822

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

ground engineering situations where the critical period for

stability is immediately, or very shortly, after construction, e.g.

any form of ‘foundation loading’ of free-draining or slow-

draining soils. In such situations it is common practice to

incorporate geosynthetic basal reinforcement to provide an

additional stabilizing force. The stability of the system will

improve in time and so the stabilizing force, which needs to be

provided by the geosynthectic, will diminish. After a certain

time (typically between a few months and a few years) the

whole system will be stable with little or no assistance from the

geosynthetic – in many cases the geosynthetic becomes totally

redundant. In such a situation, the use of a non-conventional

geosynthetic, which has a limited, but predictable working life,

is sound engineering practice. This is the concept of limited life

geotextiles (LLGs). In this paper, the interactions between

Kenaf geogrid which is a kind of Limited Life Geosynthetics

(LLGs) have been measured and numerically simulated.

3 INTERACTION BETWEEN BACKFILL SOIL AND

REINFORCEMENT BY PULLOUT AND DIRECT SHEAR

TEST

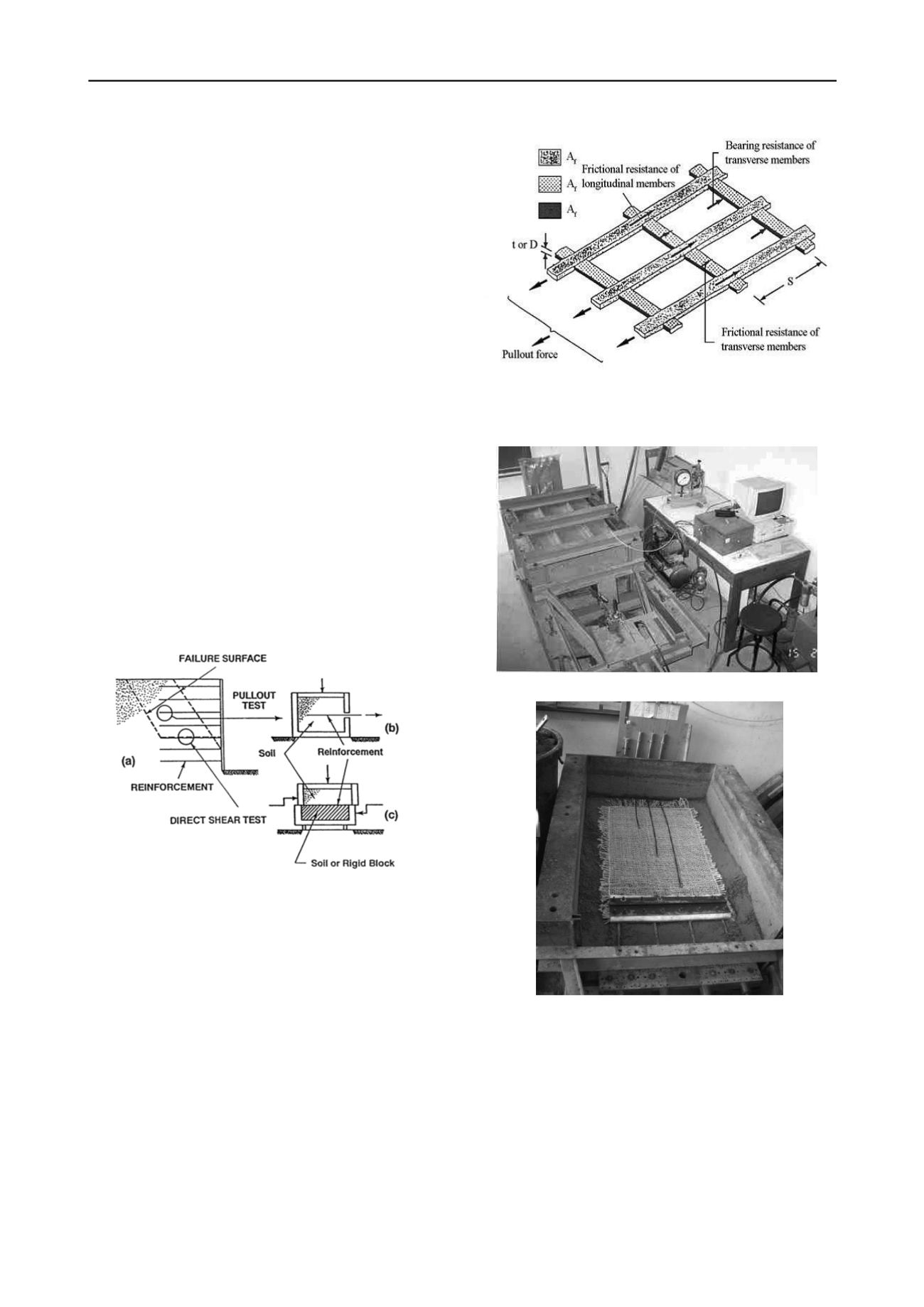

In reinforced earth structures, the interaction between grid

reinforcement (e.g. inextensible and extensible grid

reinforcements) and soil can be simplified into two types: a)

direct shear resistance and b) pullout resistance. Direct shear

resistance can be represented as soil sliding over the reinforcing

material, but for pullout resistance, it is the pulling of

reinforcements out from the fill material. The dashed line shown

in Fig. 1 represents the potential failure of a typical reinforced

structure. Such direct shear and pullout resistance can be

investigated by conducting direct shear and pullout tests under

various soil types and a range of normal stresses, respectively.

