815

Technical Committee 103 /

Comité technique 103

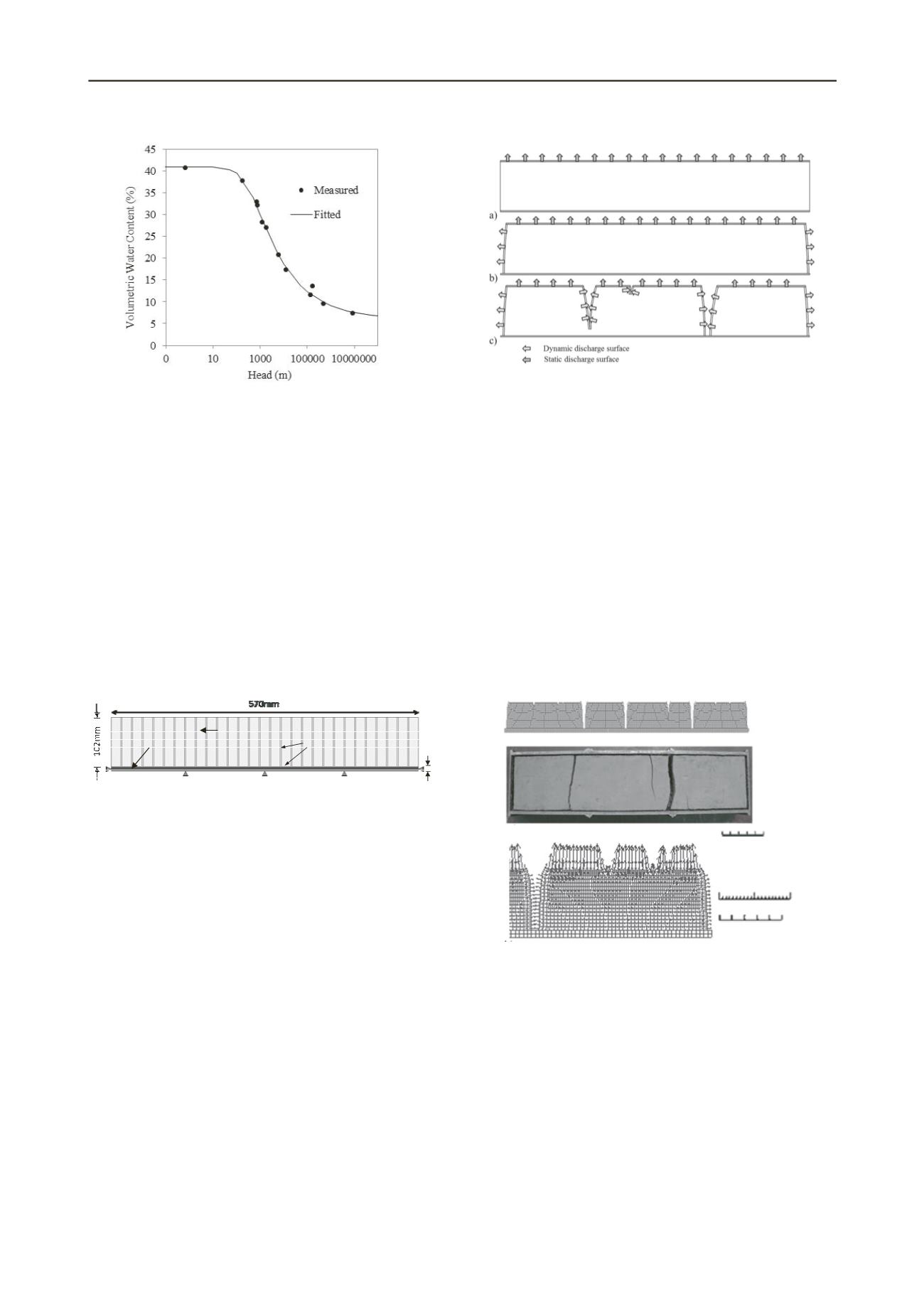

Figure 3 Soil water characteristic curve.

4 NUMERICAL MODEL

The model developed in this work was based on experiments

conducted to investigate the desiccation cracking of compacted

clay fill in the laboratory. As such, the geometry (Figure 4),

material behaviour and initial conditions were based on these

experiments.

The modelled mould consisted of a 190x2 element thick

region located beneath the mesh representing the clay and was

fixed in space. The remaining mesh comprised 190x17

quadrilateral elements, 94 vertically orientated interfaces and 95

horizontal interfaces, the latter forming a single plane between

the base of the clay mesh and the mould. All boundaries of the

sample mesh remained free to shrink/swell in any orientation.

Plane-stress was configured given the finite out-of-plane depth

of the modelled scenario.

