109

Honour Lectures /

Conférences honorifiques

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

That is to say we have a P

target

% degree of confidence that μ

p

lies in the range μ

g

(1+or-∆). We can rewrite Eq.3 as

target

p

g

g

P

P

(4)

If the coefficient of variation of the population is δ, then we

assume that the coefficient of variation of the group is also δ.

p

g

p

g

(5)

Combining Eq.2, 4, and 5 we get.

2

2

, 1

, 1

2

2

g

g

n

n

t

or n

t

n

(6)

Eq. 6 is solved by iteration since n influences the value of t.

Student t distribution solvers are available on the internet. The

number n represents the number of soil samples to be tested in

order to obtain the value of the modulus within plus or minus

∆% from the exact answer with a P

target

probability of success. If

we assume that a triaxial test sample to obtain a modulus value

has a volume of 10

-3

m

3

, then the number n of samples gives the

volume of soil that must be drilled during the investigation to

satisfy the criterion. The percent volume tested becomes

3

10

s

t

t

V n

V V

(7)

In our example the initial volume was 1000 m

3

, so we can

calculate what percentage of the soil volume should be tested.

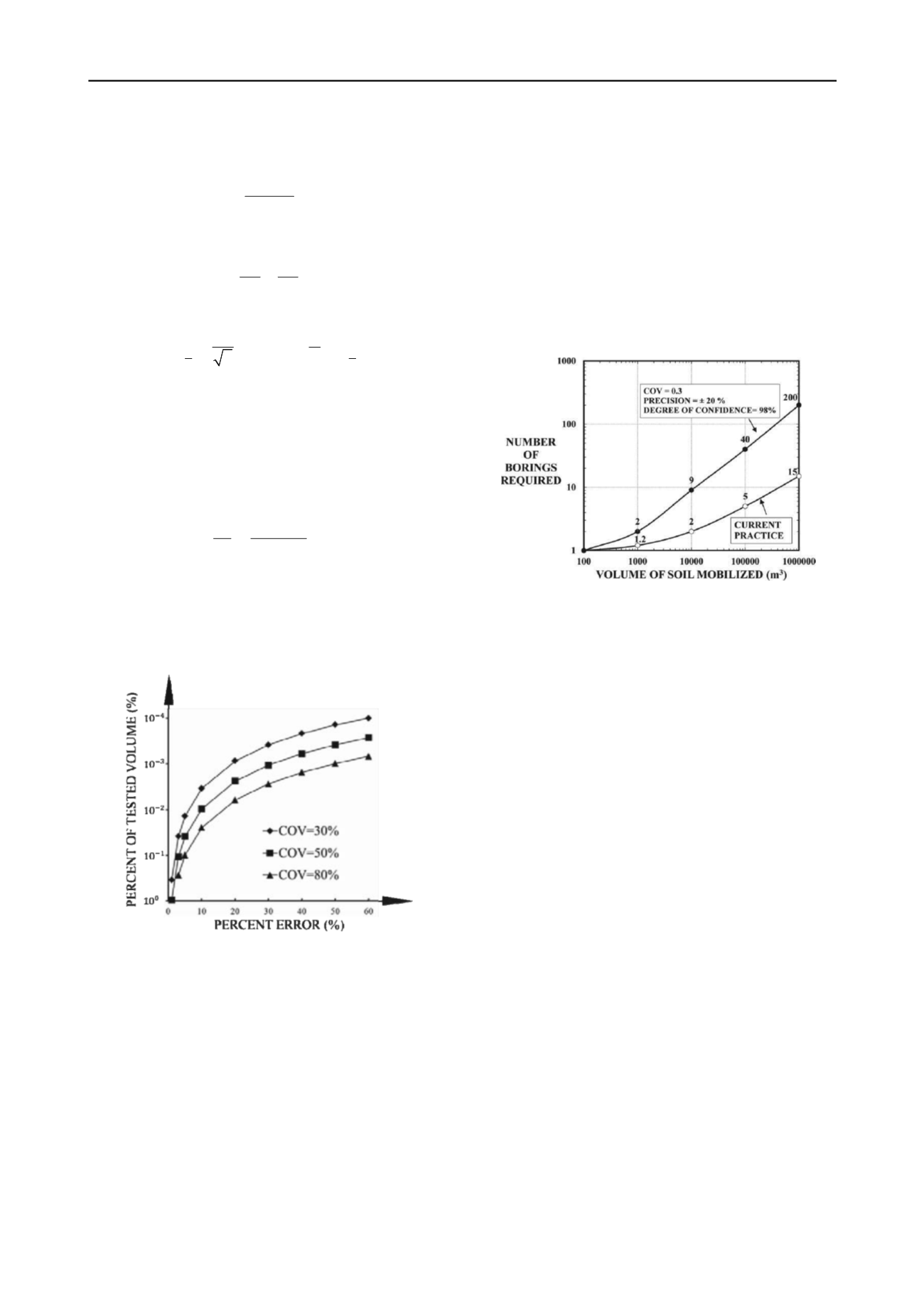

Fig. 4 gives the results and indicates that in order to be 98%

sure that the answer will be within plus or minus 20% from the

true value, the amount of sampling is 0.001 percent of the total

volume.

Figure 4. Required volume of soil to be tested as a percent of

the total volume involved in the soil response to predict a soil

property with a 98% confidence level and within a percent error

for given coefficients of variation of the soil property.

Consider now an 8 story building which is 40 by 40 m at its

base. The volume of soil involved in the response of the

building to loading is at least 40 by 40 by 40 m or 64000 m

3

.

