806

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

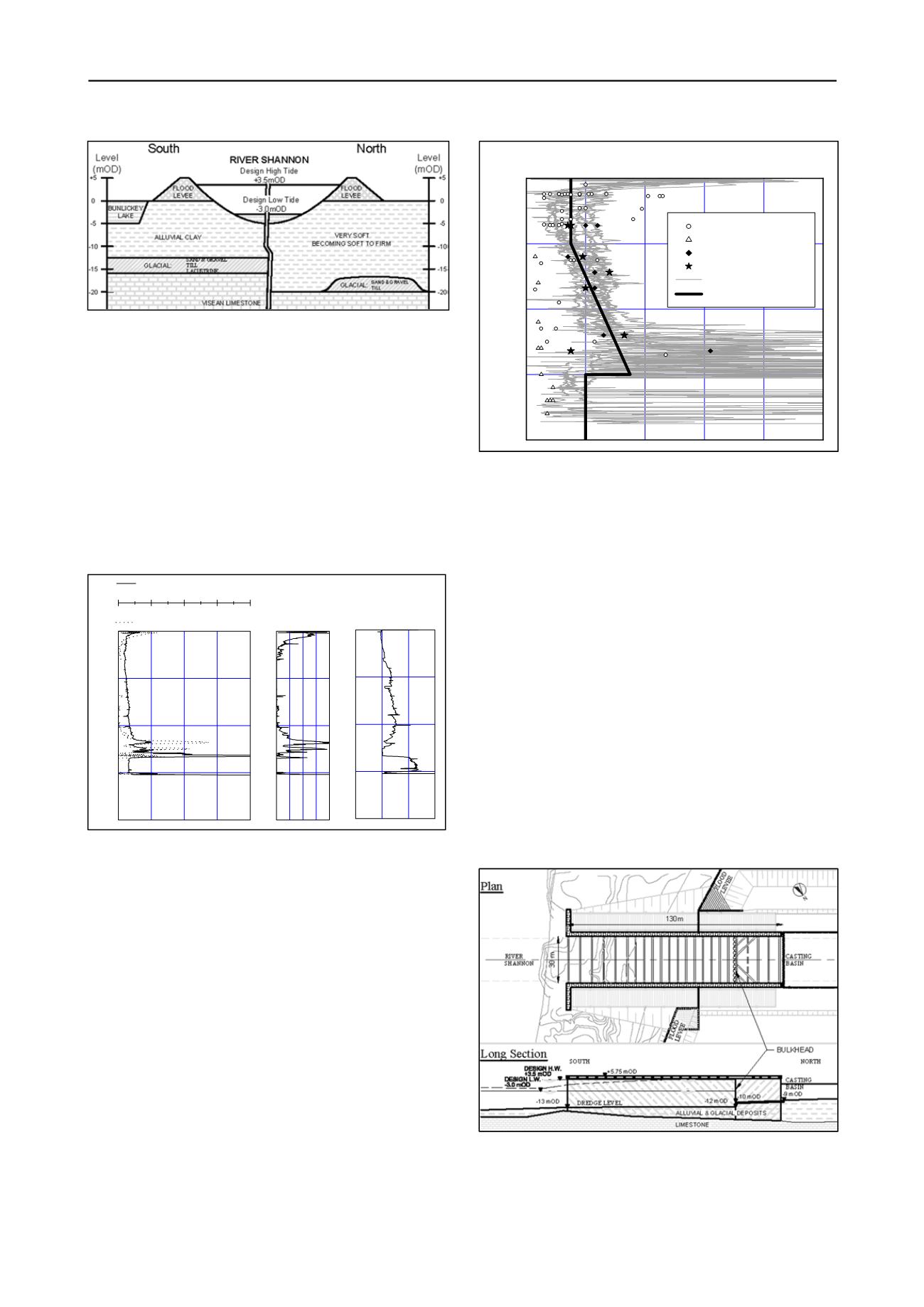

Figure 2. Schematic ground section along line of tunnel

The properties of the alluvial clay dominated the design of

the tunnel. They were investigated primarily using static cone

penetration tests (CPTs). Figure 3 shows a typical CPT profile.

There is a thin crust, below which the strength decreases, then

gradually increases again with depth. Between 11.5 and 13.5 m

the end resistance increases significantly, and this layer is

believed to be a paleo-surface which at some time has dried out.

Below it, the cone resistance decreases substantially. Over

much of the depth of the clay, the sleeve friction is zero. This is

believed to result from the very sensitive nature of the clay,

which liquefies as it is penetrated by the cone, so the friction

sleeve measures no strength. The measured pore pressures were

correspondingly very high.

