87

Honour Lectures /

Conférences honorifiques

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

(Dutt and Ehlers 2009), and of suction caisson extraction

resistance (Colliat and Colliard 2010).

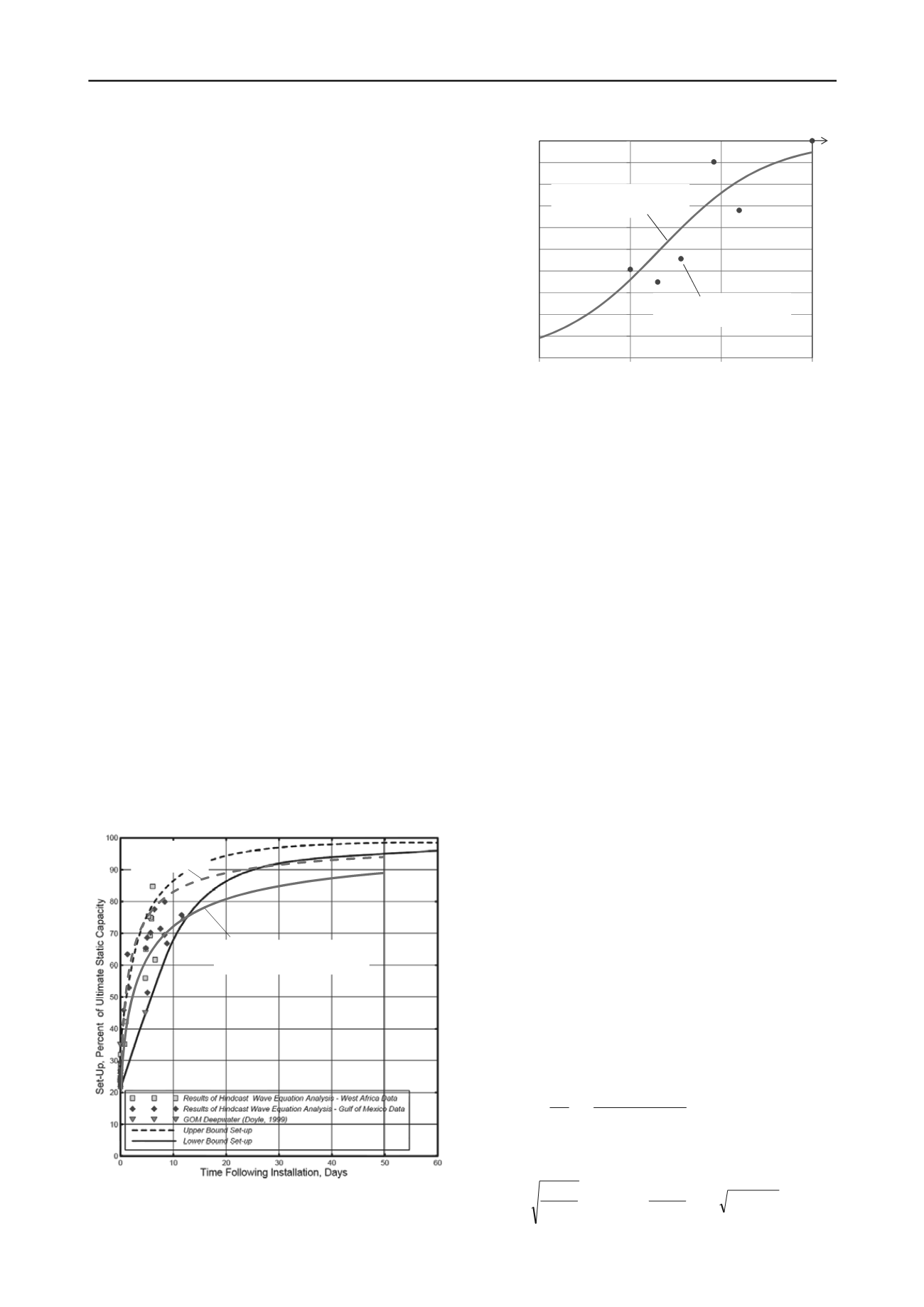

Figure 1 shows a comparison of the radial consolidation

solution with the driving resistance data from Dutt and Ehlers,

taken from sites off the coast of West Africa and in the Gulf of

Mexico. The long term driving resistance was estimated directly

from the API design guidelines, since the longest re-drive delay

was only 8 days (West Africa) to 12 days (Gulf of Mexico). The

data were plotted together, even though the pile diameters

varied between 2.7 m (West Africa, diameter to wall thickness

D/t = 40, so D

eq

= 0.85 m) and 2.1 m (Gulf of Mexico: D/t = 48,

so D

eq

= 0.6 m). The initial driving resistance was around 20 %

of the (estimated) long term resistance, so the analytical

consolidation solution has been adjusted to give a proportion of

long term resistance of 0.2 + 0.8U. The solution matches the

Gulf of Mexico data reasonably, with a plausible consolidation

coefficient of c

v

= 20 m

2

/yr. The data from West Africa do not

show a clear trend, but are mostly bounded by a theoretical

curve for c

v

= 100 m

2

/yr. Although this seems quite high, these

piles were driven to a depth of 150 m, twice the depth of the

Gulf of Mexico piles, and so is reasonable as an upper bound.

