120

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

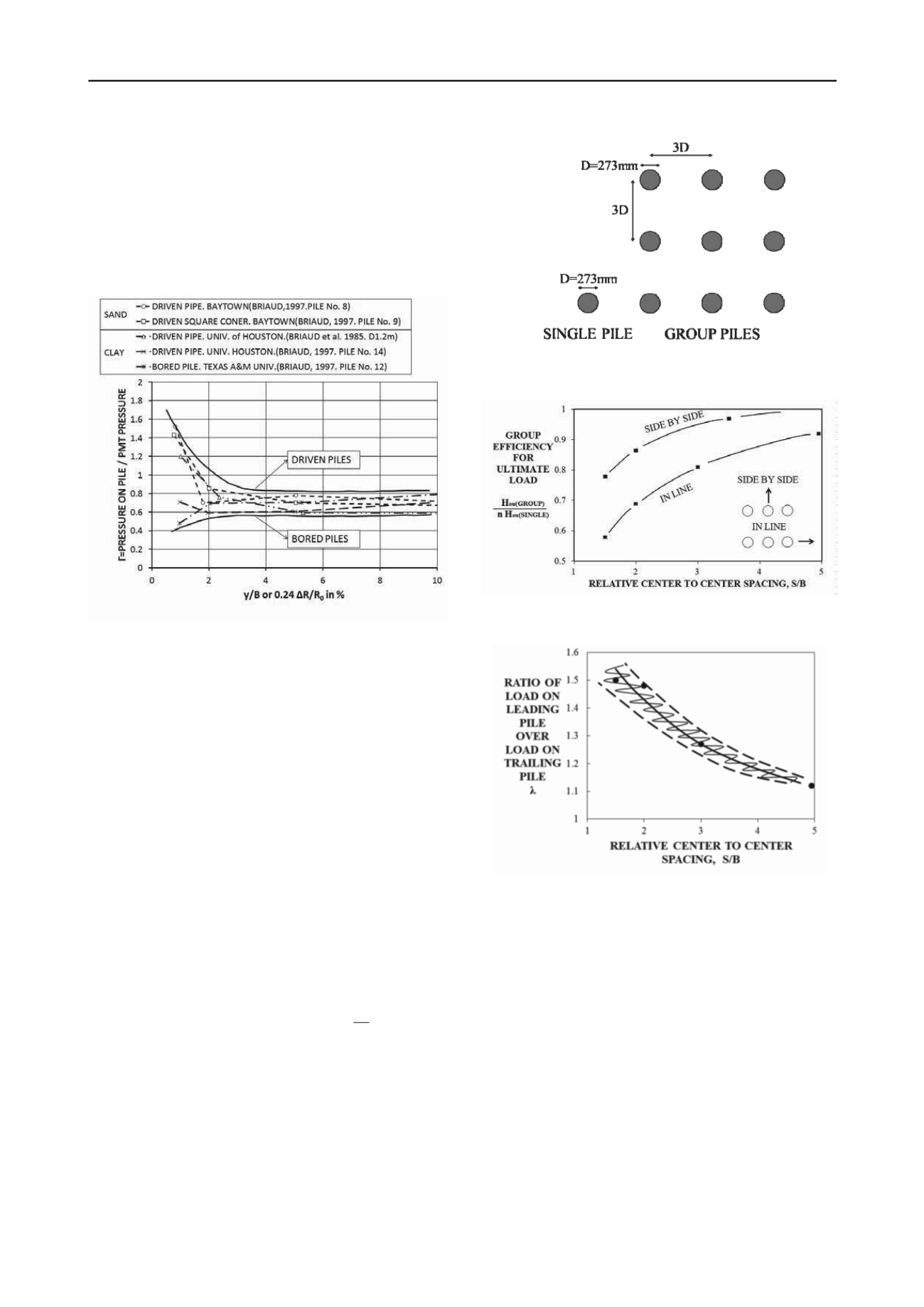

known and the PMT curves were measured at various depths

within the depth D

v

. An average PMT curve was created within

D

v

if more than one test was available. The Γ functions obtained

from these load tests and parallel PMT tests are shown in Fig.

22. They have a shape similar to the one for the shallow

foundations but the pile installation seems to make a difference.

The driven piles lead to one class of Γ functions while the bored

pile leads to a lower function. More data would help refine this

first observation.

Figure 22. The Γ functions for transforming the PMT curve into

a horizontal load – displacement curve for a pile.

