114

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

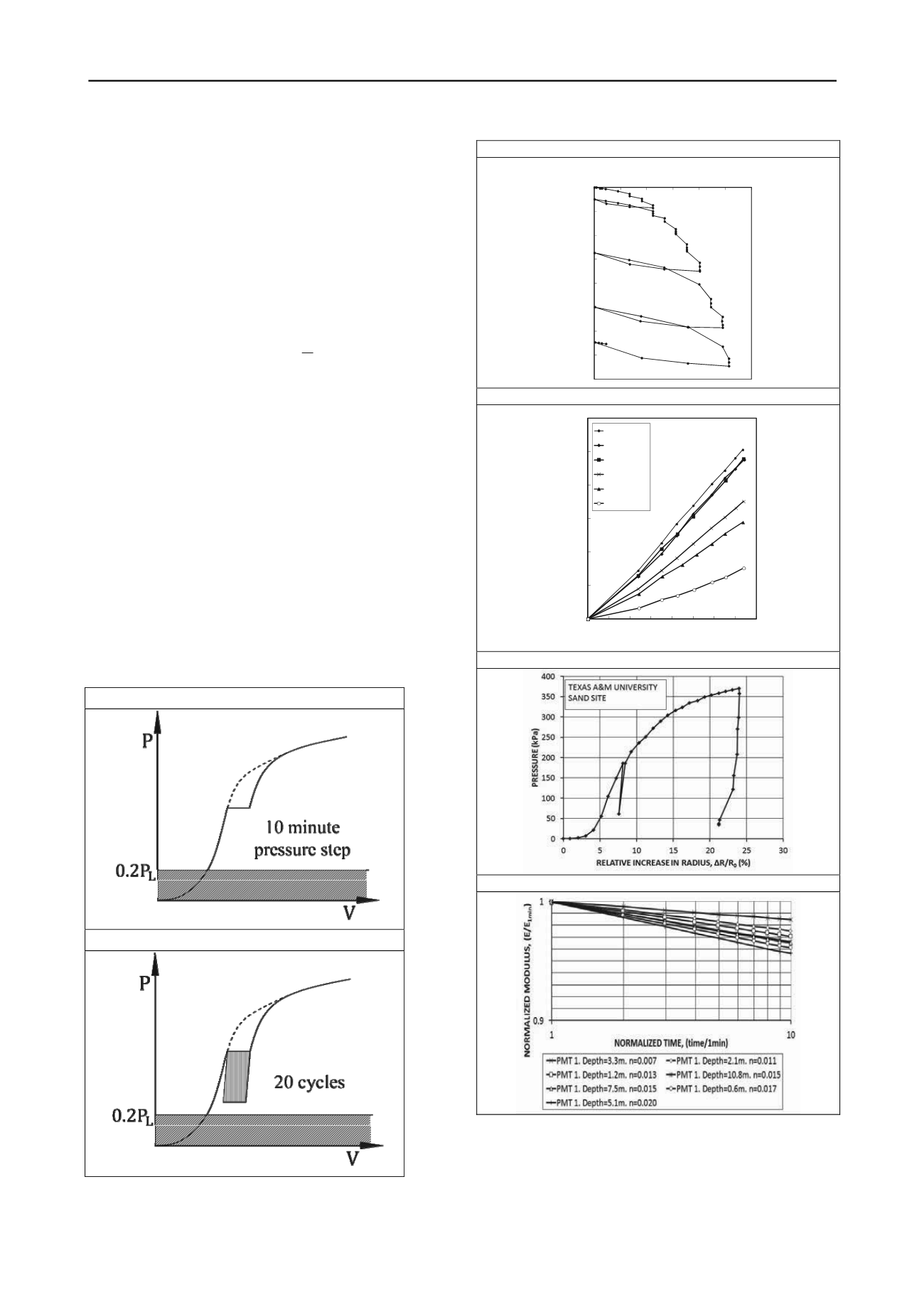

7.4 PMT modulus long term creep, and cyclic loading

It is relatively easy to maintain the pressure constant during a

PMT test while recording the increase in radius of the cavity

(Fig. 12). A pressure holding step of 10 minutes is not very time

consuming and can lead to very valuable information if the

structure will be subjected to long term loading (e.g.: building,

retaining wall). The pressure held for 10 minutes should be

higher than 0.2p

L

because below that threshold the influence of

the decompression-recompression effect and the disturbance

effect is more pronounced (Briaud, 1992). The evolution of the

secant modulus E

t

during the pressure holding test is well

described by the following model:

o

n

t

t

o

t

E E

t

(37)

Where t is the time after the start of the pressure holding step, t

o

is a reference time after the start of the pressure holding step

usually taken as 1 minute, E

t

and E

to

are the secant modulus

corresponding to t and t

o

respectively, and n is the creep

exponent. The value of n is obtained as the slope of the plot of

log E

t

/E

to

vs. log t/t

o

. The creep exponent n increases with the

stress applied over strength ratio and depends on the soil type

and stress history. It has been found in the range of 0.01 to 0.03

for sands and in the rnage of 0.03 to 0.08 for clays (Briaud,

1992). For clays, the lower values are for overconsolidated

clays while the higher values are for very soft clays.

