805

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

1

The design and construction of temporary works for Limerick Immersed Tube

Tunnel

Design et construction des travaux temporaires du tunnel-tube immergé de Limerick

Smith A. K. C.

Coffey Geotechnics Ltd.

Thorup O.

John Sisk & Son Ltd.

Hudson J.

Haydn Evans Consulting, formerly MLM Consulting Ltd.

ABSTRACT: An immersed tube tunnel has been constructed across the River Shannon downstream of Limerick. Enabling works

either side of the river comprised two 130 x 30 m retained excavations. Ground conditions at the site consisted of up to 20 m of soft

alluvial soils overlying thin and intermittent glacial deposits on top of limestone. The excavations were retained by combi-walls of

1420 mm tubes and pairs of sheet piles, with the maximum height between supports being 15 m. During construction of the southern

section, considerable problems were experienced with the installation of the base slab underwater. Radical changes were therefore

made to the already complex construction sequence for the northern section. This required very close cooperation between the

construction team, the geotechnical designers and the structural designers. The aim of this paper is to show how this cooperation was

achieved, thus enabling float-out of the first tunnel unit to take place on programme on 7th September 2008.

RÉSUMÉ : Un tunnel-tube immergé traversant la rivière Shannon a été construit en aval de Limerick. La réalisation des travaux ont

nécessité deux excavations de retenue de 130x30m. Les conditions de sol du chantier consistaient en 20m de sols alluviaux mous

couvrant des dépôts glaciaires minces et intermittents recouverts de calcaire. Les excavations étaient retenues par des combi-murs

faits de tubes de 1420mm et de paires de palplanches avec une hauteur maximale de 15m entre les supports.Pendant la construction de

la section Sud nous avons expérimenté des problèmes considérables quant à l'installation de la dalle de base immergée. Il a donc fallu

engager des changements radicaux dans la construction déjà complexe de la section Nord. Tout ceci a nécessité une étroite

coopération entre l'équipe de construction, les concepteurs géotechniques et les concepteurs structuraux. Le but de cet article est de

montrer comment on a pu parvenir à cette coopération qui nous a permis de placer la première unité du tunnel le 7 Septembre 2008,

comme programmé.