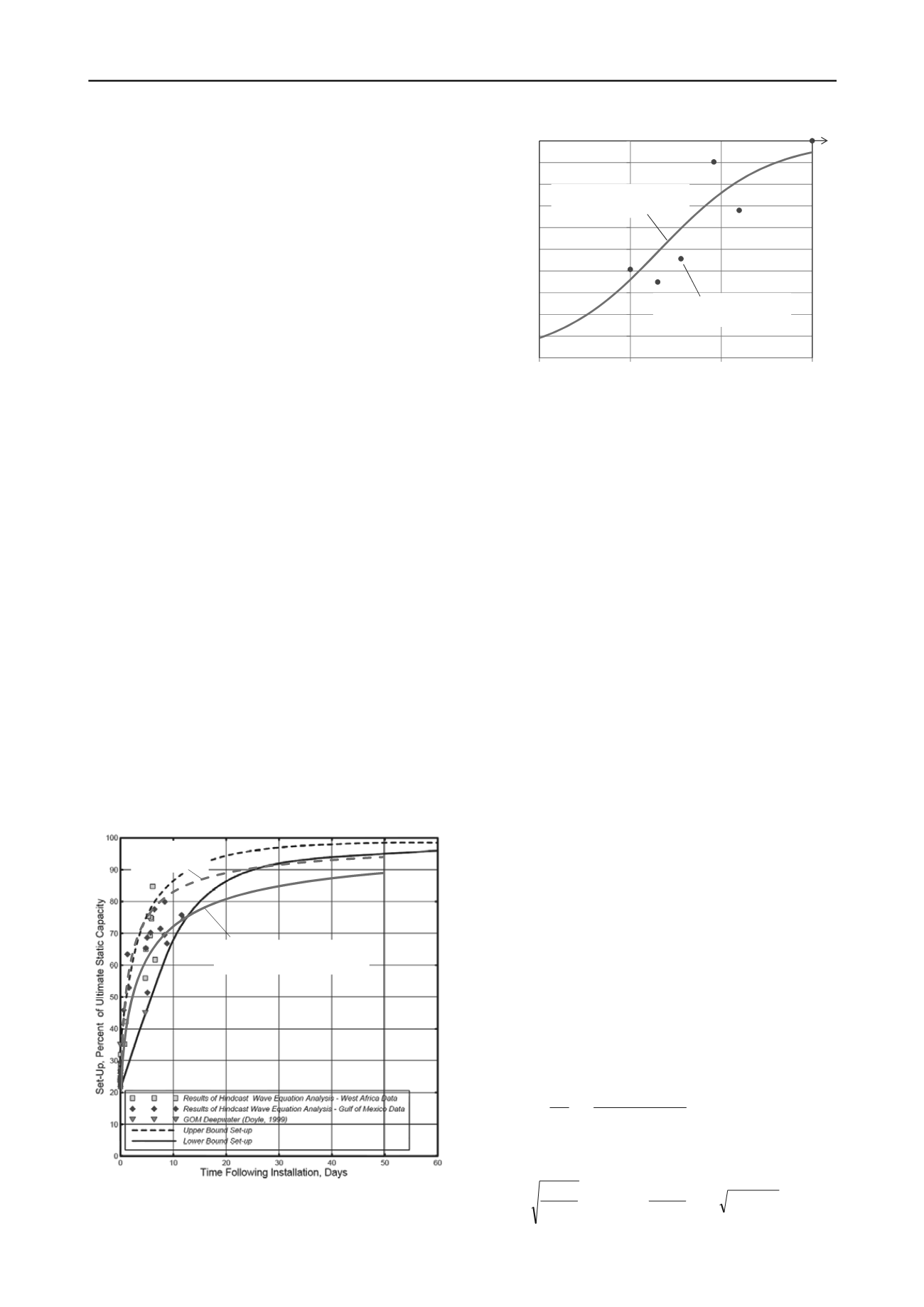

Data from suction caissons from offshore West Africa are

shown in Figure 2. The suction caissons were extracted (by

pumping water into them) at different periods following

installation (Colliat and Colliard 2010). The diameters ranged

between 3.8 and 8 m, and penetration depths from 16.5 to

20.5 m. Although much greater diameter than typical driven

piles, the values of wall thickness were only 20 or 25 mm.

Allowing for only 50 % of the soil displaced being pushed

outwards (Zhou and Randolph 2006), the equivalent diameters

are only 0.28 to 0.45 m.

The relative increase in shaft resistance has been obtained by

normalising by the original shaft resistance. The longest elapsed

time was 1260 days, where the reported shaft resistance was

2.03 times the installation value (the data point is plotted at a

reduced time of 100 days, in order to limit the time axis). All

data points on Figure 2 have been plotted after first scaling the

actual time by (0.3/D

eq

)

2

in order to give a common basis of

comparison. Inevitably there is some scatter in the data, but the

theoretical consolidation curve for c

v

= 10 m

2

/yr (and

D

eq

= 0.3 m) lies within a factor of about 2 for all but one

datapoint. The coefficient of consolidation seems reasonable,

given that the average depth is almost an order of magnitude

lower than for the driven piles in Figure 1.

Radial consolidation solution

(c

v

= 20 m

2

/yr; D

eq

= 0.6 m)

c

v

= 100 m

2

/yr;

D

eff

= 0.85 m

Figure 1 Increase in pile shaft capacity with time following driving

(field data and original figure from Dutt and Ehlers 2009).

0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1

0.1

1

10

100

Relative increase in shaft resistance

Time (days) - scaled for D

eq

= 0.3 m

Radial consolidation solution

(c

v

= 10 m

2

/yr; D

eq

= 0.3 m)

Data from suction anchors

(Colliat & Colliard 2011)

Figure 2 Increase in suction caisson extraction resistance with time

following installation.

The time scale of consolidation reported by Colliat and

Colliard (2010) is similar to that noted by Jeanjean (2006), for

suction caissons with diameters 2.9 to 3.7 m (equivalent

