100

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

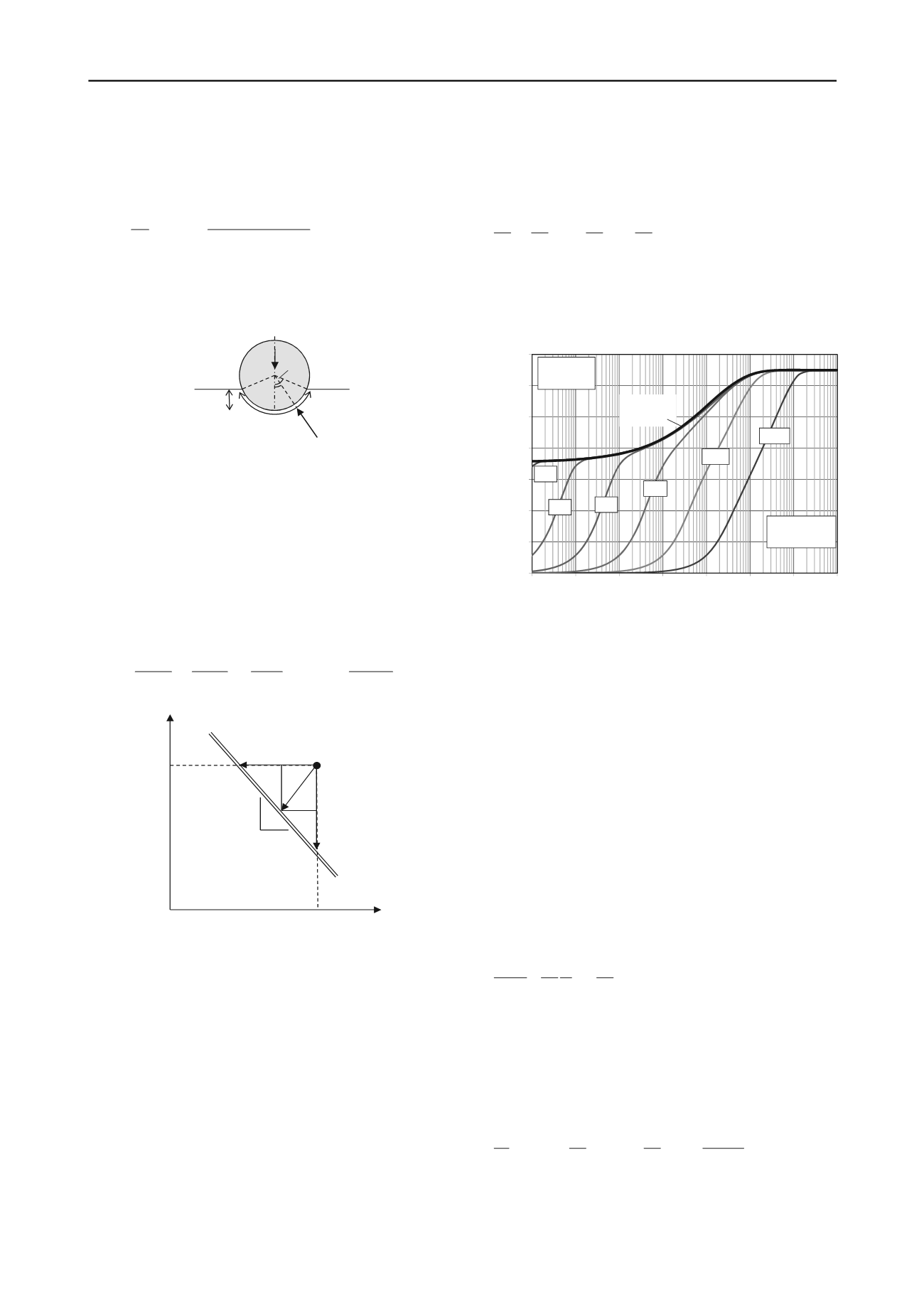

normal effective stresses around the perimeter, P, of the

interface, with S adjusted to balance the submerged pipeline

weight, W', allows the average normal effective stress, q, to be

expressed as

D/2

DP and

1.27

cos

sin

sin2

with

P

W q

m

m m

m

m

(38)

The value of

m

is related to the normalised embedment by

cos

m

= 1 - 2w/D.

