819

Technical Committee 103 /

Comité technique 103

Vreugdenhil at al. (1994), which indicated even a larger value

of approximately

100

ڄ

r

.

The stiffness of the sand layer is apparently independent of

the layer thickness, which becomes evident from the congruent

transition curves when approaching and penetrating the sand

layer. An increase or decrease, respectively, of the stiffness can

be seen, however, for varying relative densities as shown in

Figure 4. A similar result is obtained when varying the clay

strength and the vertical consolidation stress; not shown.

Figure 5 presents the equivalent tip resistance in drained

sand normalised with the equivalent tip resistance of the

reference simulation using the reference parameters listed in

Section 3, viz.

The equivalent strength of the drained sand layer in the

reference model amounts (

T

eq

sand

/T

clay

)

re

f

=3.44

.

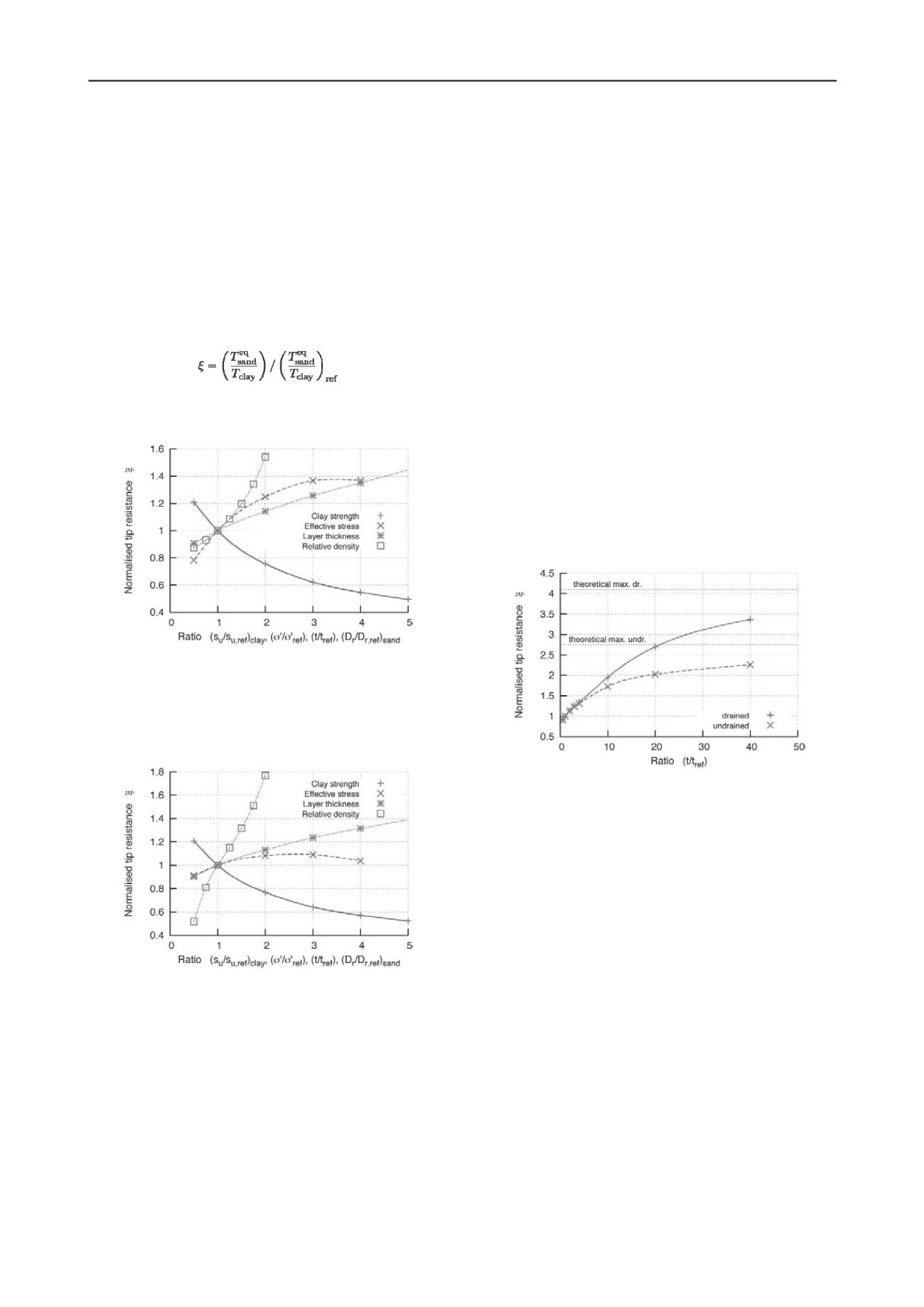

Figure 5 Normalised resistance of the drained sand layer depending on

the shear strength of the clay, effective consolidation stress, thickness of

the sand layer and relative density of the sand.

Figure 6 presents the normalised equivalent tip resistance in

undrained sand normalized with the corresponding reference

simulation using the same reference parameters.

Figure 6 Normalised resistance of the undrained sand layer depending

on the shear strength of the clay, effective consolidation stress,

thickness of the sand layer and relative density of the sand.

The curves of the normalized resistances of both drained and

undrained sand are very similar. Almost identical curves are

