803

Technical Committee 103 /

Comité technique 103

ij s

f

G

ij

s ijs

2

(21)

DK p p

(22)

ij

ij

f

pH

ij

d

1

(23)

Updated variables are –

(24)

(19b)

ij

ij

ij

p s

ij

d

prev

ij

ij

(25)

4 VISCO-PLASTIC FORMULATION

The loading rate effects due to material viscosity on the

stress-strain behavior of sand (not due to delayed dissipation of

excess pore water) are often very important in geotechnical

engineering practice. A number of researchers (Tatsuoka et al.

2002; Tatsuoka, 2004) reported significant loading rate effects

observed in laboratory stress-strain tests on sand under drained

conditions; i.e., effects of strain rate and its change on the

stress-strain relation, creep deformation and stress-relaxation

during otherwise monotonic loading (ML) at a constant strain

rate.

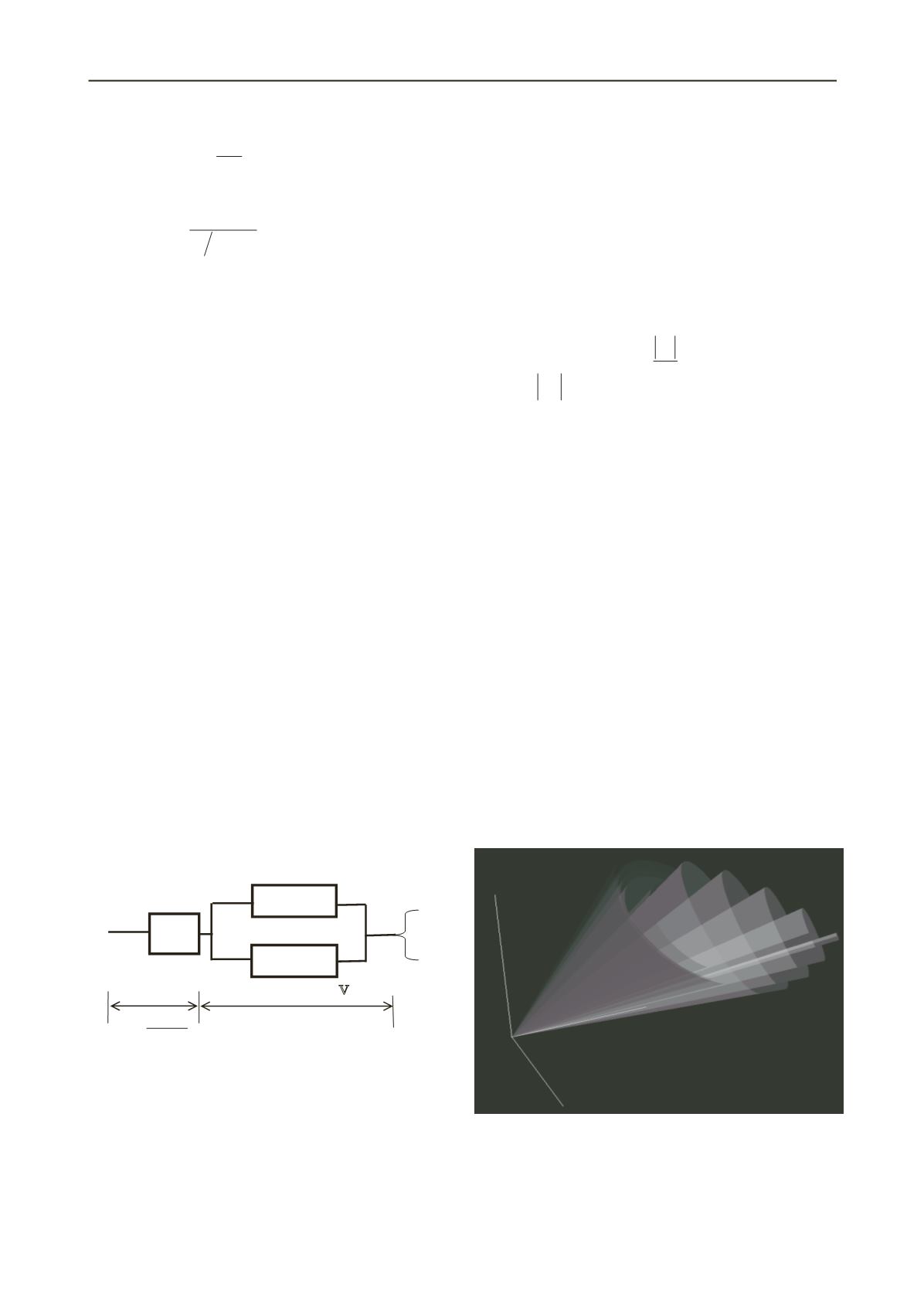

Within the framework of the general non-linear three-

component model (Fig. 1), Di Benedetto et al. (2002) and

Tatsuoka et al. (2002) proposed a set of stress-strain models to

simulate the effects of material viscosity on the stress-strain

behaviour of geomaterial (i.e., clay, sand, gravel and

sedimentary softrock). They showed that the viscous property of

clean sand (i.e., uniform sand) is different from that of clay in

that the viscous effect decays with an increase in the irreversible

strain and proposed a specific model to describe the above (i.e.,

the TESRA model explained below).

In this paper, it is shown that this model can be smoothly

implemented in a FE code (Siddiquee

et al

., 1996, Siddiquee

et

al.,

2006). Then, the shear stress – shear (or axial) strain

relations obtained from typical drained plane strain compression

(PSC) tests performed at fixed confining pressure on clean

sands (i.e., Toyoura and Hostun sands), reported by Di

Benedetto et al. (2002) and Tatsuoka et al. (2002), that were

