808

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

4

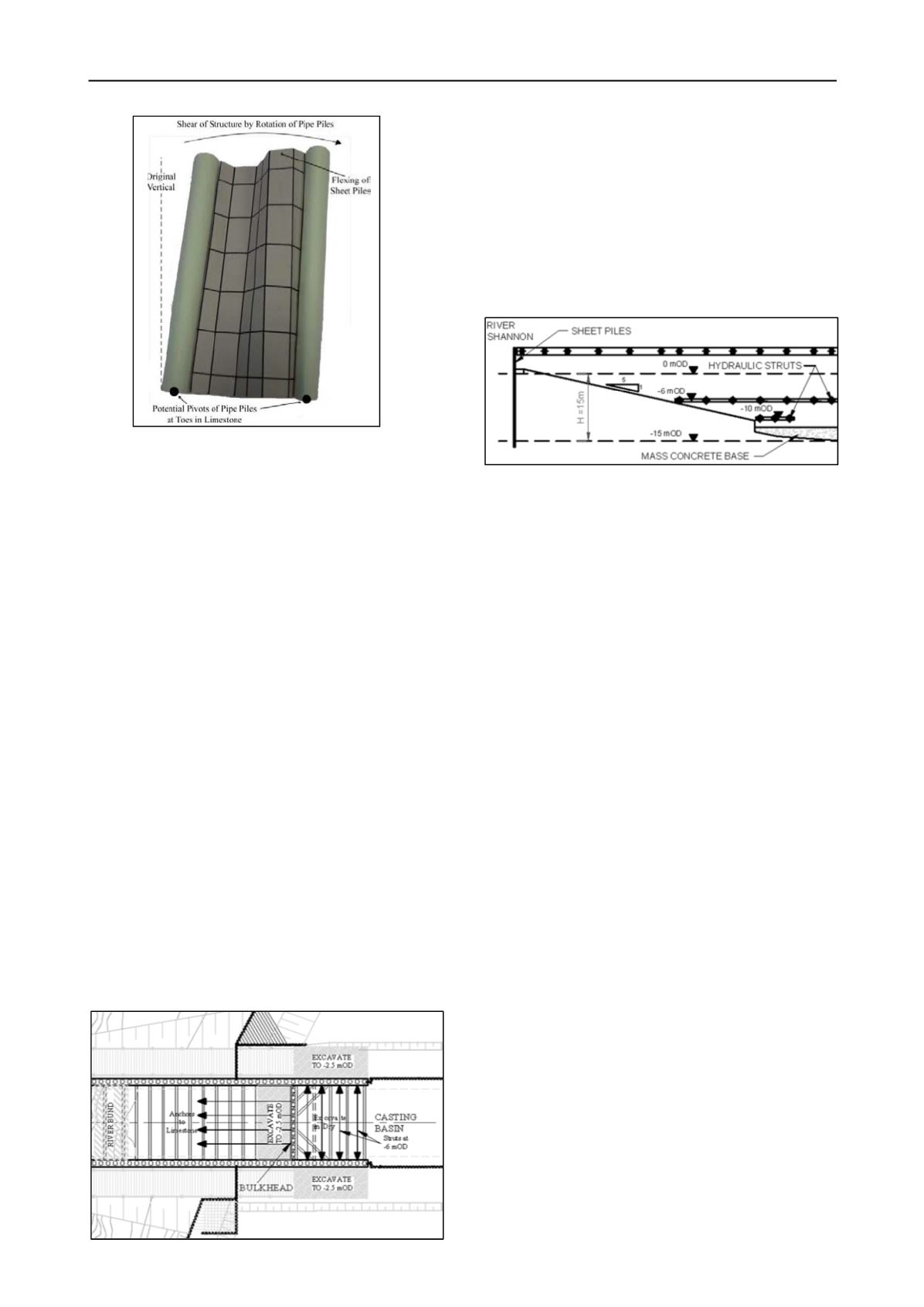

Figure 9 Model to illustrate potential “shear” mechanism

5 CHANGES TO CONSTRUCTION OF FLOAT-OUT

SECTION

Design calculations had indicated that excavating north of the

bulkhead in the dry would lead to excessive moments in the

piles. It was therefore intended to install temporary sheet piles

between this area and the casting basin, and to excavate and cast

the base slab under water. During construction of the southern

cut and cover section, considerable difficulties were

experienced maintaining a suitable surface for underwater

casting of the base slab, due to large volumes of suspended silts

slowly settling there. In addition, excavation underwater,

although practicable, was much slower than excavating in the

dry. It was therefore decided to develop a strategy for

excavating north of the bulkhead in the dry.

By this time considerable experience had been gained in

construction of the casting basin. Although not as deep as the

two structural sections, it was a substantial excavation in its

own right. It was retained by sheet piles with anchors at high

level, inclined at 45°. Despite the free length of up to 30 m

through soft clay, installation into the limestone to achieve a

working anchor load of 1 MN had become reasonably routine.

The sheet piles were also retained by struts below the casting

basin floor. Before the permanent struts were installed, the

walls were supported by temporary hydraulic struts.

