756

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

p’ is constant in undrained loading. The behavior changes when

the initial yield locus is reached and the clay begins to yield.

The direction of the undrained stress path is then determined by

the tendency of the clay fabric to compress or dilate. The

direction and shape of the stress path (and at the same note, the

amount of excess pore pressure) depends on several factors such

as the shape and size of the initial yield surface, initial stress

state and the rate of loading.

According to Länsivaara (1999) a high strain rate results in

less excess pore pressure than a comparably lower strain rate

due to effects related to undrained creep. The result of this

behavior is that high strain rates result in higher undrained shear

strength than comparably lower rates.

2.1

Failure pore pressure in LEM

In conventional undrained c’-φ’ calculations there is an inherent

overestimation of shear strength when for any factor of safety F

> 1. This is caused by the fact that for a given loading the

mobilized excess pore pressure is used in calculating the

equilibriums and shear strength. This approach disregards the

further increase of excess pore pressure between the mobilized

stress state and failure (which is not a problem in drained

calculations).

Shear stress is traditionally defined in LEM as:

e

f

F

(1)

where τ

e

is the equilibrium shear stress, τ

f

the corresponding

shear strength and F the factor of safety. This definition implies

a very specific stress path that is highly unrealistic in undrained

loading, for example under an embankment. (Tavenas et al

1980).