obtained for varying shear strengths of the clay layer.

The effective consolidation stress has only a small influence

on the resistance in undrained sand, which is plausible since the

relative density governs the undrained strength of sand.

More pronounced is the effect of the relative density being

larger under undrained conditions. The double-bended curve is

somewhat unexpected. However, the resistances at low densities

(

25%

and

37.5%

) are in practice less relevant. Noticeably,

however, is, that the actual values are smaller than expected

based on the diagrams proposed Baldi et al. (1986). But since

the tip resistance in pure sand as measured by Baldi et al. (1986)

can be well reproduced by the FE model using the hypoplastic

formulation (Cudamni and Sturm, 2006), it is believed that the

lower normalised relative resistances at high relative densities

are affected by the layer thickness. The sand is squeezed

horizontally but also vertically into the softer clay which results

in a lower resistance. The squeezing can be well seen in the

deformed mesh when high densities and low undrained shear

strengths for the clay are used. In some cases it lead to distorted

elements introducing numerical difficulties. These simulations

have not been included in the presented diagrams. The vertical

squeezing explains also the higher resistances under undrained

conditions compared to drained conditions. The excess pore

pressure is less than during penetration in pure undrained sand

with similar properties, resulting in higher effective stresses

under the tip and hence higher penetration resistance.