simulated by the FE code embedded with the TESRA

Temporary Effect of Strain Rate and Acceleration) model are

reported.

σ

EP2

EP1

V

( , ...)

f

ir

( ,

,...)

v ir

ir

( )

e

e

E

1

ir

Figure 1 General non-linear non-linear three-component

model

Although Di Benedetto et al. (2002) and Tatsuoka et al.

(2002) showed at least three different functional forms of the

viscous component,

v

, were proposed. In this paper, the

simplest form (“New Isotach”) was adopted to describe the

loading rate effects of clay-like materials, for which, for

primary ML along a fixed stress path, the current value of

v

is a non-linear function of instantaneous value of

ir

while it is

always proportional to the instantaneous value of

f

as:

,

v ir ir

(

ir

)

f

ir

v

g

(26)

{1

( )}

f

ir

ir

v

g

(27)

where

(

ir g v

)

is the viscosity function, which is always zero

or positive and given as follows for any strain (

ir

) or stress

(

f

) history (with or without cyclic loading):

( )

[1 exp{1 (

1) }] (

ir

ir

m

v

ir

g

r

0)

(28)

where

ir

is the absolute value of

ir

; and

,

r

ir

and

m

are positive material constants. According to this model, as far

as ML continues along a fixed stress path, the viscous stress

component,

v

, is a unique function of instantaneous values of

ir

and

ir

, independent of previous loading history. The

term “new” of the model name comes from that, with the

original isotach model (Suklje, 1966), the stress

(therefore

v

) is a function of instantaneous strain rate,

/

t

,

not

ir

, while, with the new isotach model,

v

is a function

of

ir

. This difference results into significant variations in the

model behaviour, in particular during stress relaxation with

=

0 and immediately after a step change in

during otherwise

ML at a constant

.