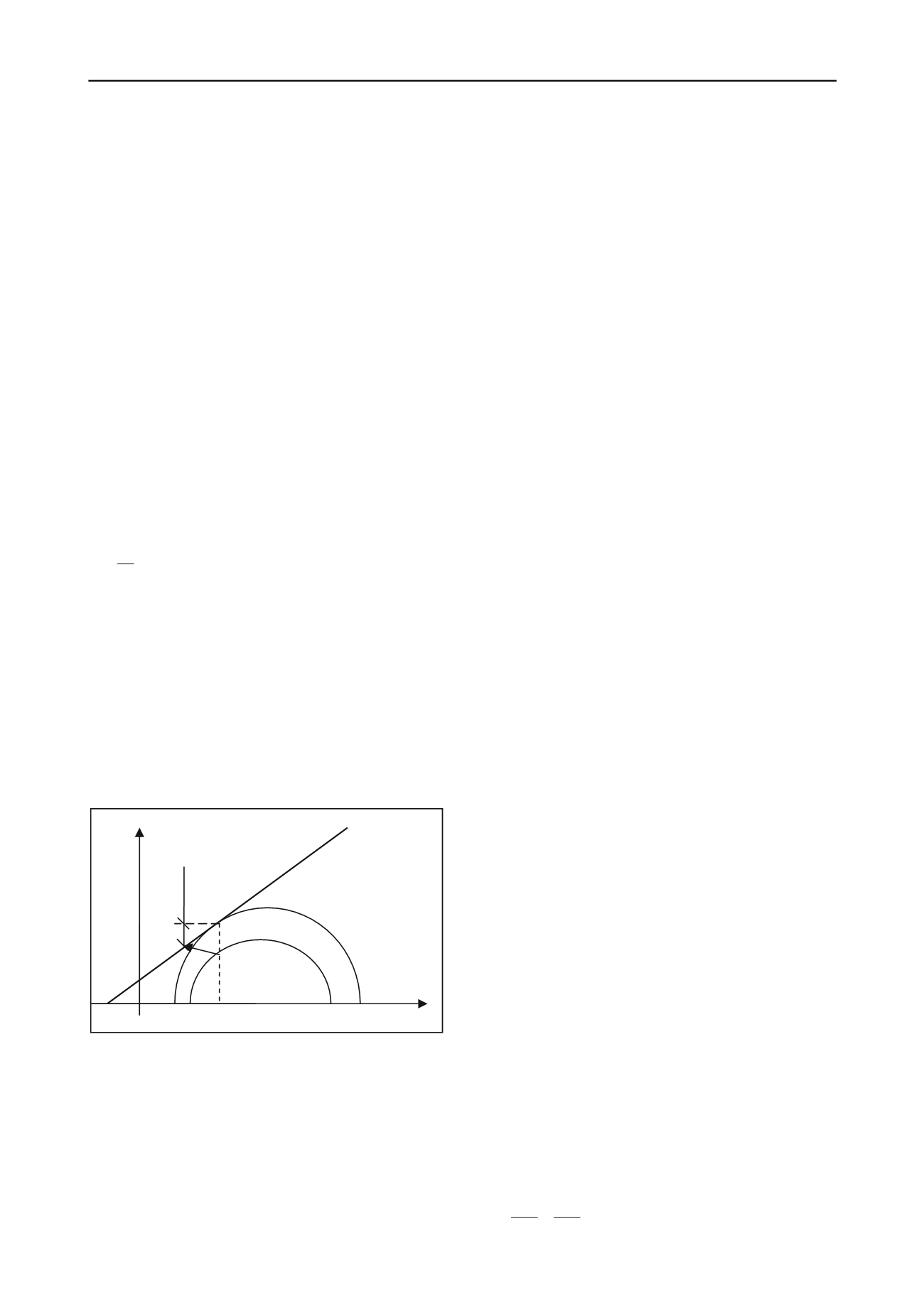

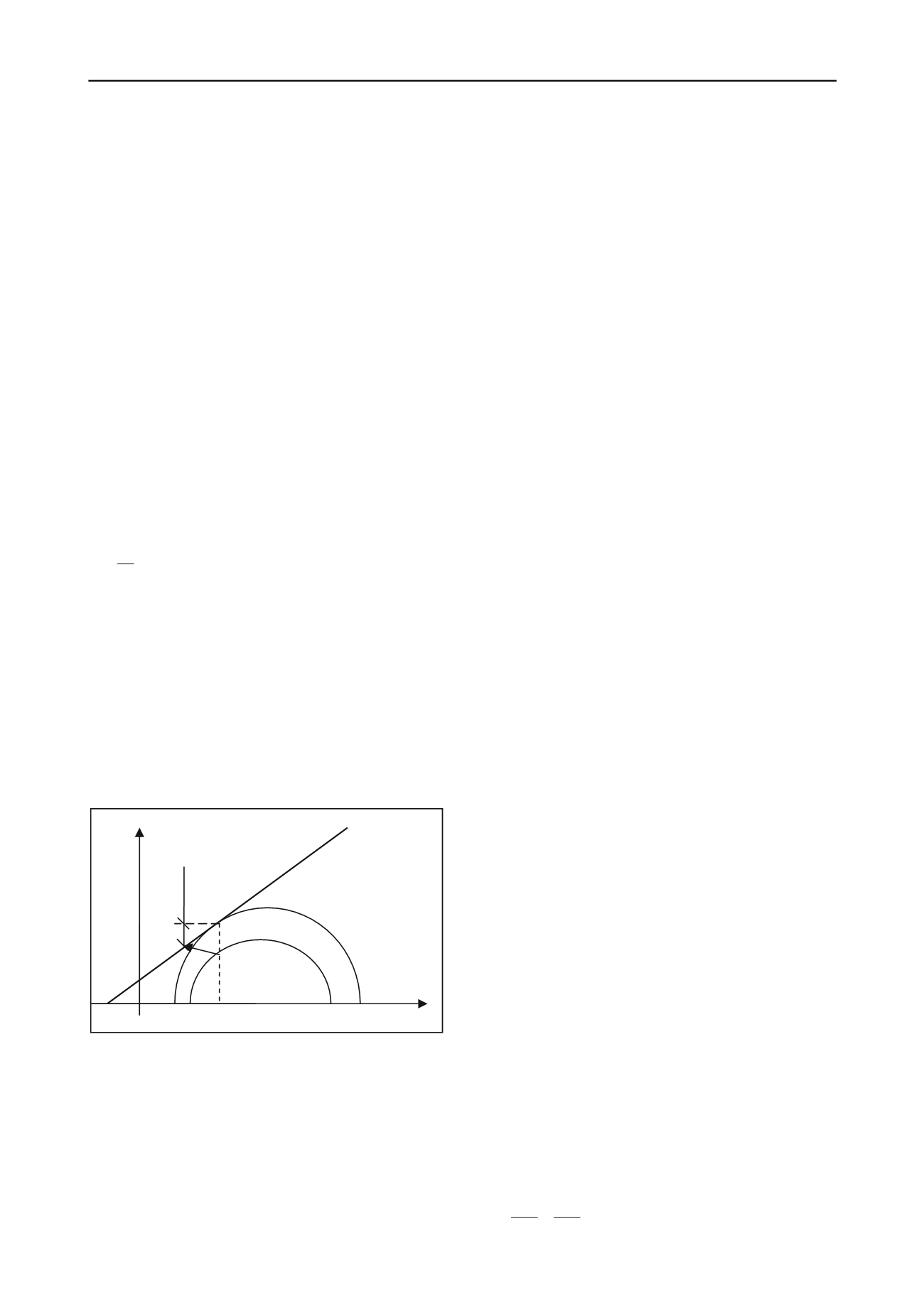

The corresponding definition of shear stress effectively

compares the mobilized shear stress τ

e

to an unrealistically

large strength τ

f

that can never be attained because of further

pore pressure buildup between the mobilized state and failure

(Figure 2). This pore pressure behavior is common for soft

normally consolidated or slightly overconsolidated clays that

generally exhibit compressive behavior.

