824

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

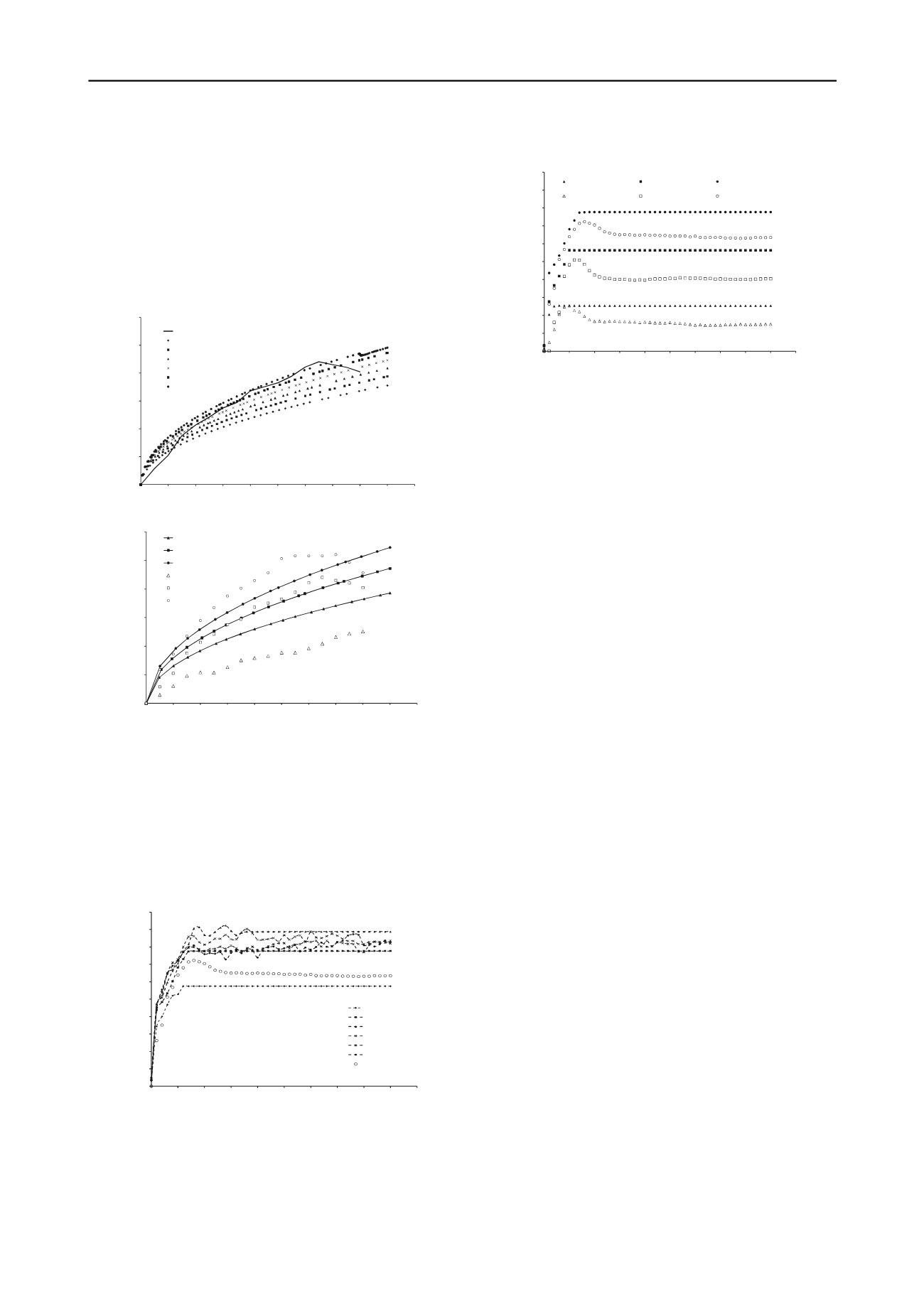

coincide with the laboratory results as shown in Fig 10. The

comparison between laboratory test and predicted results are

made in Fig. 11 for pullout test. The results of simulation

captured well with laboratory test results.

After the maximum pullout resistance, the predicted results

show constant residual strength as compared to the measured

results. The reason might be consideration of PLAXIS to

geogrid element as rough sheet which did not show any

damages in geogrid as it occurred in laboratory. Average back-

calculated interaction factor for Kenaf and compacted sand is

0.9 in pullout mode.

Figure 9. Parametric study of R

inter

for normal stress of 40 kPa.