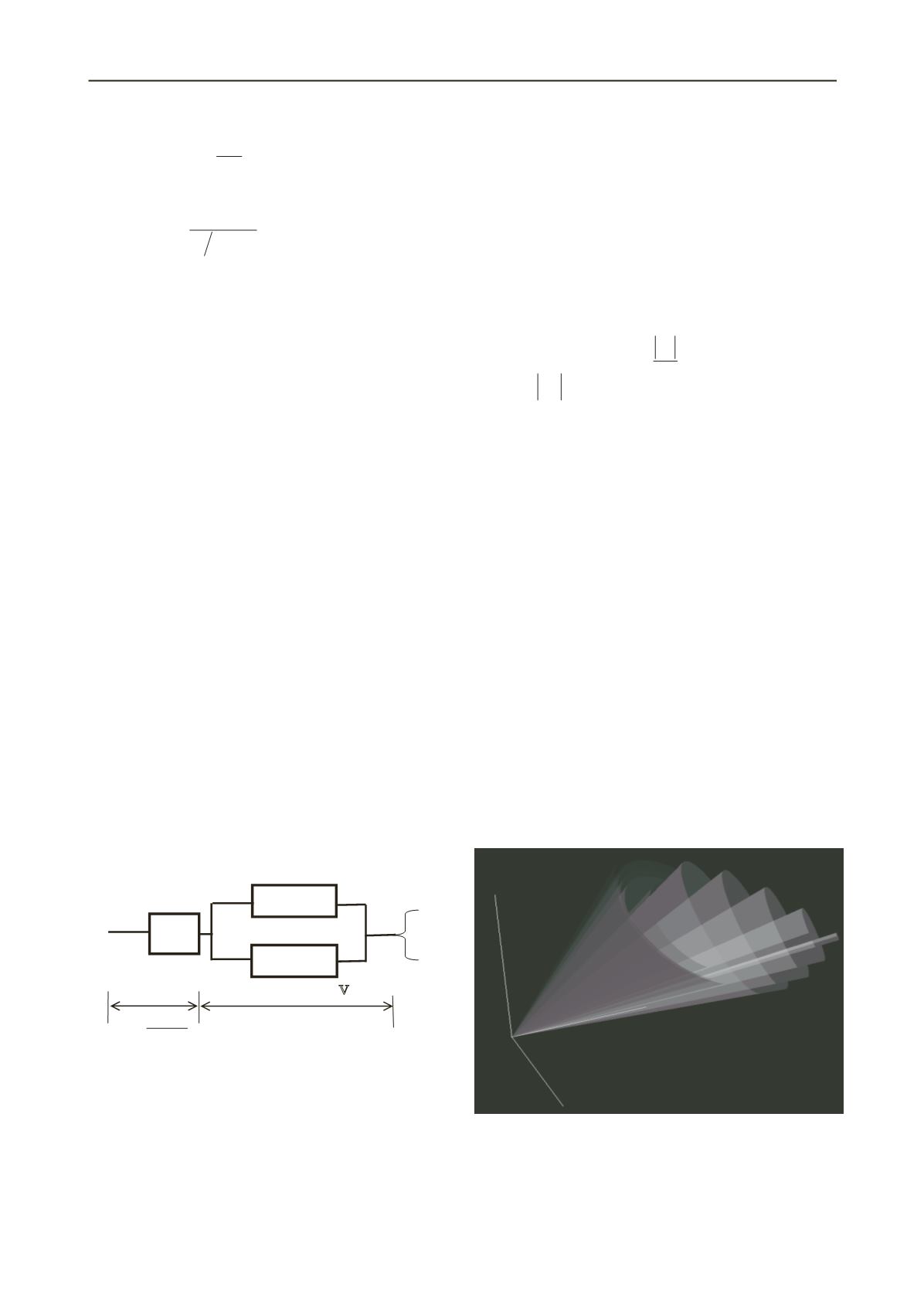

5 IMPLEMENTATION

The model is implemented in one-element FEM with Plane

strain idealization (Siddiquee

et al.,

1999, 2001a, 2001b). The

material data for the initial configuration of the concentric cones

of Drager-Prager yield surfaces (Figure 2) are adopted from the

research work done by Prevost (1985). The viscous property

was set arbitrarily to show the capability of this model by

setting the values of the constants of Eq. (28). Here in this

paper,

=05 and m=0.5 were adopted. The reference value of

loading rate,

r

ir

=1.0e-

8

is set for the analysis. In this paper,

ij

is used instead of

f

in eq. (28) as the model is driven by

the movement of

ij

.

igure 2. Visualization of concentric cones of D ager-Prager

su

F

r

rfaces in Open-GL window.