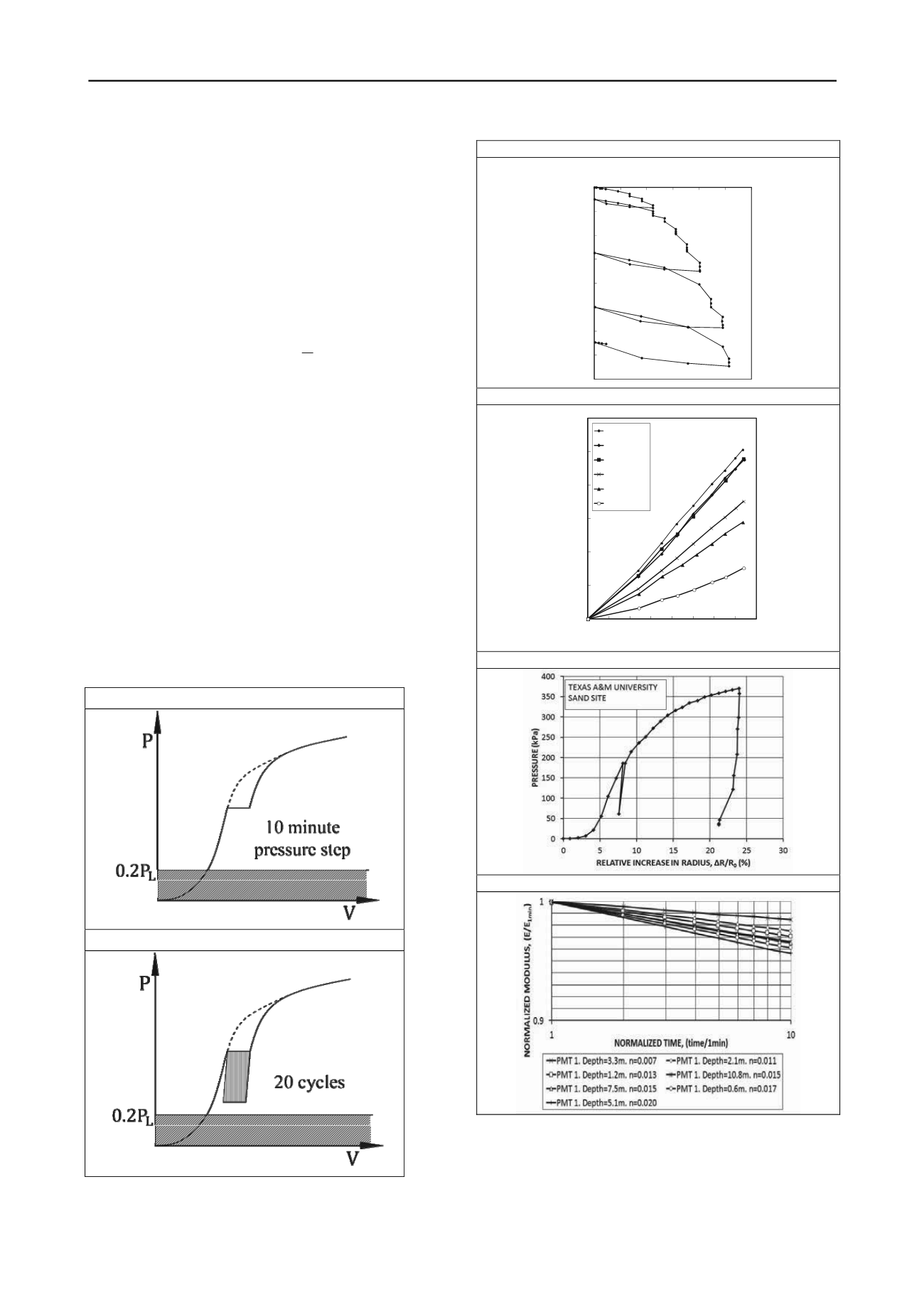

Measurements on large scale spread footings on an unsaturated

silty sand (Briaud, Gibbens, 1999) demonstrated that the power

law model works very well (Fig. 13) because the log settlement

vs. log time curve was remarkably linear. These experiments

also indicated that n increases with the load level but is

significantly reduced by unload reload cycles. PMT tests with

creep steps were performed next to the footings (Fig. 13c and

13d); the parallel between the footing and the PMT is striking.

a. CREEP TEST

b. CYCLIC TEST

Figure 12. Creep and cyclic PMT test

a. FOOTING LOAD-SETTLEMENT CURVE

-160

-140

-120

-100

-80

-60

-40

-20

0

0 2 4 6 8 10 12

SETTLEMENT (mm)

LOAD (MN)

b. FOOTING SETTLEMENT VS TIME CURVE

0.00

0.01

0.02

0.03

0.04

0.05

0.06

0.0 0.2 0.4 0.6 0.8 1.0 1.2 1.4 1.6

LOG DISPLACEMENT LOG

10

(S/S

1

)

LOG TIME, LOG

10

(t/t

1

)

6.23 MN

7.12 MN

8.01 MN

8.9 MN

9.79 MN

10.24 MN

c. PMT STRESS VS STRAIN CURVE

d. PMT MODULUS VS TIME CURVE

Figure 13. Creep response of a 3m by 3m spread footing and a

PMT test (Briaud, Gibbens, 1999, Jeanjean, 1995).

Similarly, one can conduct cyclic loading during the PMT

test. A series of 10 cycles is not very time consuming and can

lead to very valuable information if the structure will be