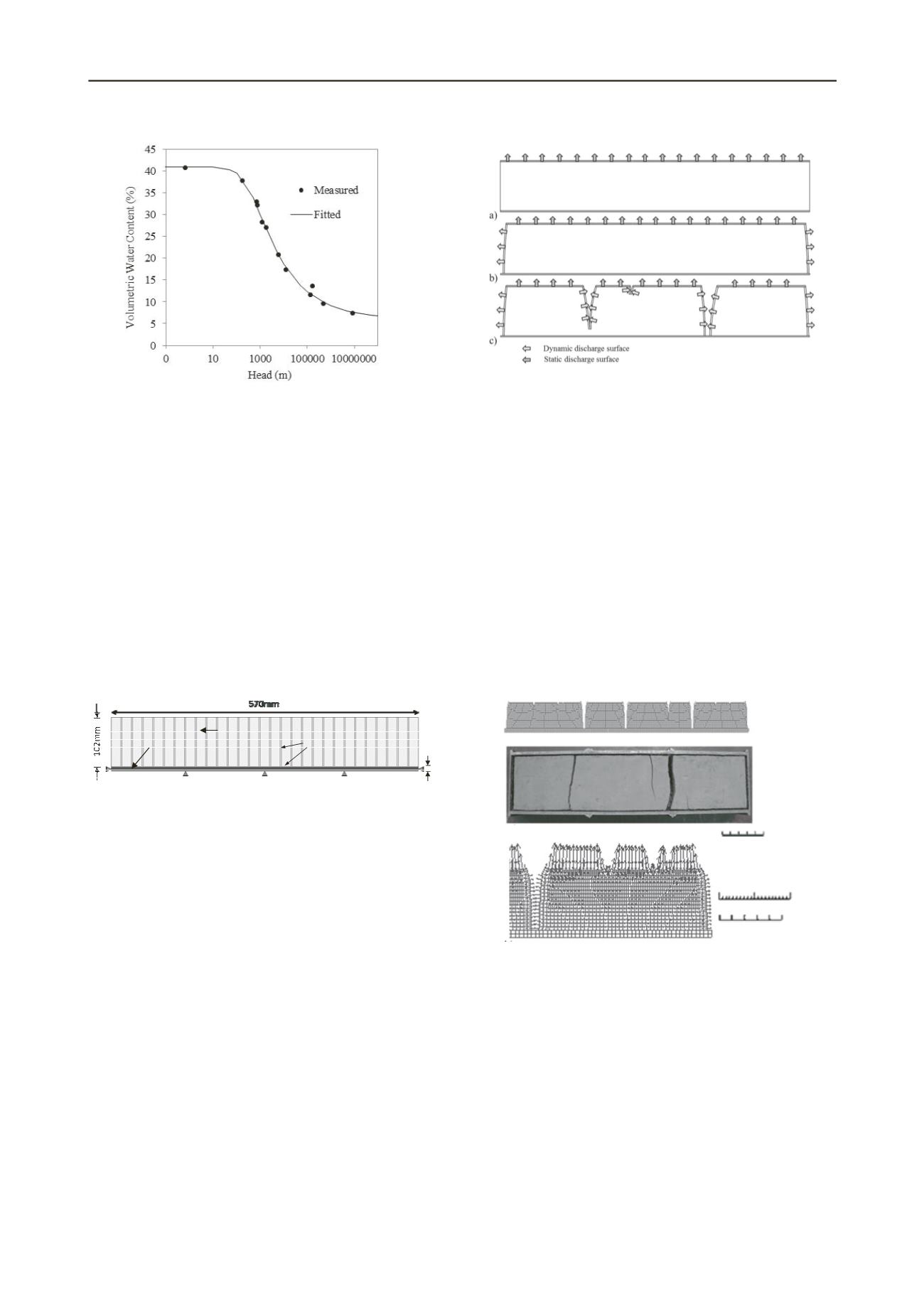

Figure 4 Geometry of the model mesh

n evaporative drying condition was applied to the exposed,

up

e

wa

a drying rate to be applied to the surface,

thi

ace b)

5 RESULTS

An example of the output geometry from a typical

sim

.

A

per surface of the clay. The drying flux was numerically

simulated by application of a discharge boundary condition

statically located at the upper surface of the model mesh (5a).

During the early stages of experimental drying, shrinkag

s observed as both ends of the soil sample, away from the

mould ends resulting in an increase in the exposed surface area

of the sample. Therefore, in addition to simulated discharge

from the upper surface of the sample mesh, the transient

behaviour of the exposed end surfaces was accommodated.

Furthermore, the evaporative surface area increases upon the

onset of cracking and this is also included. At every simulated

hour of drying, each interface is assessed for separation (i.e.

crack opening). When separation is identified, the exposed

‘crack wall’ is subjected to the dynamic discharge condition. An

example evolution of the drying boundary geometry is

illustrated in Figure 5.

The model requires

s was determined from laboratory experiments where mass

loss is considered to be solely that of water.

Figure 5 Illustration of the drying boundaries a) Initial upper surf

Upper surface plus exposed sample ends and c) Upper surface, exposed

ends plus crack walls.

ulation is provided in Figure 6a alongside a representative

laboratory experiment. It can be seen that shrinkage of the

modelled clay has taken place, represented by the difference in

total length between the mesh simulating the clay and that of the

fixed mould. Towards the outer boundaries of the clay mesh, the

edge is seen to curve from the vertical. This realistic behaviour

is captured by the ability of the model to generate the non-linear

negative pore pressure gradient through the depth of the mesh.

By applying a drying condition to the outer surface, primarily

the upper boundary, this region has been found to develop the

greatest suction magnitudes. Additionally, the overall residual

height of the mesh following drying is found to have reduced

from the pre-drying condition.

Figure 6 a) Model geometry output (side elevation) and an inset

example laboratory experiment (plan elevation) and b) Cracked

geometry with flow vectors.

Flow may be seen in Figure 6b to predominantly act in the

upward direction throughout the medium. In the vicinity of

separated interfaces, flow is shown to occur toward the crack

wall contributing to the overall drying mechanism of the model.

The ability to capture the development of tensile stress

throughout the medium is vital for the simulation of crack

initiation and growth conditions. A representative contour plot

of total horizontal stress is presented in Figure 7. Most clearly

depicted is the generation of greatest tensile stress localisation

about the modelled crack tip. As the propagation of interface

separation takes place it is found that the magnitude of this

Flow vectors

Scaled to Max = 1E‐7

Max Vector = 8.045E‐8

0

0

2E‐7

5E‐2m

0

1E‐1m

a)

b)

Interfaces

2mm

Soil

Mould