A combination of these techniques was adopted for the

float-out section. The key to their success was the reduction of

the external soil and water forces on the walls. This was

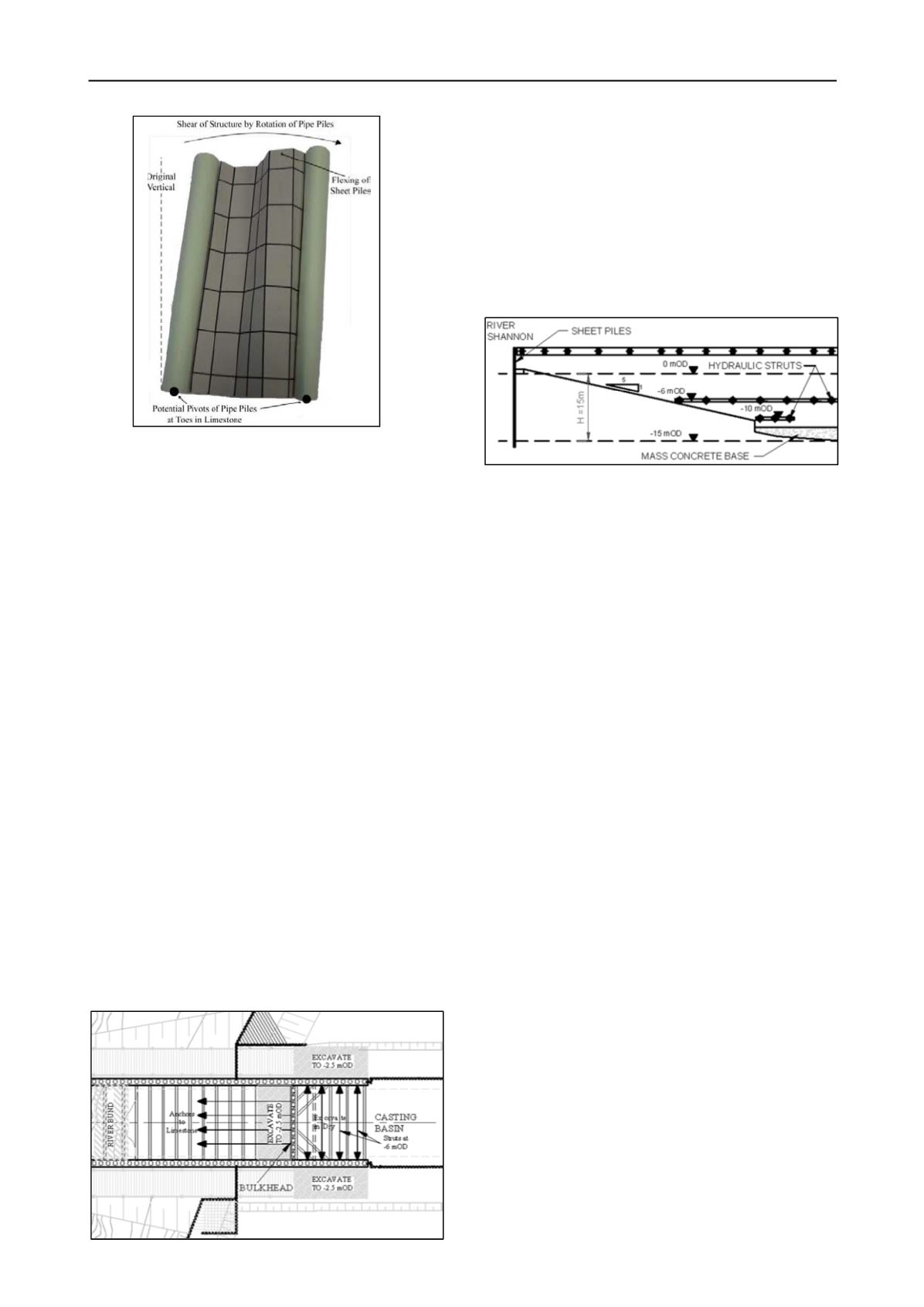

achieved (Figure 10) first by constructing a bund at the far

southern end of the section to prevent the river from acting

against the bulkhead. Then 2.5 m deep excavations were made

outside each wall. Temporary struts were installed between the

side walls at -6 mOD, and anchors installed at the same level in

the bulkhead.

This operation demonstrated again how much easier

excavation was in the dry rather than underwater.This factor,

together with a change in the design of the permanent tunnel

works, led to a requirement to excavate in the dry on the river

side of the bulkhead also. A construction sequence was devised

(Figure 11), which again involved the use of temporary struts

(this time at two levels), the exclusion of the river by means of

bunds outside the walls, and the reduction of ground level

outside the walls. Other features were a sheet pile wall across

the open end of the excavation, a 1:5 slope down from the sheet

pile wall, and a 3 m thick mass concrete slab at -12 mOd as

permanent works to support the northernmost tunnel unit.

Figure 11. Section through new construction measures

These proposals were set out on a colour-coded plan, to

facilitate their checking by the design consultants. The

checking led to some minor changes in detail, and to the

identification of one potential major problem. This involved the

stability of the end slope, which although only 1:5, would be

15 m high after excavation for the mass concrete slab. A simple

calculation using Taylor’s curves demonstrated that an average