Figure 10. Pullout test between FEM and laboratory test results

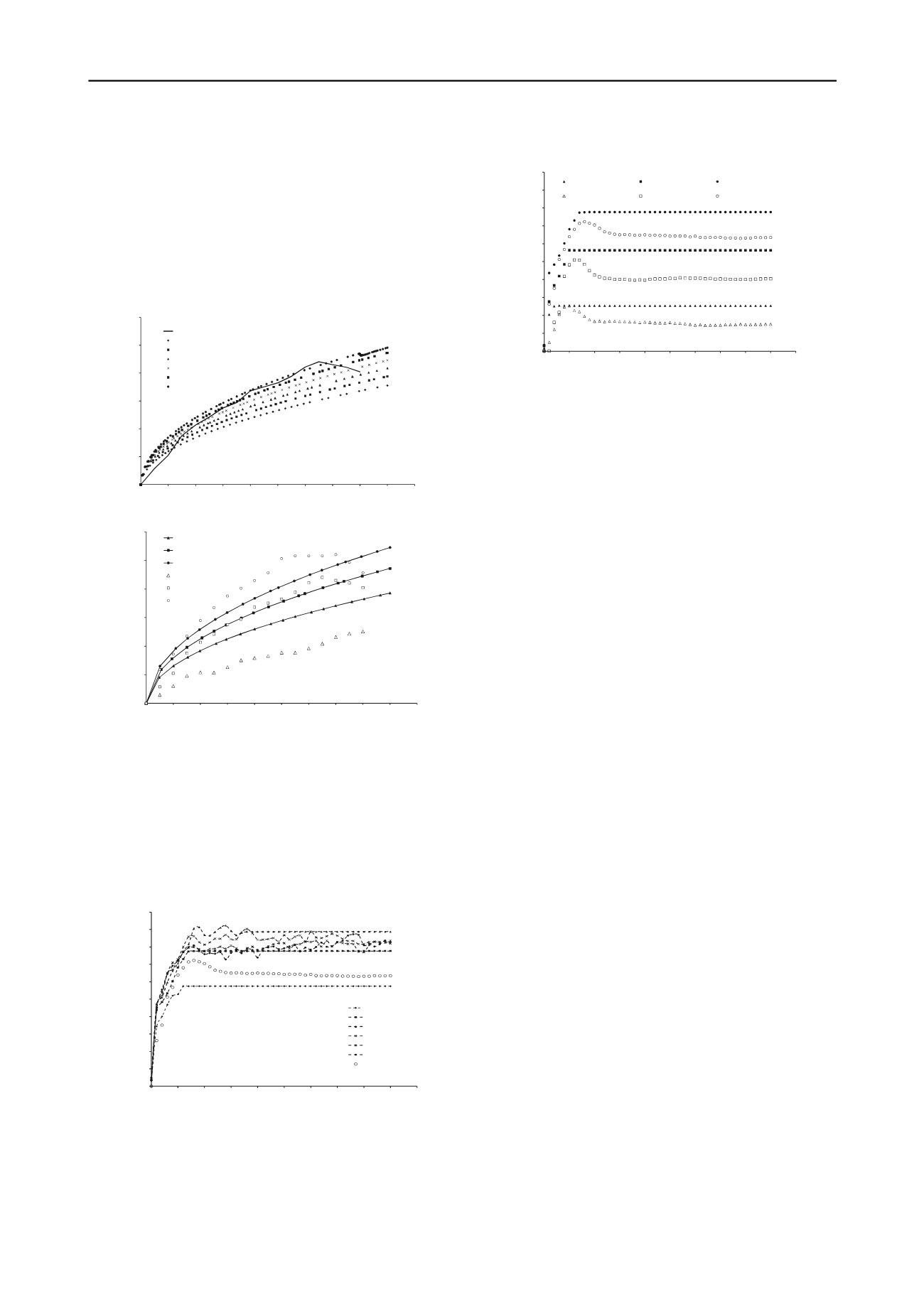

5.2. Direct shear mode

For direct shear test simulation, the interaction coefficient (R)

also varied in order to parametric study for this variable as

shown in Fig. 12. The sensitivity analysis show that the

interaction coefficient (R) of 0.6 is good fit with laboratory

results. The comparison between laboratory test and predicted

results are made in Fig. 13 for direct shear test. The results of

simulation captured well with laboratory test results.

Figure 11. Parametric study of R

inter

for normal stress of 120 kPa.

Figure 12. Direct shear test between FEM and laboratory test results

6. CONCLUSIONS

The purposes of this study are to assess the interactions between

the Kenaf geogrid and compacted sand as well as perform the

numerical simulations by finite element analyses. Sensitivity

analyses were also performed for the pullout and direct shear

test by varying the interaction coefficient. The back-calculated

from numerical simulations average values of interaction

coefficients were found to be similar as to the measured results.