The required sampling is 0.001% or 0.64 m

3

which corresponds

to 640 triaxial tests. Further assuming that we will drill 40 m

deep borings allowing us to conduct 20 triaxial tests per boring,

this would require some 32 borings. In practice, we would

typically drill 4 or 5 borings for such a building. This shows that

we do not test the soil enough in our current soil investigations

to meet the set criterion. Note that the assumptions made in the

student t distribution calculation include the assumption that the

soil is uniformly variable. In other words, there are no

heterogeneity trends or anomalies in the soil mass. If there were

such anomalies, the amount of soil volume to test would

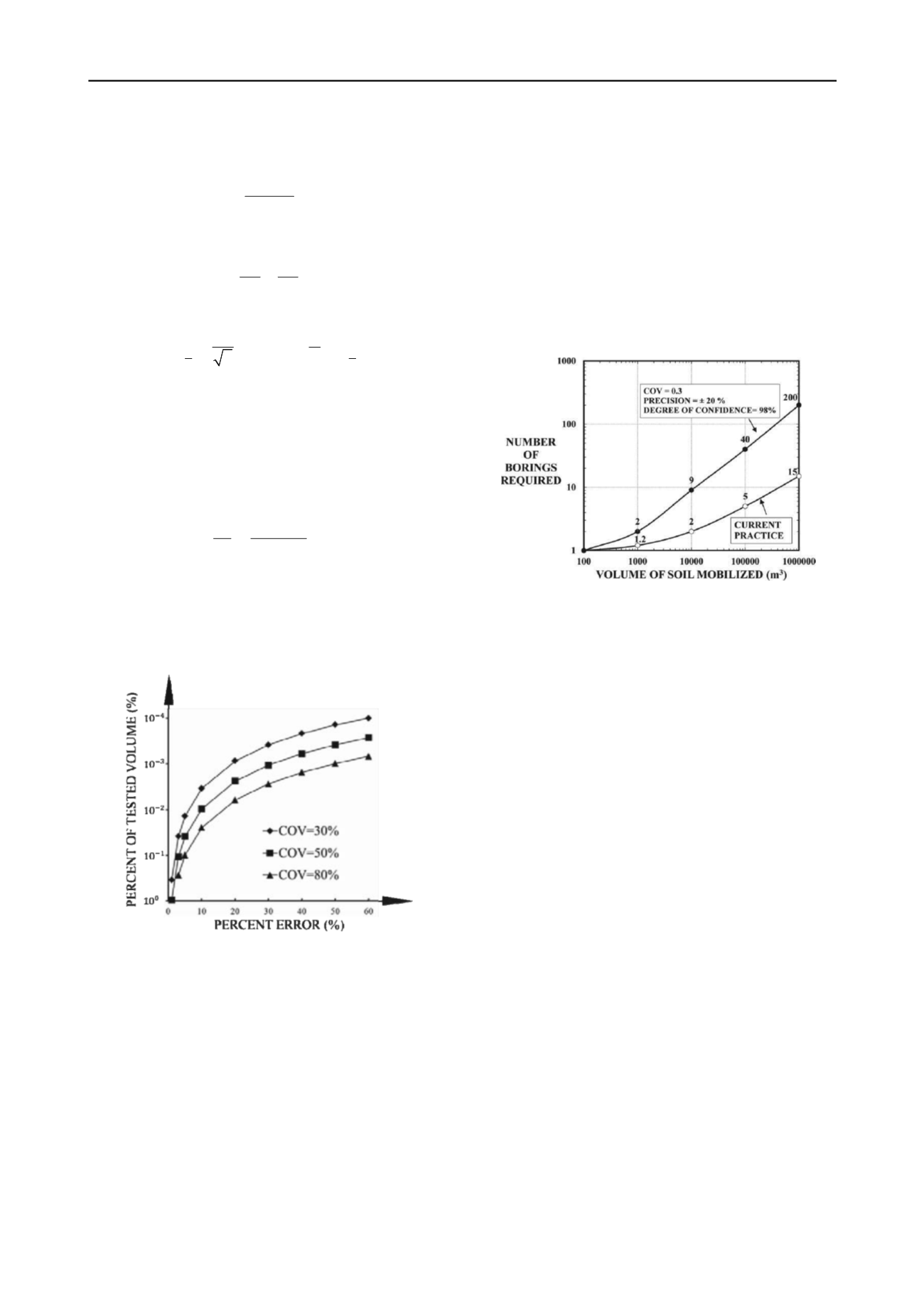

increase. If we use the same approach for different volumes we

can generate the number of borings necessary to meet the

criterion of 98% confidence of predicting within + or – 20% for

a soil with a coefficient of variation equal to 0.3. Fig. 5 shows

the number of borings required as a function of the soil volume

involved in the response to the loading. The estimated line for

current practice is plotted on the same graph (based on the

author’s experience) indicating that current practice does not

meet the criterion established. Note that the discrepancy

increases with the size of the project. Indeed the ratio between

the required number of borings N

r

and the current number of

borings N

c

increases with the size of the imprint.

Figure 5. Comparison of number of borings in current practice

and number of borings required for a precision of + or - 20%

with a 98% degree of confidence for a soil parameter coefficient

of variation of 0.3.

5 WHAT CAN BE IMPROVED ABOUT THE PMT

EQUIPMENT?

Only a few things, I think. We are at the point of maturity in this