shear strength of 33 kPa was required to achieve a safety factor

of 1.3 against undrained failure, considerably greater than the

design values (Figure 4). The slope was therefore flattened still

further, to about 1:8. Its toe was raised to -6 mOD, and further

excavation at the toe supported by an anchored sheet pile wall.

These works were successfully implemented, and float-out

of the first tunnel unit took place on programme on 7th

September 2008.

6 CONCLUSIONS

Successful construction of the Limerick Tunnel enabling works

was achieved despite the complexity of the structures and the

challenging nature of the ground conditions. Technically, one

of the most important factors was that the forces on the

structures were dominated by water and ground levels, and

therefore that significant advantages could be achieved if these

levels could be controlled and hence varied.

Most of the analyses were carried out using

industry-standard software. Simple calculations for force and

moment equilibrium slope stability proved also to be of great

value. Perhaps more important than the calculations was the

identification of mechanisms that needed to be analysed. Tools

to aid understanding of these included isometric diagrams

(Figure 6), graphs (Figure 8), a physical model (Figure 9) and

colour-coded plans. Such simple but effective tools enabled

designers and constructors to achieve a common understanding

of the project and hence its successful completion.

7 REFERENCE

Buggy, F. And Peters, M. 2007. Site investigation and characterisation

of soft alluvium for Limerick Southern Ring Road – Phase II,

Ireland.

Proc. IEI Conference on Soft Ground, Port Laoise,

paper 1.6

.

Figure 10. Measures adopted to enable construction in the dry