94

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

The form of failure envelope adopted by Bransby and

O’Neill (1999) was based on that suggested by Murff (1994):

0 1

s m n

p/1 t

r

q

(24)

where n, m and s represent the mobilisation ratios

(e.g. n = N/N

u

) for normal, moment and sliding modes relative

to the anchor fluke. Ultimate, uniaxial, limits, N

u

, M

u

and S

u

are

typically obtained from a combination of plasticity solutions

and finite element analysis, depending on the anchor fluke

shape (O’Neill et al. 2003, Aubeny and Chi 2010). Similarly,

the various powers may be adjusted to fit different anchor

shapes, with q and t typically in the range 3 to 5, and p, r around

unity (Bransby and O’Neill 1999, Elkhatib 2006, Yang et al.

2010). The values of q, r and t should not be chosen less than p,

in order to guarantee convexity of the failure envelope.

A similar approach was adopted to model the keying of

mandrel-installed plate anchors, such as the suction embedded

plate anchor or SEPLA (Cassidy et al. 2012, Yang et al. 2012).

Combining the chain response with the failure envelope allows

the full kinematic response of the plate anchor to be

investigated. The position of the padeye relative to the plate

centre may then be optimised, minimising loss of embedment

during keying or even such as to cause the anchor to dive. A

careful finite element based parametric study showed that the

original SEPLA design, which incorporated a hinged flap to

help limit loss of embedment during keying, was ill conceived

(Tian et al. 2013). More recent numerical work has considered

sophisticated 3D anchor geometries, investigating how the

presence of the shank affects the failure envelope (Wei et al.

2013).

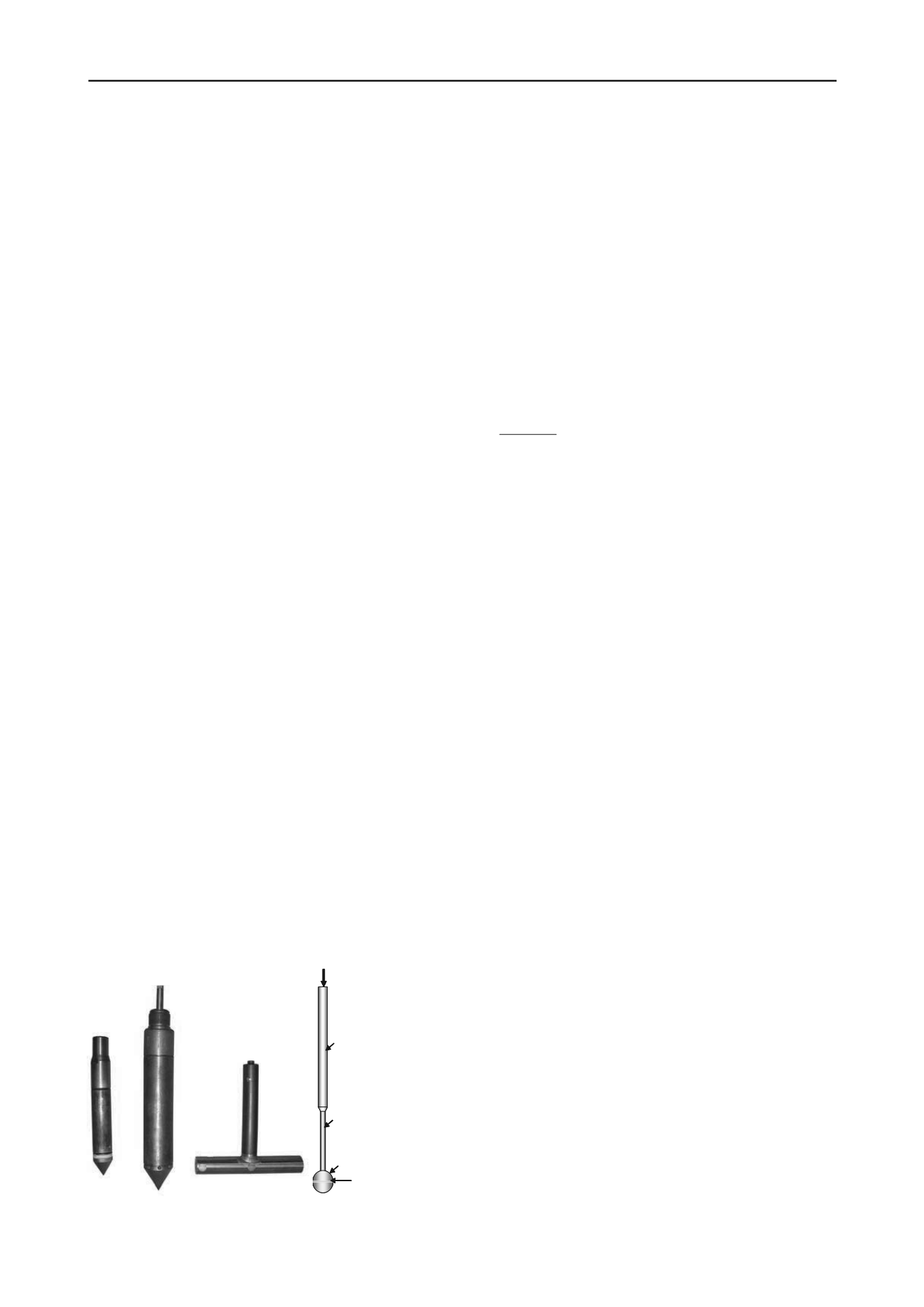

5 FULL-FLOW PENETROMETERS

Full-flow penetrometers, the cylindrical T-bar and spherical ball

(Figure 10), were introduced in the 1990s (Stewart and

Randolph 1994, Randolph et al. 1998). The main motivations

for their introduction included:

Penetrometer shapes that were amenable to plastic limit

analysis, with resistance independent of the pre-yield soil

stiffness.

Sufficient ratio of projected area to shaft area to render

corrections for pore pressure effects and overburden stress

minimal.

Ability to measure remoulded penetration resistance

directly, through cycles of penetration and extraction over a

limited depth range.

Reduced reliance on site-by-site correlations to obtain

resistance factors, and hence shear strength profiles.

The last of these has proved something of a disappointment, not

helped by an embedded culture with respect to interpretation of

cone penetrometer data.

Porewater

pressure filter

Instrumentation,

datastorageand

transmission

assembly

Push rodand

anti-friction

sleeve

Spherical ball

Penetrometer is thrust

intogroundusing

PRODdrill string

(a) Piezocones and T-bar

(b) Ball (Kelleher et al. 2005)

Figure 10 Range of penetrometers for in situ testing.

The relatively large projected areas of 10,000 mm

2

for the

standard T-bar, and generally 3000 to 5000 mm

2

for the ball

penetrometers used offshore, makes them attractive for

characterising soft clay deposits, but still with a capability to

penetrate sand layers with cone resistance of up to 3 or 4 MPa.

In particular, full-flow penetrometers have become the de facto

standard for strength profiling in the upper few metres, with

application to pipeline and riser design. Measurement of

remoulded resistance from cyclic tests, which also help to

constrain the accuracy of the monotonic penetration data, is

essential for pipeline design. While both geometries are used,

with the T-bar having superficial similarity to an element of

pipe, the ball is a kinder geometry and has the advantage of

enabling pore pressure measurement, as discussed later.

Plasticity solutions for the T-bar and ball in ideal (non-

softening, rate independent) soil give resistance factors that may

be approximated by Equation (13) or N

Tbar-ideal

= 9 + 3

, and

2

ideal

ball

u

2

u

06.1 04.5 21.11~

N

sD25.0

P

(25)

for the ball (Randolph et al. 2000, Einav and Randolph 2005). A

close linear fit for the ball is N

ball-ideal

~ 11.3 + 4

. Both sets of

results are for a Tresca soil model, and lead to resistance factors

for the ball that are 22 to 27 % greater than for the T-bar. This

difference reduces using a von Mises strength criterion, for

example down to about 15 % for an interface friction ratio of

0.3. Further reduction occurs for anisotropic shear strengths,

with a difference of 7 % for a ratio of triaxial extension and

compression strengths of 0.5 (Randolph 2000).

Experimental data are mixed in relation to any difference

between T-bar and ball penetration resistance, with some

reported profiles that are indistinguishable (Boylan et al. 2007,

Low et al. 2011), whereas profiles in highly sensitive clays

show differences of up to 16 %. This difference may be

attributed partly to greater reduction in the T-bar resistance due

to strain softening, compared with the ball (Einav and Randolph

2005). For soils of moderate sensitivity, the penetration

resistances for T-bar and ball are mostly within 5 to 10 %,

which is consistent with analytical results that take account of

strength anisotropy.

In natural soils, as opposed to the idealised perfectly plastic,

rate independent material on which plasticity solutions are

based, it is essential to allow for the relatively high strain rates

in the soil around the penetrometer, and also the gradual

softening of the soil as it flows around the cylinder or ball. This

has been looked at using a variety of numerical techniques,

ranging from a combined upper bound and strain path method

(UBSPM; Einav and Randolph 2005), large deformation finite

element analysis (LDFE; Zhou and Randolph 2009a), and a

steady state finite difference approach (SSFD; Klar and Pinkert

2010). All three approaches adopted a similar logarithmic law

of rate dependence, with a relative strength gain of

per tenfold

increase in strain rate, and an exponential softening law with

95 % reduction to the fully remoulded shear strength for a

cumulative plastic strain of

95

. Of the three approaches, the

LDFE analysis tends to give the lowest (average) resistance,

since it is able to capture the periodic generation and softening

of distinct shear bands, accompanied by a corresponding cyclic

variation in the penetration resistance.

Resistance factors evaluated using LDFE analysis (see

Figure 11) may be expressed as (Zhou and Randolph 2009a)

ideal

ball

/

5.1

rem

rem

ball

ideal

Tbar

/

5.1

rem

rem

Tbar

N

e

1

8.41

N

N

e

1

8.41

N

95

ball

95

Tbar

(26)