The interaction coefficient and axial stiffness of the geogrid

were found to be important parameters affecting the efficiency

of geogrid. The interaction coefficient R

inter

is 0.9 for pullout

mechanism and 0.6 for direct shear mechanism. These

parameters are useful for analysis and design of reinforced soil

structure using kenaf geogrid and compacted sand. Limited Life

Geotextiles (LLGs) from Kenaf geogrid can be used as natural

fibers for sustainable geosynthetics.

7. ACKNOWLEDGEMENTS

This study is part of research granted by Thailand Research

Fund (TRF) in cooperated with Commission of Higher

Education and Chiang Mai University under New Researcher

Project FY 2011. Laboratory test data were obtained from the

Asian Center for Soil Improvement and Geosynthetics (ACSIG)

of the Asian Institute of Technology, Bangkok, Thailand.

8. REFERENCES

Artidteang S., Bergado D. T., Tanchaisawat T. and Saowapakpiboon S.

2012. Investigation of tensile and soil-geotextile interface strength

of kenaf woven limited life geotextiles (LLGs).

Lowland

Technology International,

14(2), 1-8.

Belton J. 2008. Using geosynthetics to meet the challenge of improving

material resource efficiency.

Proceedings of EuroGeo4

, Scotland,

Paper #128, 7-10

Brinkgreve R. B. and Broere W. 2003.

PLAXIS 2D Version 8 Manual

.

Balkema, A. A., Rotterdam, Brookfield, Netherland.

Jewell R. A., Milligan G. W. E., Sarsby R. W. and Dubois D. 1984.

Interaction between soil and geogrids,

Proceedings of

the

Symposium on Polymer Grid Reinforcement in Civil Eng

., Thomas

Telford Limited, London, U.K., 19-29.

Mwasha A. 2005. Limited life geotextiles for reinforcing an

embankment on soft ground.

PhD Thesis

, University of

Wolverhampton, U.K.

Mwasha A. and Sarsby R. 2003. Use of vegetable fibre geotextiles

(VFGs) for ground improvement.

Proceedings Cobra

, University

Wolverhampton, U.K.

Robinson P. N. J. and Quirk C. M. 2008. The UK aggregate levy and its

implications to geosynthetics.

Proceedings of EuroGeo4

, Scotland.

Sarsby R., Mwasha A., Searle D. and Karri R. S. 2008. Sisal fibre

geotextiles for soil strengthening.

Proceedings of the 8th

International Geosynthetics Conference

, Millpress Science

Publisher. ISBN:90 5966 044 7.

0.00

10.00

20.00

30.00

40.00

50.00

60.00

70.00

80.00

90.00

100.00

0.000 0.005 0.010 0.015 0.020 0.025 0.030 0.035 0.040 0.045 0.050

Shear Stress (kPa)

Horizontal Displacement (m)

σ=

40kPa (FEM)

σ= 80

kPa (FEM)

σ= 120

kPa (FEM)

σ=40

kPa (Lab Results)

σ= 80

kPa (Lab Results)

σ=

120 kPa (Lab Results)

0.00

10.00

20.00

30.00

40.00

50.00

60.00

70.00

80.00

90.00

100.00

0.000 0.005 0.010 0.015 0.020 0.025 0.030 0.035 0.040 0.045 0.050

ShearStress(kPa)

Horizontal Displacement (m)

R=0.5 FEM

R=0.6 FEM

R=0.7 FEM

R=0.8 FEM

R=0.9 FEM

R=1.0 FEM

Lab Results

0.00

5.00

10.00

15.00

20.00

25.00

30.00

0.000

0.010

0.020

0.030

0.040

0.050

0.060

0.070

0.080

0.090

0.100

Pullout Force (kN/m)

Horizontal Displacement (m)

= 40

LAB

R0.5FEM

R0.6FEM

R0.7FEM

R0.8FEM

R0.9FEM

R1.0FEM

0.00

5.00

10.00

15.00

20.00

25.00

30.00

0.000

0.010

0.020

0.030

0.040

0.050

0.060

0.070

0.080

0.090

0.100

Pullout Force (kN/m)

Horizontal Displacement (m)

σ=

20kPa(FEM)

σ=

40kPa(FEM)

σ= 60

kPa(FEM)

σ= 20

kPa(LAB)

σ= 40

kPa(LAB)

σ= 60

kPa(LAB)

R = 0.9