95

Honour Lectures /

Conférences honorifiques

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

The quantity,

Tbar

, in Equation (26) reflects the average plastic

shear strain experienced by a typical soil element as it flows

around the T-bar. The corresponding quantity for a ball was

found to be about 10 % lower (

ball

~ 3.3, compared with

Tbar

~ 3.7 – Zhou and Randolph 2009a). Of course, the actual

degree of softening will vary with the original distance of the

soil element from the axis of the advancing penetrometer, since

soil elements immediately adjacent to the penetrometer will

undergo the greatest softening.

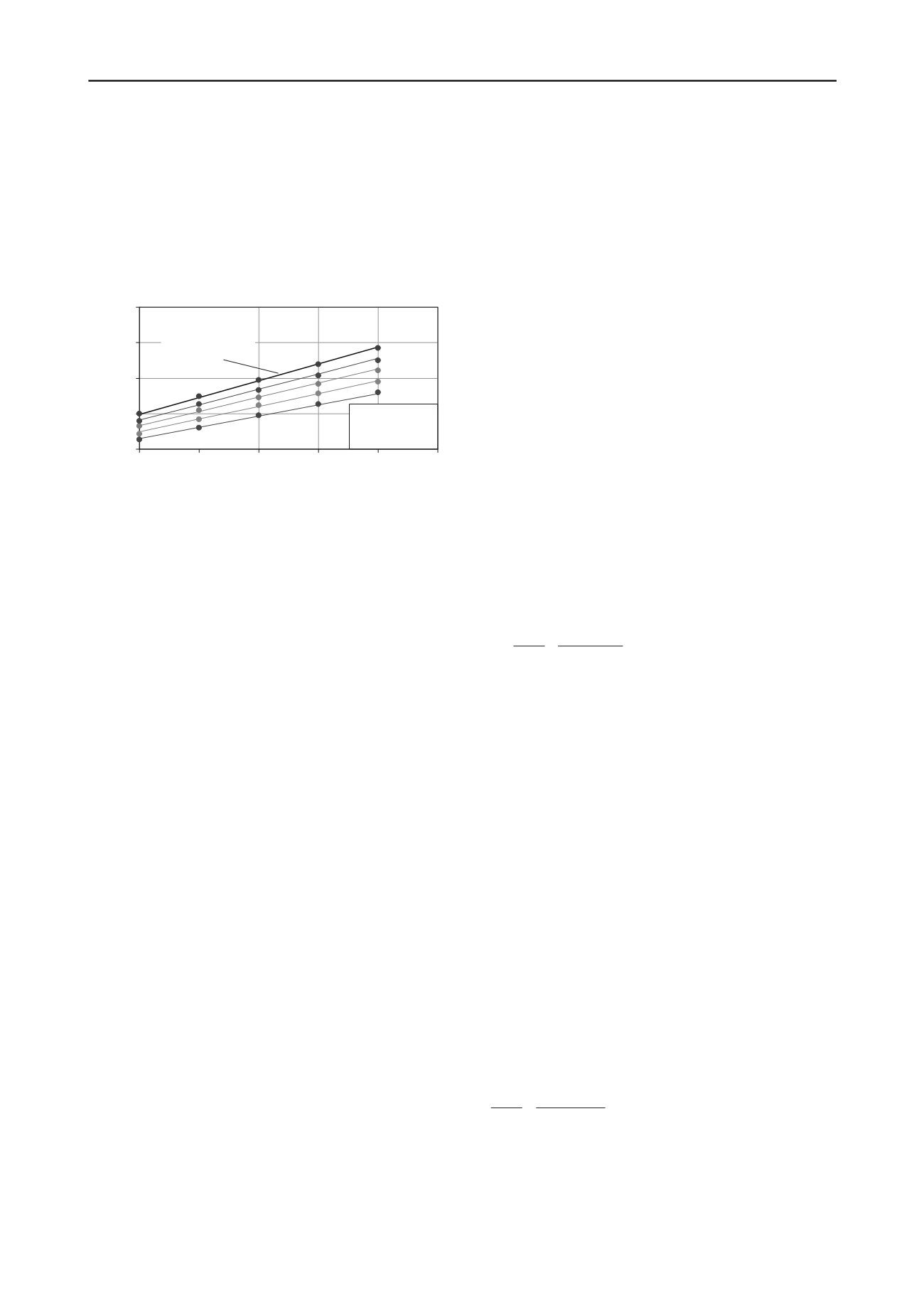

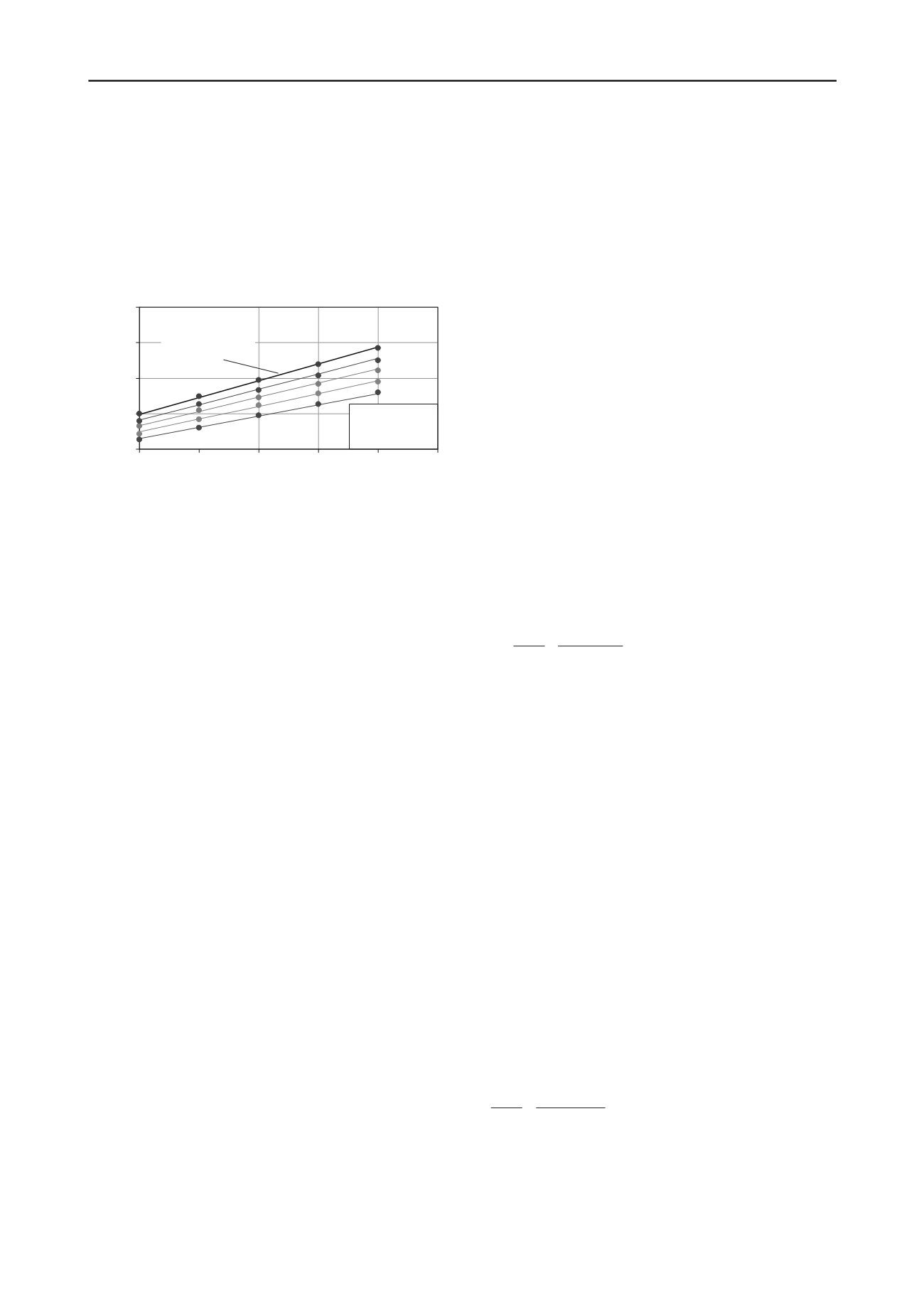

5

10

15

20

25

0

0.05

0.1

0.15

0.2

0.25

Rate parameter

N

Tbar

95

= 50

95

= 25

95

= 15

Parameters

=

rem

= 0.2

Tbar

= 3.7

95

= 10

No strain softening

gradient = 4.8

Figure 11 Values of T-bar resistance factor after allowing for rate

effects and strain softening (sensitivity of S

t

= 5, friction ratio,

= 0.2).

The terms, 1 + 4.8

, in Equation (26) reflect the average

strain rate, which is some 5 orders of magnitude greater than the

nominal ‘laboratory’ reference strain rate of 1 %/hr. This term

should be viewed with some caution, owing to the limitations of

the logarithmic rate law itself, and the inadvisability of trying to

extrapolate over such a large range of strain rates.

Notwithstanding the above reservation, the analytically

derived T-bar and ball factors carry information and should be

made use of during the interpretation of field data. Where both

ball and T-bar penetrometers are used (and similarly for cone

and either T-bar or ball penetrometers), resistance factors

should fall within an appropriate relative range, for example

with N

ball

no more than 10 % greater than N

Tbar

unless the soil

sensitivity exceeds 10.