Figure 1. Overprediction of shear strength in typical undrained effective

stress calculations. (Länsivaara et al 2011)

Consequently the definition of the factor of safety in undrained

c’-φ’ calculations is actually different from the factor of safety

in φ = 0 calculations. In φ = 0 calculations the mobilized shear

stress τ

e

is always compared to a value of s

u

that represents the

shear strength τ

fe

that can actually be mobilized for a given set

of physical conditions (consolidation, rate and direction of

shearing etc). The two otherwise conflicting definitions coincide

at F = 1. As a conventional undrained c’-φ calculation for soft

clays will overestimate shear strength when F > 1, one cannot

even in theory expect the same result from a corresponding φ =

0 calculation (Leroueil et al 1990).

In light of this issue it is not enough just to accurately model

the mobilized excess pore pressure, but the implicit

overestimation of the factor of safety should also be taken into

account if possible. At the least, the designer needs to be aware

of these theoretical differences between the two methods and

interpret the results accordingly.

A proposed workaround for the overestimation of shear

strength is to universally use failure state pore pressure in the

calculation even for F > 1, regardless of the actual mobilized

pore pressure. This can be achieved in LEM if the effective

stress path from the initial state to failure (and the

corresponding excess pore pressure) can be approximated. In

(σ’

n

, τ) stress space this assumption places the effective normal

stress to its value at failure, thus giving the ability to compare

the shear stress with the shear strength at failure.

Since τ and F are co-dependent in LEM the mobilized shear

stress τ in the “failure pore pressure formulation” will be

slightly different from the corresponding “traditional” pore

pressure formulation. Whether the difference will be positive or

negative depends on several factors. According to studies with

the method “MUESA” (section 2.3) the induced error on the

factor of safety is small when compared to the overestimation of

shear strength caused by the traditional use of mobilized pore

pressure.

What the use of failure pore pressure does is effectively to

substitute an “incorrect” effective normal stress to obtain a more

realistic calculated shear strength. In LEM this can be

considered an acceptable tradeoff as the main purpose of LEM

is to obtain the factor of safety. If applied correctly, the shear

strength and thus the factor of safety will have a more realistic

value for F > 1 (when compared to the traditional approach of

using mobilized pore pressure). At F = 1 the two different

approaches coincide.

Two calculation methods for modeling the amount of yield-

induced pore pressure in undrained effective stress LEM

calculations are proposed in the following section. Both

methods employ an anisotropic yield surface to describe the

change of effective mean stress when clay is loaded to failure.

2.2

Method 1: r

u

’

The method r

u

’ was developed for normally consolidated clays.

It should be considered as a simple engineering tool to model

yield-induced pore pressured for stability calculations of old

embankments.

Finnish soft clays are usually only very slightly

overconsolidated, mainly due to aging. Under old embankments

the clays have generally become normally consolidated.

If failure occurs, excess pore pressure will thus have

developed corresponding to a stress change from the initial in

situ state at the K

0NC

line to the failure state. The most critical

event corresponds to slow loading or long loading time allowing

for the yield induced pore pressure to develop. Excess pore

pressure from yielding can now be simply calculated as the

horizontal difference of the intersection of K

0

-line with the

initial yield surface, and the intersection of the failure line with

the yield surface in the (p’, q) stress space. For this a proper

estimation of the yield surface is needed. It has been shown

(Länsivaara 1995, Länsivaara 1999) that the initial yield surface

can be estimated by knowing only the friction angle and the

preconsolidation pressure of the clay.

This can further be utilized by applying a pore pressure

parameter similar to the generally used r

u

, with the exception

that it now stands for yield induced pore pressure and should be

applied to effective vertical stress. This pore pressure parameter

is refe d as r

u

’ and is defined as:

rre

) ,'

(

'

1

'

'

0

0

0

v

v

v

ey

u

f

u

r

(2)

Failure state

Equilibrium state

’

n

’

f

e

fu

Overprediction

of strength