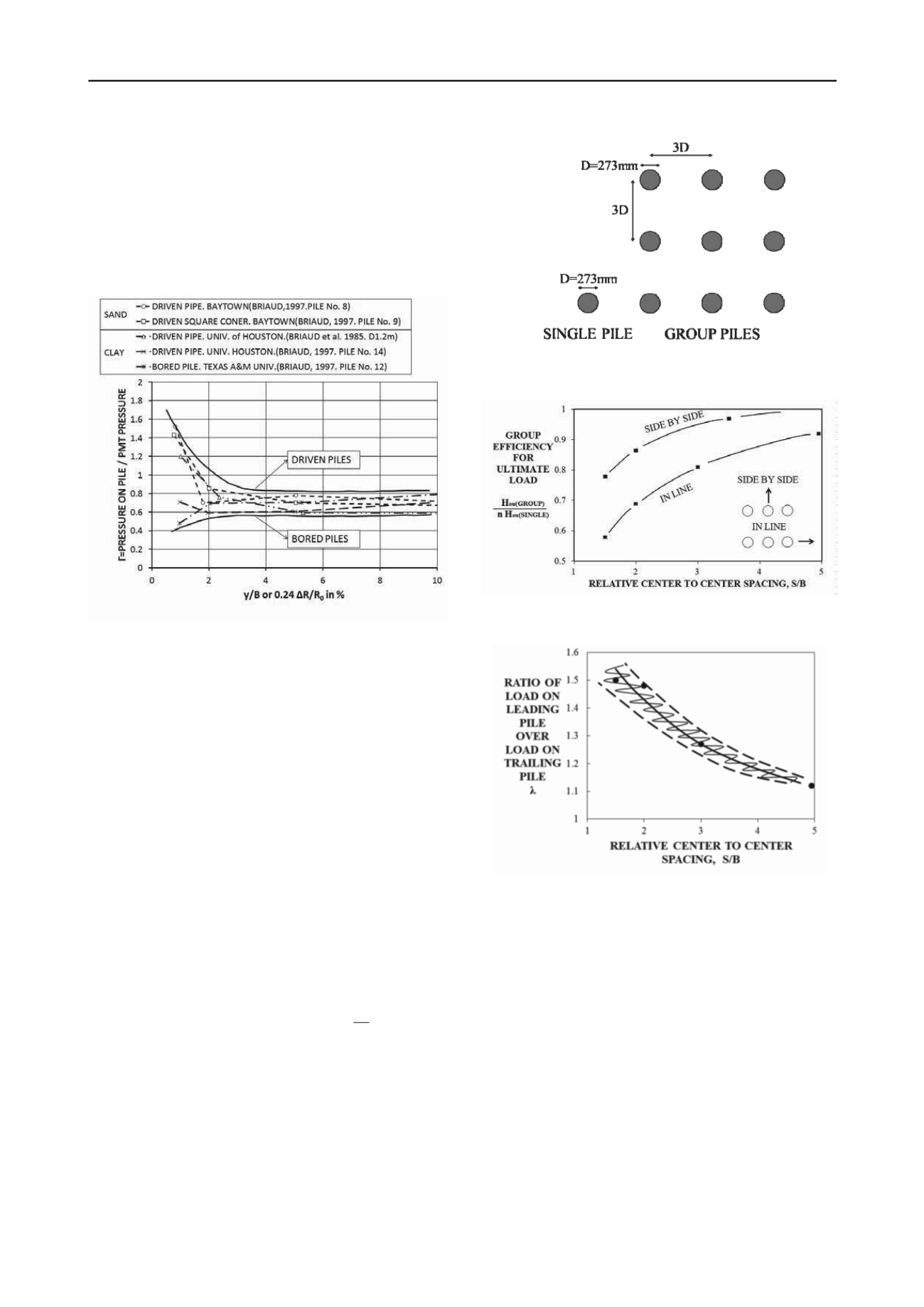

10.2 Pile group behavior

The behavior of vertically loaded pile groups is often predicted

by making use of an efficiency factor of the form

g v s

Q e nQ

(53)

Where Q

g

is the vertical load on the group, e

v

the efficiency of

the vertically loaded group, n the number of piles in the group,

and Q

s

the vertical load on the single pile for the same

settlement as the pile group. This approach can be extended to

the problem of horizontal loading on a pile group by writing

g h s

H e nH

(54)

Where H

g

is the horizontal load on the group, e

h

the efficiency

of the horizontally loaded group, n the number of piles in the

group, and H

s

the horizontal load on the single pile for the same

horizontal movement as the pile group. Fig. 23 shows the plan

view of a group of horizontally loaded piles.

A distinction is made between the leading piles on the front

row of the group and the trailing piles behind the front row.

Using data by Cox et al. (1983), Briaud (2013) proposed to

extend Eq. 54 to read:

(

)

lp

g

lp lp tp tp s

lp lp tp

s

e

H n e n e H n e n H

(55)

Where n

lp

and n

tp

are the number of leading piles and trailing

piles in the group respectively, e

lp

and e

tp

are the efficiency

factors for the leading pile and trailing pile respectively, and λ is

the ratio of e

lp

over e

tp

. Fig. 24 and 25 give the efficiency factors

as a function of the relative pile spacing based on the data by

Cox et al. (1983).

Figure 23. Plan view of a group of horizontally loaded piles.

Figure 24. Leading pile and trailing pile efficiency factors

Figure 25. Ratio of leading over trailing pile efficiency factor

Eq. 52 was developed based on ultimate load observations at

large horizontal displacements. The use of the same equation for

all range of horizontal movements was investigated by

comparing measured and predicted movements for two major

pile group experiments by Brown and Reese (1985) in stiff clay

and by Morrison and Reese (1986) in medium dense sand. The

plan view of the group is shown in Fig.23. The piles were

0.273m in diameter, 13.1m long steel pipe piles driven in a 3 by

3 group with a spacing of 3 diameter center to center. The group

was built to simulate a rigid cap condition which is most

common. The clay was a stiff clay which had an undrained

shear strength of about 100kPa within the top 3 m from the

ground surface. The sand was a medium dense fine sand with a

CPT point resistance increasing from zero at the ground surface

to 3000 kPa at a depth of 2 m. Fig. 26 presents the result for the

test in clay and Fig. 27 for the test in sand. In each case, the

measured load-displacement curve for the single pile is

presented as well as the measured curve linking the average

load per pile in the group and the group displacement. The