KEYWORDS: Tunnels, excavations, retaining walls, temporary works, alluvial clays

1 INTRODUCTION

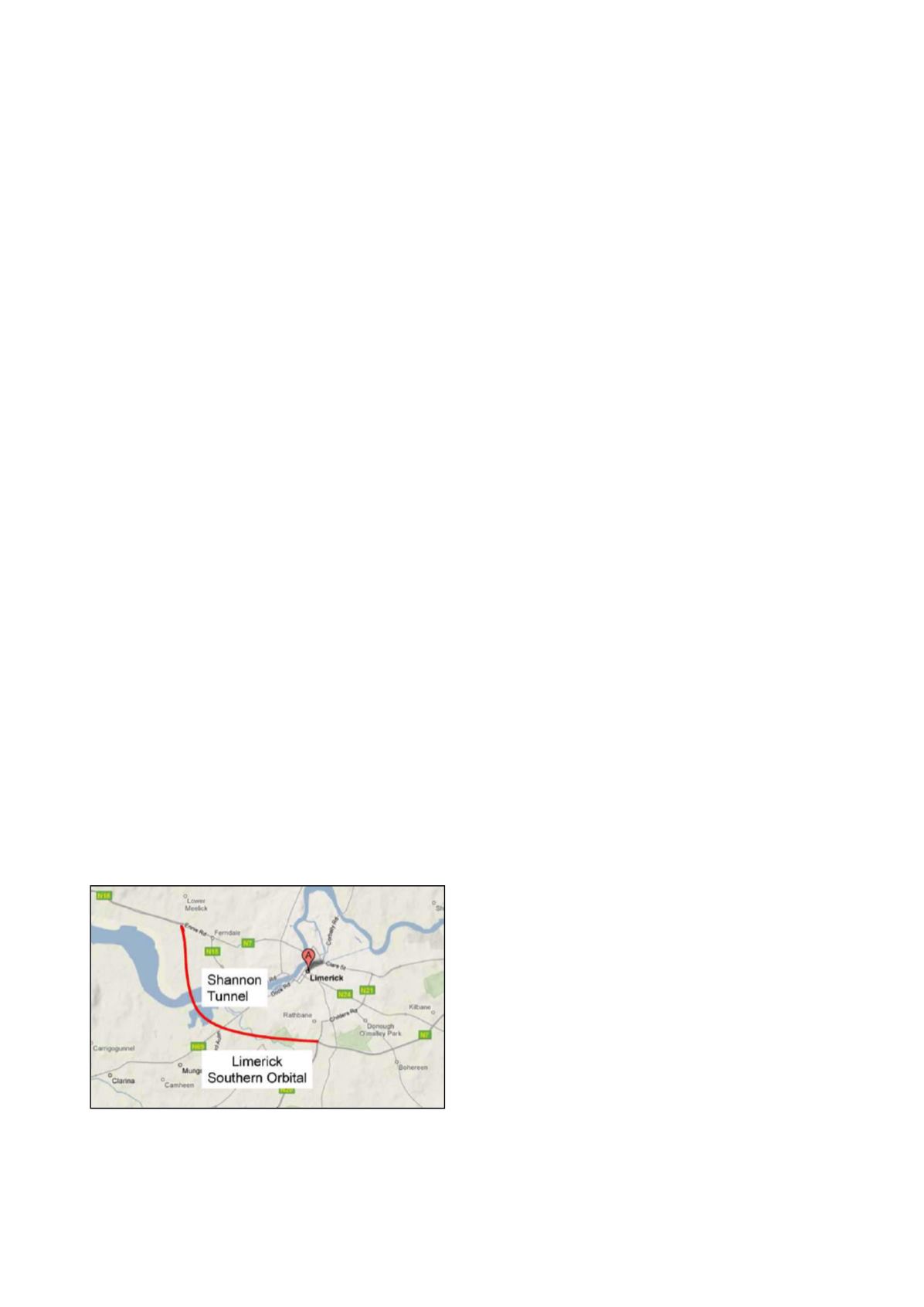

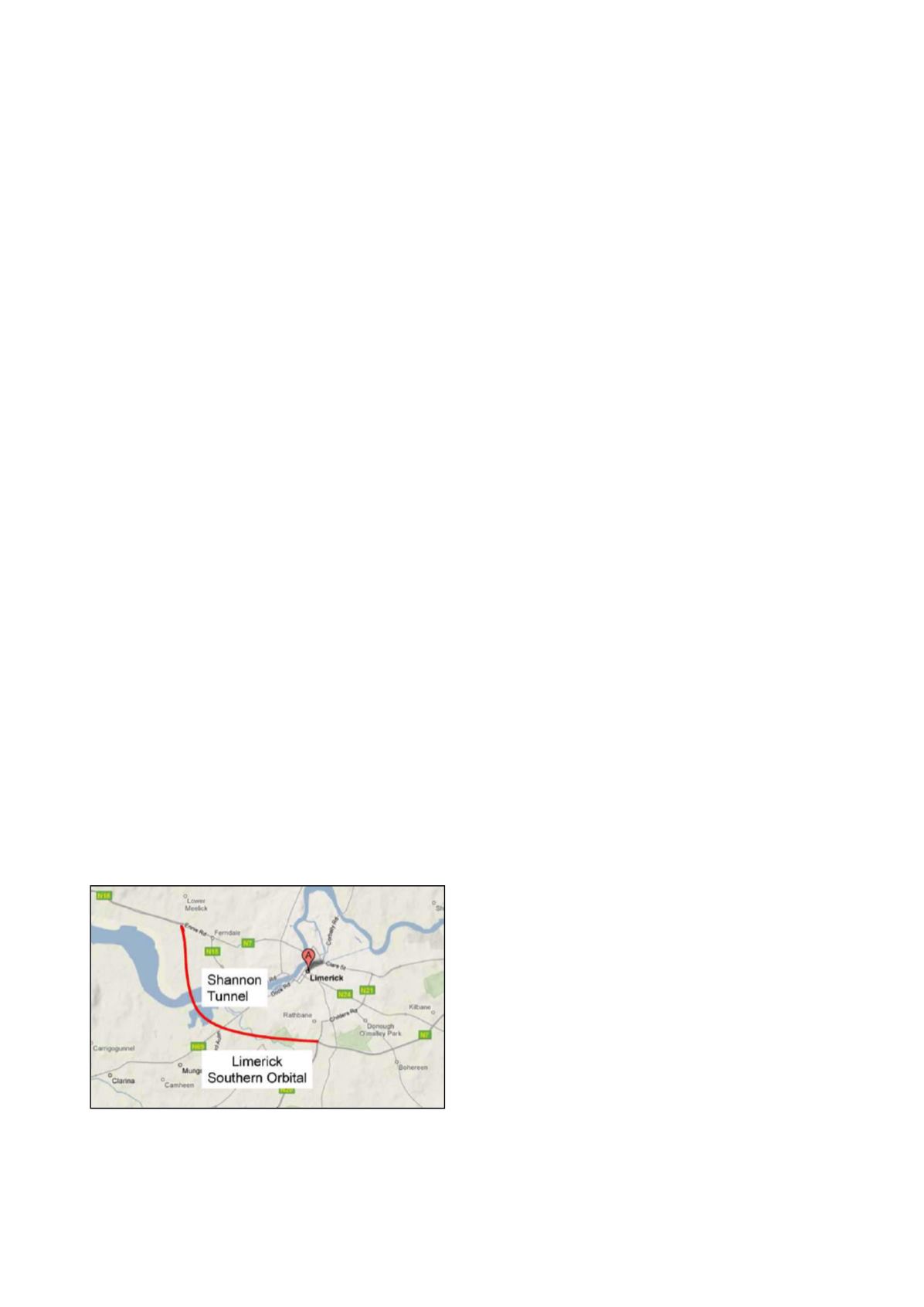

Limerick Immersed Tube Tunnel forms part of the new

Limerick Southern Orbital Road. It crosses the River Shannon

about 3 km downstream of the city centre (Figure 1).

The tunnel is 675 m long, and is formed of five precast units

each 100 m long, 25 m wide and 8 m high, with a cut and cover

section at each end. The units were constructed in an in-line

casting basin on the north side of the river, then floated out

through a temporary retained excavation and sunk in a dredged

trench in the river.

Design and construction were carried out by Direct Route

(Construction) Ltd, a joint venture of John Sisk and Son, Lagan,

Roadbridge and Strabag.

John Sisk and Son were also responsible for the design of the

enabling works for the northern float-out and southern cut and

cover sections, assisted by their consultants Webber Associates

(subsequently Coffey Geotechnics) and MLM Consulting.

2 GROUND CONDITIONS AND SOIL PROPERTIES

A schematic section of the ground along the line of the tunnel is

presented on Figure 2. Ground level is approximately at datum.

On the south side is Bunlicky Lake, an artificial lake created

following excavation by the nearby cement factory. Ground

conditions comprise up to 20 m of soft alluvial clay overlying a

thin and intermittent layer of glacial deposits then

Carboniferous (Visean) Limestone.

Figure 1. Location of tunnel