diameters of 0.39 to 0.53 m). Unfortunately, though, the latter

dataset did not include any short term restart or retrieval data,

with the earliest being after a time delay of 50 days (equivalent

to 16 days for D

eq

= 0.3 m). As such, all cases showed relative

increases in excess of 50 %. The average long term (~1000 day)

increase in shaft resistance was only 75 %, compared with

100 % for the West Africa suction caisson data.

It is perhaps disappointing that greater use is not made of

rigorous consolidation analysis in estimating the time scale for

the increase in shaft resistance of piles and suction caissons.

Commentary on the topic is partly obscured by musings on

thixotropy, which may play a role but with no guidance

provided on how to scale from laboratory to field. Ultimately

the shaft resistance results from the increase in normal effective

stress, which is adequately modelled by consolidation analysis.

2.3

Axial load-displacement response

In the offshore industry it is customary to use load transfer

methods to evaluate the axial load-displacement response. Non-

linear load transfer curves allow the full pile response to be

evaluated, from the initial quasi-linear response right up to

failure. It is instructive, though, to consider the form of the load

transfer curves, and elastic solutions for the complete pile that

are applicable at low load levels.

Analytical solutions for axial pile response abound, with

gradually increasing degree of sophistication, starting with

Murff (1975) for the case of a linear load transfer stiffness, k

a

,

uniform with depth. Randolph and Wroth (1978) related the

load transfer stiffness to the soil shear modulus, G, and

extended the solution in an approximate manner to consider a

linear variation of modulus with depth. This was later extended

in a more rigorous manner by Guo and Randolph (1997) for

power law variations of modulus with depth, and by Mylonakis

and Gazetas (1998) for layered profiles, and with allowance for

interaction effects between piles.

The solutions for uniform soil modulus with depth may be

expressed in the generic form of

L tanh KS

L tanh S K

S

w

P

K

b

b

t

t

axial

(3)

with

ap

p

p

a

k EA L

L

EA

S

and L

EA

k

L

(4)