Figure 1. Interactions between soil and reinforcement

3.1. Pullout mechanism

Pullout resistance of grid reinforcements embedded in backfill

soils basically consists of two resistance contributions; the

former is frictional resistance and the latter is passive or bearing

resistance. In case of geogrid reinforcements, the shape of

longitudinal and transverse ribs are flat, therefore, the frictional

resistance can be mobilized along not only the surface area of

the longitudinal ribs, but also the surface area of the transverse

ones as shown in Fig. 2.

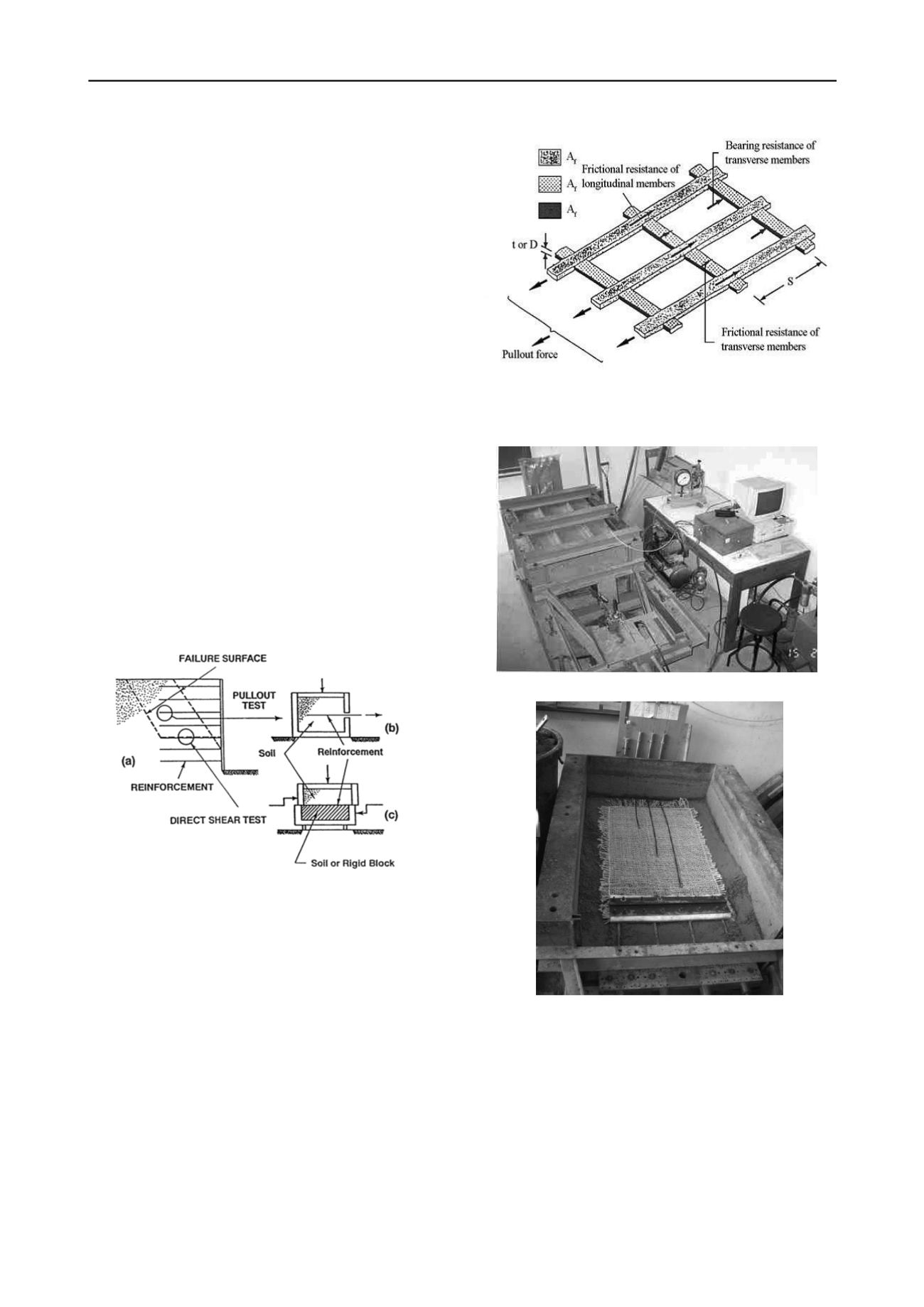

Pullout test was conducted to determine displacement and

structure of LLGs reinforcement layer needed to achieve active

limit state in order to exploit reinforcement’s load capacity

properly (Artidteang et al., 2012). The pullout machine which

performed testing is show in Fig. 3. Pullout force was measured

by a load cell connected to the data logger. High strength wires

were connected to the longitudinal rib and the other ends were

connected to the LVDTs to measure the displacement (Fig. 4)

Figure 2. Components of pullout resistance for geogrid reinforcement

(Jewell et al., 1984)

Figure 3. Pullout machine (Artidteang et al., 2012)

Figure 4. Position of LVDTs attached on the woven kenaf LLGs

(Artidteang et al., 2012)

3.2. Direct shear mechanism

Direct shear resistance between soil and grid reinforcement

generally consists of three components. The first component is

the shearing resistance between the soil and the surface area of

grid reinforcement, the second component is the soil-to-soil

shearing resistance at the apertures of grid reinforcement, and

the last component is the resistances from soil bearing on the

bearing surfaces of grid reinforcement (Jewell et al., 1984) see

Fig 5.

The large-scale direct shear test conducted for evaluating

the friction between backfill soils only and between kenaf LLGs