Pipe

diameter D

w

m

P

n

' ~ Scos

W'

Figure 22 Schematic of embedded pipe.

Within a conventional critical state framework, the effect of

the time scale for axial movement may be evaluated by

considering the tendency for the adjacent soil to compact, or

dilate, and the resulting maximum (in an absolute sense) excess

pore pressure that may develop during rapid shearing. This is

illustrated in Figure 23 for the case of contractive soil. The

potential maximum reduction in void ratio, -

e

max

, during

drained shearing is equivalent to a state parameter (Been and

Jefferies 1985), although more usefully expressed in terms of

volumetric strain,

v,max

. The corresponding maximum excess

pore pressure during undrained shearing is then obtained from

*

e1

e

q

u

1 ln

max ,v

max ,v

0

max

max

(39)

ln

'

n

e

e

max

q

e

0

u

max

u

e

critical

state line

Figure 23 Critical state framework for stress paths during shearing.

The proportion of

u

max

that develops at the pipeline-soil

interface depends on the velocity and time scale (or cumulative

displacement) of the axial motion. For slow movement, excess

pore pressure can dissipate as fast as it is generated, and the

response is fully drained, while at the opposite extreme high

excess pore pressures are generated initially, although should

dissipate with continued displacement.

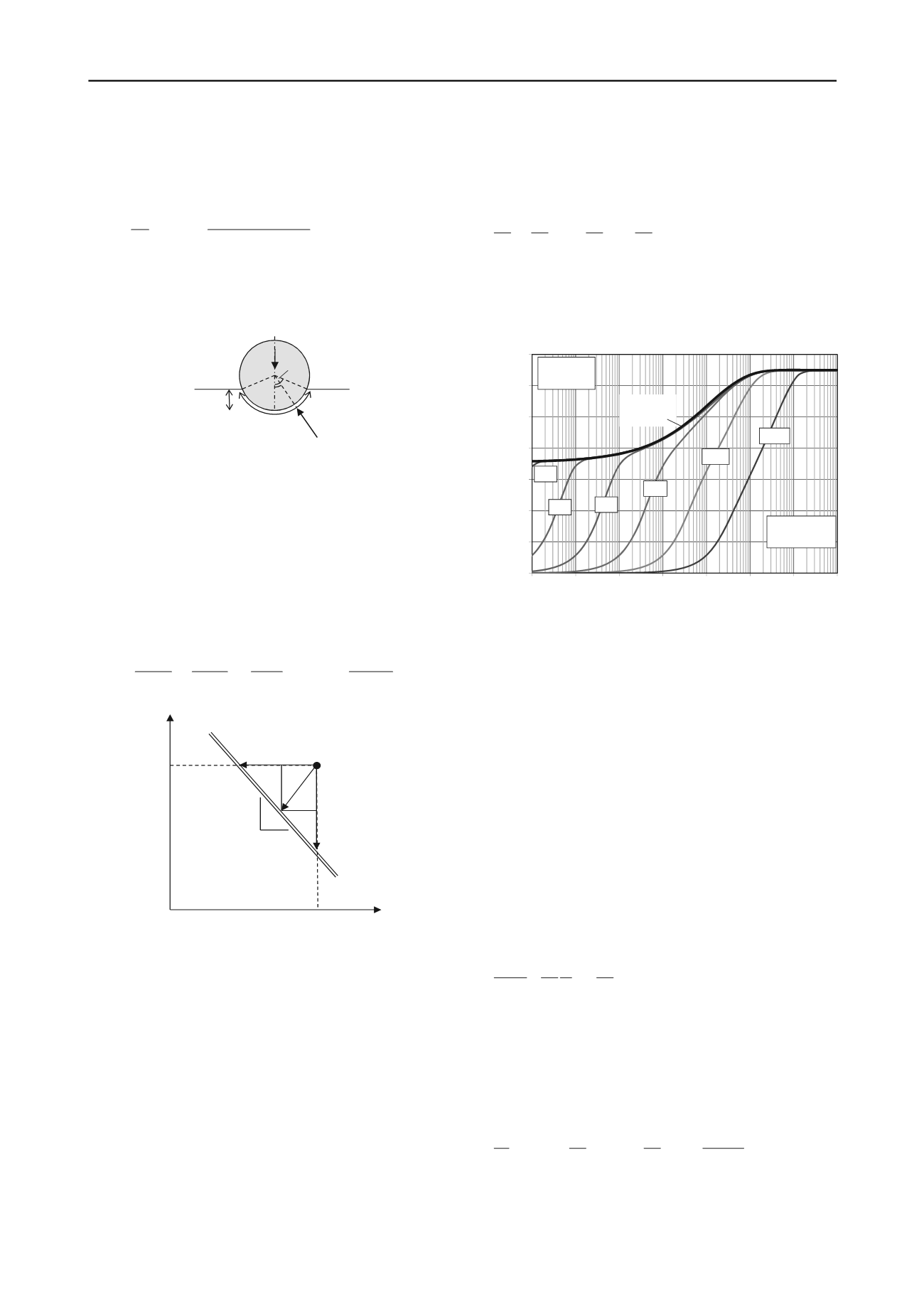

An example response is shown in Figure 24 from FE

analysis of a pipeline resting on normally consolidated Modified

Cam Clay, with a plane strain friction angle of 27 º (Randolph

et al. 2012). The theoretical wedging factor for w/D = 0.4 is

1.25, so that the drained axial friction factor is F/W' ~

1.25tan(27) = 0.64. For fast shearing the initial excess pore

pressure ratio,

u

max

/q, is about 0.45, so that the undrained

friction ratio is (1 – 0.45)×0.64 = 0.35.

With increasing elapsed time, or displacement (noting that

c

v

t/D

2

is equivalent to (

/D)/(vD/c

v

)), the excess pore pressures

dissipate and the friction ratio increases to the drained value.

The form of the backbone curve that quantifies the degree of

consolidation as a function of T = c

v

t/D

2

may be approximated

as (Randolph et al. 2012):