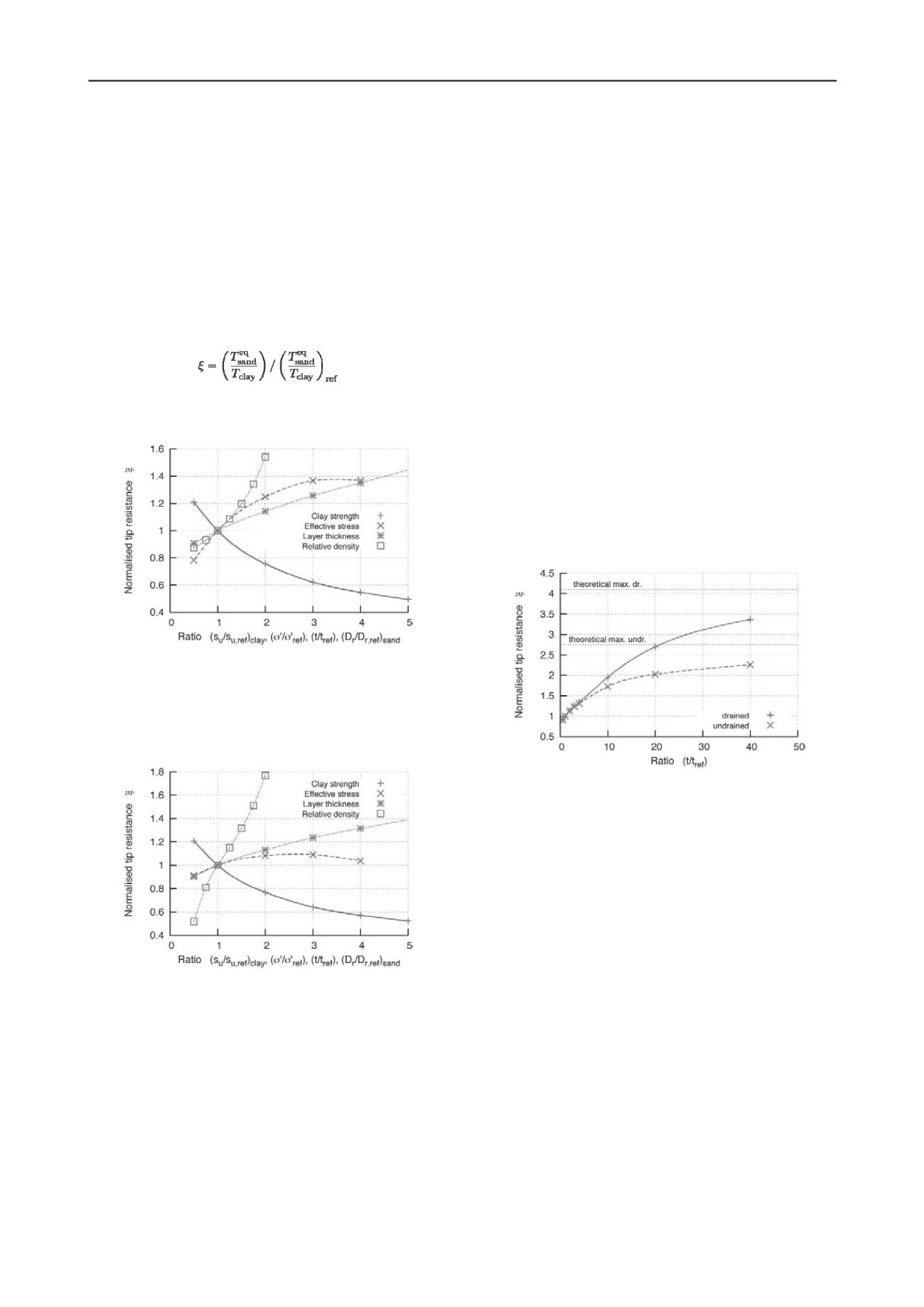

In case of very thin to thin layers, the effect of the thickness

on the penetration resistance is almost independent of the

drainage conditions of the sand. However, when plotting these

curves over a larger range, as shown in Figure 7, it becomes

apparent that the effect is larger under drained conditions. In

addition the theoretical residual maximum normalised resistance

for drained and undrained conditions are plotted in Figure 7.

The curves approaching the theoretical values only

asymptotically, but it is reasonable to assume a value of

approximately

80

ڄ

r

to

100

ڄ

r

as an upper limit at which a further

increase of the thickness has a negligible effect on the

equivalent resistance.

Figure 7 Normalised resistance of the drained and undrained sand layer

depending in the layer thickness.

5 APPLICATION RANGE AND LIMITATIONS

5.1

Application

In order to use the results shown in Figure 5 to Figure 7 for

other design cases than the ones simulated, the different

normalised resistance factors just need to be multiplied. For

example, the normalised resistance of a drained sand layer with

s

u,

clay

=12.5

kPa,

’

v

=200

kPa,

t=2

ڄ

r

and

Dr=100%

is

=1.21·1.25·1.14·1.54=2.66

or

T

eq

sand

=3.44·2.66=9.15·

T

clay

,

respectively, where

T

clay

=N

c

·

·r

2

·s

u,

clay

with

s

u,

clay

=12.5

kPa.

This value agrees well with the result of a corresponding FE

calculation.

The plausibility of this approach becomes apparent from the

following simple example: considering two drained sand layers

with equal density and thickness embedded in normal

consolidated clay but at different depths. The vertical effective

stress and the strength of the normal consolidated clay increase

linearly with depth. The equivalent tip resistance should be then

almost equal in both sand layers, meaning that both effects

should cancel out, given that the sand resistance is stress

independent. This, however, is not the case in the hypoplastic

formulations. Thus, the resistances are only approximately

similar within a range of

±50%

.

In practice, the diagrams are used to estimate the scaling

effects and to provide input for sensitivity studies. Starting point

in most cases will be a CPT profile indicating the presence of a