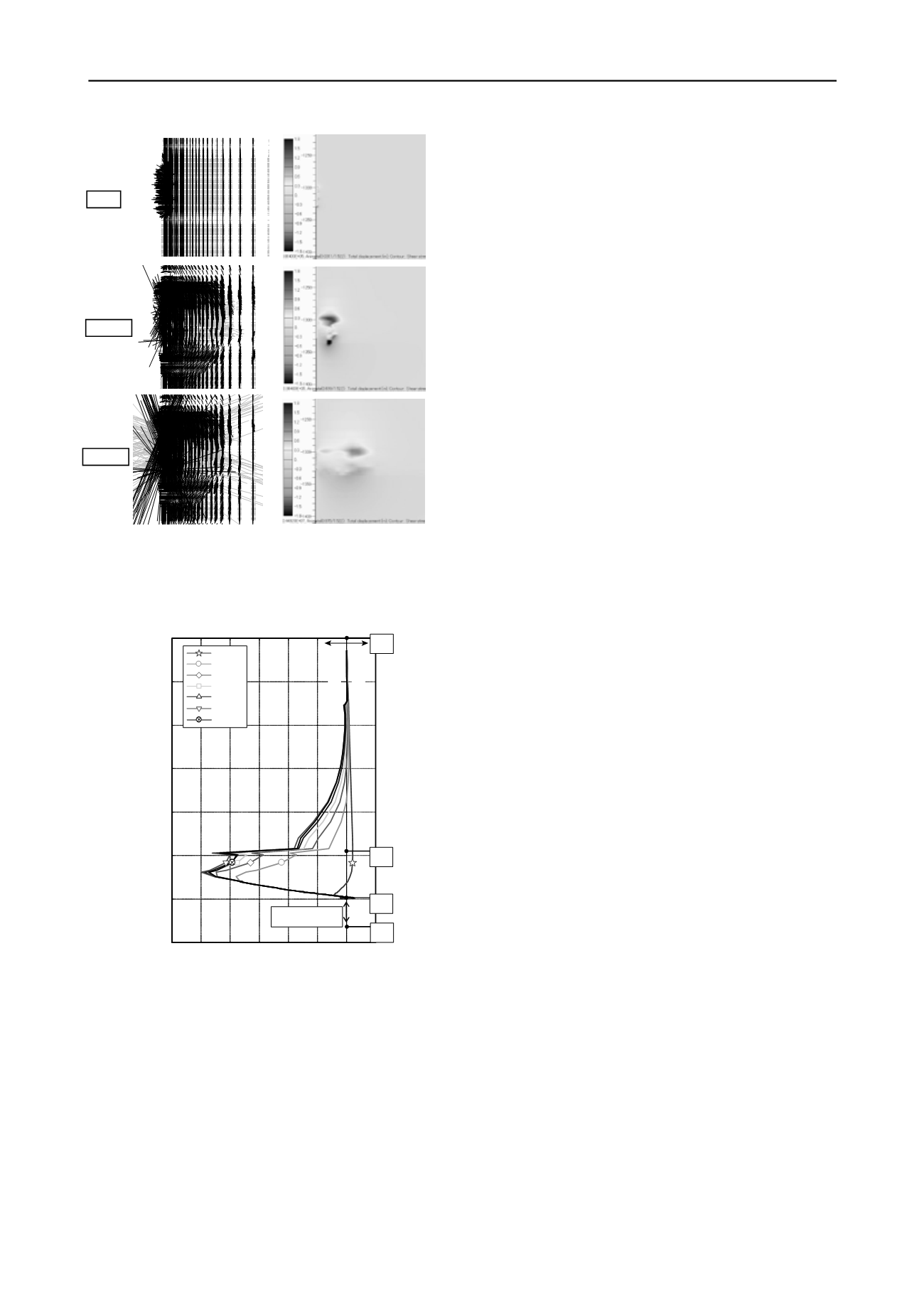

Figure 5. Stress vector and shear strain by depressurization.

(a) Principal stress of each element

near depressurization area

(Maximum stress, Black; Minimum stress, Gray)

(b) Shear stress

1 day

10 days

60 days