Low et al. (2010) summarised penetrometer data from a

number of offshore (and some onshore) sites around the world,

recommending global average resistance factors of 11.9 (with

standard deviation of 1.4) for T-bar and ball, relative to an

average or laboratory simple shear strength. A similar value of

12 was proposed for N

Tbar

for low sensitivity clays by DeJong et

al. (2011), although their ball factor was 10 % higher. These

values are plausible, in relation to Figure 11, for example for

soils with a rate dependency factor of

~ 0.1, sensitivity of 3 to

5 and

95

in the range 15 to 25.

Some of the parameters that determine the resistance factors

can be deduced from the tests themselves; thus cyclic tests

enable the sensitivity to be estimated, while tests at different

penetration speeds (best performed at the end of a cyclic test

when the soil strength has stabilised to the remoulded value)

allow the rate parameter to be assessed. The resistance factors

from individual sites summarised by Low et al. (2010) suggest

that for soils of moderate plasticity the T-bar and ball resistance

factors are closer to 11 than 12, while in the ultra-high plasticity

soils off the coast of West Africa the average was around 13.

This suggests higher strain rate dependency of the West African

soils, for example with

closer to 0.15 rather than 0.1.

Higher sensitivity implies low interface friction ratio, as well

as greater loss of strength during passage of the penetrometer.

Numerical analysis for rate dependent (

= 0.1) and softening

(

95

= 15) material, gave ball resistance factors reducing from

21.5 to 11.6 for sensitivities increasing from 1 to 100 (Zhou and

Randolph 2009b). Reducing these by the theoretical ratios for

T-bar and ball resistances for Tresca soil leads to a relationship

for T-bar resistance factors of:

1

t

Tbar

S19~ N

(27)

so ranging from a hypothetical 18 for non-softening soil, to a

lower limit of 9 for ultra-high sensitivity. For typical

sensitivities of offshore sediments in the range of, say, 3 to 10,

the resulting resistance factors would lie between 12 and 9.9.

Values above or below this range imply respectively higher or

lower rate dependency, or sensitivities outside 3 to 10. The form

of variation of resistance factor with soil sensitivity is quite

similar to that observed experimentally by DeJong et al. (2011)

for sensitivities up to about 10, beyond which the experimental

resistance factors (based on field vane strength data) continued

to fall, with a lower limit of around 6.

5.1

Field measurement of consolidation coefficient

The consolidation characteristics of seabed sediments determine

the time scale of consolidation following foundation

installation, or after cyclic loading that may have caused partial

liquefaction. They also determine whether continuous motion,

such as a penetrometer test or the axial and lateral movement of

a pipeline during thermal buckling, occurs in a drained or

undrained manner. It is therefore important to measure the

consolidation coefficient, c

v

, either from laboratory testing or

from field dissipation tests following piezocone penetration.

Piezocone dissipation tests are commonly interpreted by

fitting the excess pore pressure decay to the numerically

determined consolidation solution of Teh and Houlsby (1991).

This may be approximated (as in Equation (1)) as

b

50

ref

T/T1

1

~

u

u U

(28)

where

u

ref

is the reference excess pore pressure that

corresponds (ideally) to the initial excess pore pressure at the

moment where the piezocone penetration ceases. Time t is

normalised as T = c

v

t/d

cone

2

, and T

50

is the normalised time for

50 % excess pore pressure dissipation. (The notation c

h

is often

used, rather than c

v

, for the consolidation coefficient deduced

from piezocone dissipation tests, to emphasise the primary

direction of pore fluid flow.) As noted earlier, the exponent, b,

is about 0.75, and T

50

may be approximated as 0.061 times the

square root of the rigidity index, I

r

.

Determination of c

v

in this way relies on the penetration

phase to have occurred under undrained conditions, for which it

is necessary know the consolidation coefficient! Some insight

into this circular argument may be obtained by the simple

assumption that pore pressure dissipation is a continuous

process, some of which may occur during the penetration phase,

and the rest of which continues, once the piezocone is halted,

during the (subsequent) dissipation phase. This is a slight

simplification, but it has proved useful in identifying limits on

the reliability of interpreting dissipation tests (DeJong and

Randolph 2012).

Excess pore pressure data from numerical analysis (e.g. Yi et

al. 2012) and experiments (Randolph and Hope 2004, Schneider

et al. 2007), where the piezocone was installed at different rates

to span drained to undrained conditions, can be fitted by

c

50

ref

0p

V/V1

1

~

u

u

(29)

where

u

p0

is the excess pore pressure during the penetration,

which in the field situation would become the initial excess pore

pressure for a dissipation test. The normalised velocity, V, is

defined as V = vd

cone

/c

v

, and V

50

is the normalised velocity at

which

u

p0

is 50 % of the reference ‘undrained’ excess pore