2970

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

working platform over soft soil in Vung Tau in Vietnam using

one metre thick of geocell mattress to support a two metre thick

MSL as a loading platform for the heavy crawler crane exerting

a contact pressure of 500 kPa (Ong et al., 2011). The two

loading platform performances are compared and it is found that

both loading platforms performed satisfactorily with settlement

of less than 50 mm. In 2011, geocell mattress and MSL were

used in another project on soft ground for a container yard in

Gebeng, Kuantan in Malaysia. In this case one metre thick of

geocell mattress were used to support the container pavement of

760 mm thick aggregate base course stabilised with two layers

of TriAx geogrid (MSL) and interlocking paving block finishes.

Figure 1. General condition of working platform without gegorids.

(after Yong, Chan et al., 1990)

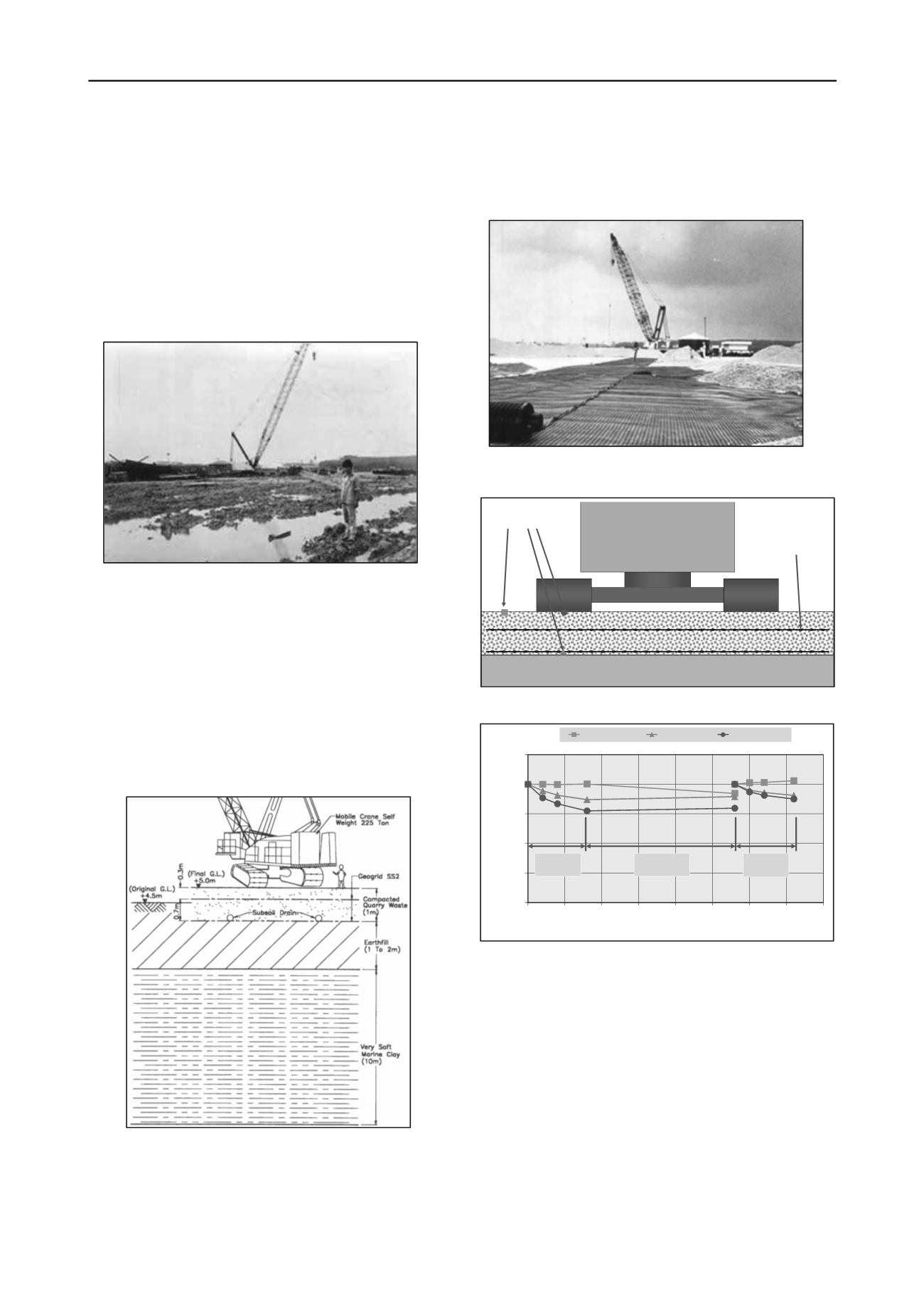

2 PASIR GUDANG FABRICATION YARD

The rehabilitation of the muddy platform started by removing

the top 700 mm of residual soil fill (Figure 2). One layer of the

biaxial geogrid was then placed on top of the compacted clay

fill at excavated level. Backfilling using compacted quarry

waste, a granular material, carried out after suitable subsoil

drains were laid (Figure 3). Another layer of biaxial geogrid

was placed before filling with compacted quarry waste for a

further 300 mm.

Figure 2. Schematic section of rehabilitated working platform.

(after Chan, 2000)

The completed platform formation was tested and at 30

passes of the 2.3 MN crawler crane carrying 700 kN load and

the resulting deformation measured was 37 mm (Chan, 2000),

with decreasing rate of deformation after each pass, which was

acceptable by the fabricator. Settlements on the subgrade and

outside the crane track were measured (Figures 4 & 5). The

rehabilitated fabrication yard was in use after handing over to

the fabricator (Figure 6).

Figure 3. Platform rehabilitation work in progress. (after Yong, Chan

et al., 1990)

2 layers of

geogrid

Measuring

points

230t crane

carrying 70t

load

Soft clay subgrade

Figure 4. Settlement measuring points.

-400

-300

-200

-100

0

100

0

5 10 15 20 25 30 35 40

Settlement (mm)

Number of passes

Edge of track Under track On subgrade

Single

track

Multiple

track

Single

track

Figure 5. Plot of settlement versus number of passes.

3 WORKING PLATFORM IN VUNG TAU

In Vietnam, the geocell mattress with MSL was adopted for the

construction of the working platform for an offshore facilities

fabrication yard in Vung Tau, Vietnam (Ong et al., 2011). The

working platform was required to take loading from heavy

crawler crane tracks up to 50 t/m². The exhibited design uses

conventional reinforced concrete pile-raft foundation system to

support the working platform. However, in order to accelerate

the construction works, alternative solutions using geocell

mattress with MSL was selected not only will it reduce the

construction time but also being more economic and

sustainable. This geocell mattress with MSL was designed to

form a working platform to support the movement of crawler

cranes with 2 m wide and 13.7 m long crane tracks separated by

a clear distance of 7.6 m. The maximum load to be supported on