area. If anything, we need to be able to run controlled stress

tests or control strain tests equally well. Controlling strain or

volume has the advantage of not having to guess at the limit

pressure to decide on the pressure steps. Controlling pressure

has the advantage of not having to wait for a long time if the

hole is too big. The devices which control stress require

compressed gas bottles which can be dangerous. Control

volume devices are safer in that respect and still allow control

stress tests. Most civil engineering structures apply stress

control steps.

With regard to the issue of the three cells versus mono-cell

probes, it has been shown (Briaud, 1992) that for probes with a

length to diameter ratio longer than 6, the difference between

the expansion of the mono-cell and the expansion of an

infinitely long cylinder for an elastic soil are within 5 % of each

other. Therefore as long as the probe has a length to diameter

ratio of 6 or more, there is no need for three cells in a

pressuremeter probe.

The diameter of the probe has an impact on the quality of the

test for the following reason. The thickness of the ring of

disturbed soil created by the carving or washing process during

drilling is approximately constant regardless of the diameter of

the drill bit. As such, the larger the pressuremeter diameter is,

the less influence this disturbed zone will have on the

pressuremeter curve. Therefore, it is best to increase the

diameter of the pressuremeter probe. A larger diameter will also

have a positive impact on the reliability of the borehole

diameter as it is much easier to drill a well calibrated 150mm

diameter hole than a 50mm diameter hole. Using lightweight yet

rugged 150 mm diameter, 1 m long PMT probes will improve

PMT test quality.