Figure 3. Typical static cone test profile

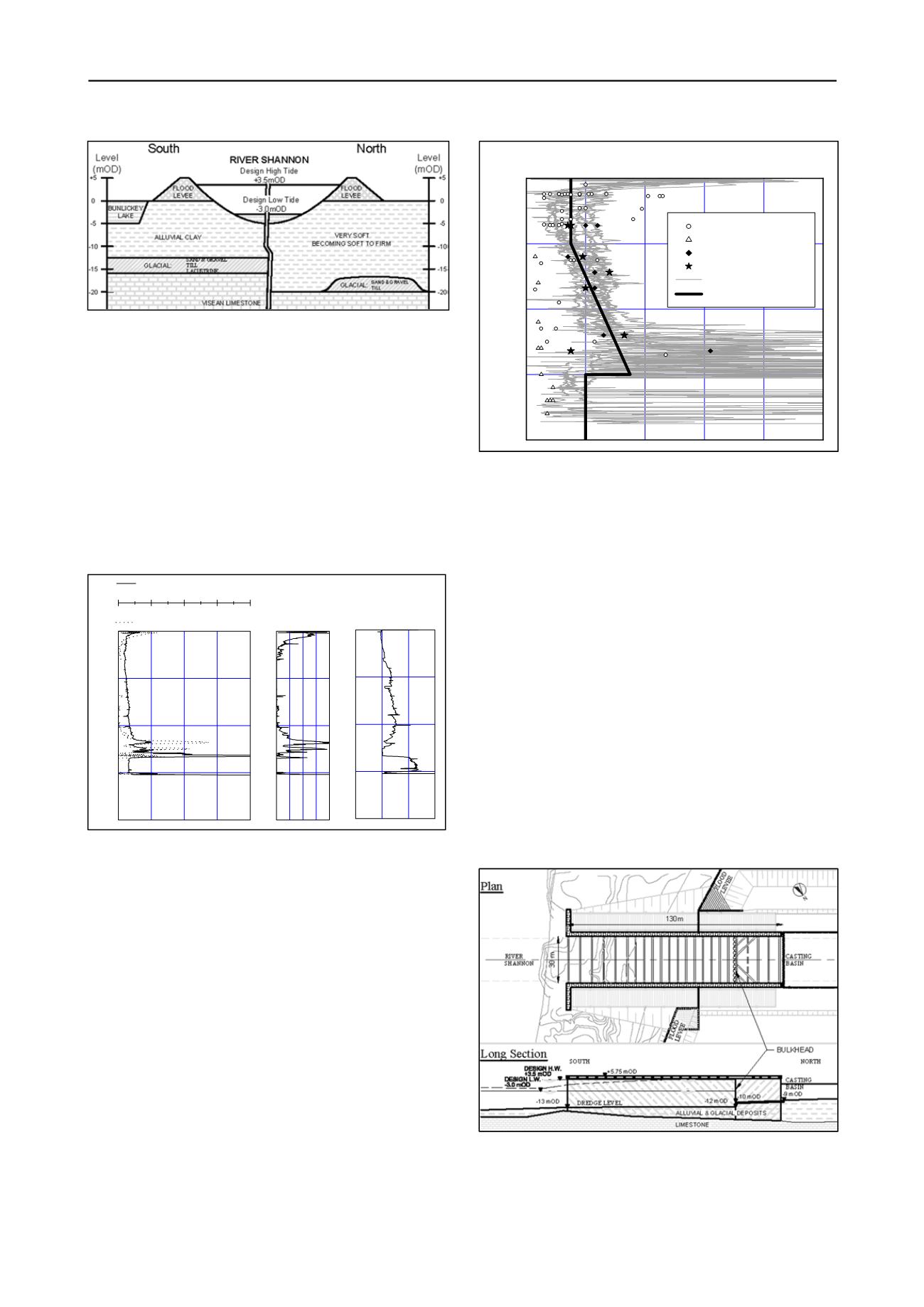

Figure 4 shows a composite plot of cone resistance, plotted

as interpreted undrained shear strength, together with the design

profile adopted and results from undrained triaxial tests on

U100 samples and from vane tests carried out in boreholes.

Both the triaxial tests and the vane tests gave much lower values

than the cone tests. It was believed that the very sensitive

nature of the clay led both to sample disturbance and to

disturbance below the base of the borehole. In order to verify

the design profile, high-quality “Mostap” push samples were

taken using the cone equipment, and subjected to

unconsolidated undrained and direct simple shear tests. These

gave values straddling the design profile from the cone tests,

and hence gave additional confidence in its use. Buggy and

Peters (2007) derived a very similar shear strength profile for

the approach roads to the tunnel.

Figure 4. Undrained shear strength results for alluvial clay

It may be noted that the design shear strength profile

corresponds to a value of the ratio s

u

/

σ

v

’ of between 0.30 and

0.35. This is comparatively high for a normally consolidated

clay. Two cone tests were carried out from the top of the flood

levees, where the value of

σ

v

’ would be expected to be 80 to

100 kPa greater, but to have been applied for a comparatively

short period. These gave higher shear strengths, but a lower

value of s

u

/

σ

v

’ of 0.24, consistent with what would be expected

for normally consolidated clay. It is therefore believed that the

high strength ratio of the clay results from some form of aging.

3 DESCRIPTION OF ENABLING WORKS

As briefly described above, the tunnel units were constructed in

an in-line casting basin on the north side of the river. They

were floated out through an open-ended retained excavation

130 m by 30 m (Figure 5). A bulkhead 30 m from the casting

basin end retained the river, and was removed when the casting

basin was flooded. On immersion, the tunnel units were placed

in a trench dredged across the river. The first unit was

connected to a cut and cover section at the southern side of the

river. This was constructed in a second retained excavation,

also 130 m by 30 m, which was essentially a closed-ended box.

Figure 5. Northern float-out section

Retention for both structures was provided by 1420 mm

tubes and pairs of sheet piles. On the north side of the river, the

glacial deposits overlying the limestone were not continuous.

Dowels were therefore drilled into the limestone to provide toe

20

15

10

5

0

0

50

100 150 200

Sleeve Friction f

s

(kPa)

Depth (m)

0

2

4

6

8

Total Cone Resistance, q

t

(MPa)

0 2 4 6 8

Friction Ratio (%)

-1 0 1 2

Pore Pressure Ratio

20

15

10

5

0

0

20

40

60

80

100

UUs: U100 samples

In-situ vanes

UUs: push samples

DSSs: push samples

Cone tests, N

kt

= 17

Design profile

Undrained Shear Strength (kPa)

Depth (m)