m

50

T/T)2 ln(

u

d

d

e

'W

F

'W

F

'W

F

'W

F

(40)

where the subscripts d and u denote drained and undrained

limits, m ~ 0.5 and T

50

, representing the non-dimensional time

where the friction ratio is midway between drained and

undrained limits, is about 0.05.

0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.00001 0.0001 0.001 0.01 0.1

1

10

100

Mobilised axial friction, F/W'

c

v

t/D

2

Pipe

w/D = 0.4

0.0039

0.039

0.39

3.9

39

390

Values

of vD/c

v

as indicated

Backbone

curve fit

Figure 24 Example axial response of pipeline as a function of non-

dimensional time and velocity.

Unfortunately, data from extensive model tests on pipe

segments are not consistent with the theoretical framework of

critical state soil mechanics and consolidation described above.

The data show that excess pore pressures may be regenerated

during fast axial motion that follows slow, drained, axial

displacement, and indeed the axial friction has generally been

considered as a function of the shearing velocity rather than the

elapsed time during a given motion (White et al. 2011).

A model that broadly reproduces the trends observed in the

model tests was suggested by Randolph et al. (2012). The

model supposes that pore pressure is continuously generated

during shearing, in response to volumetric collapse (generically

referred to as ‘damage’) within the soil adjacent to the pipe. The

rate of (potential) volumetric strain was assumed proportional to

the shear strain rate (denoted by normalised velocity, v/D) and

to the current normal effective stress, so that no further damage

would occur if the effective stress were to fall to zero. Taking

the rate of volumetric collapse (or damage) as

v/D, the rate of

excess pore pressure generation becomes

q

u 1

D

v

*

q

dt /du

(41)

At high rates of shearing, the effect of damage is partially

compensated by slight enhancement of the effective friction

ratio due to increased shear strain rates. This may be modelled

using standard models for rate dependency of shear strength, for

example a form of Herschel-Bulkley relationship, so that the

failure shear stress ratio becomes

D/

v

D/v

1

q

u 1

q

u 1

q

ref

y

HB

f

(42)