2960

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

the load shared by the soil, so the differential settlement is

increscent. Because the compressibility of the soil is far greater

than the pile, the settlement of the soil is far larger than the pile,

as a result, the displacement of the soil is downward with

respect to the pile and the downdrag is generated, that is the

negative friction. The larger the load pressure, the greater the

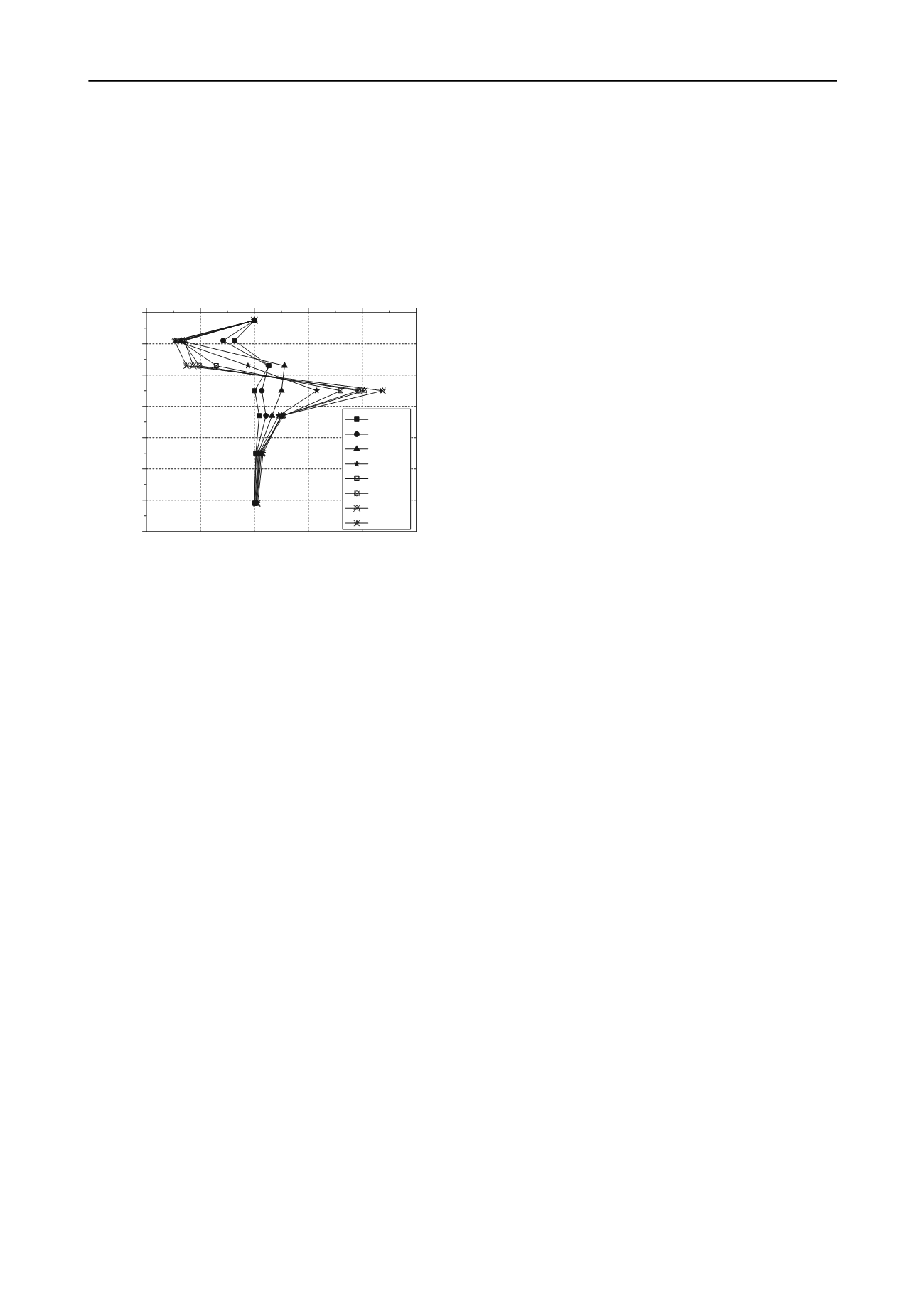

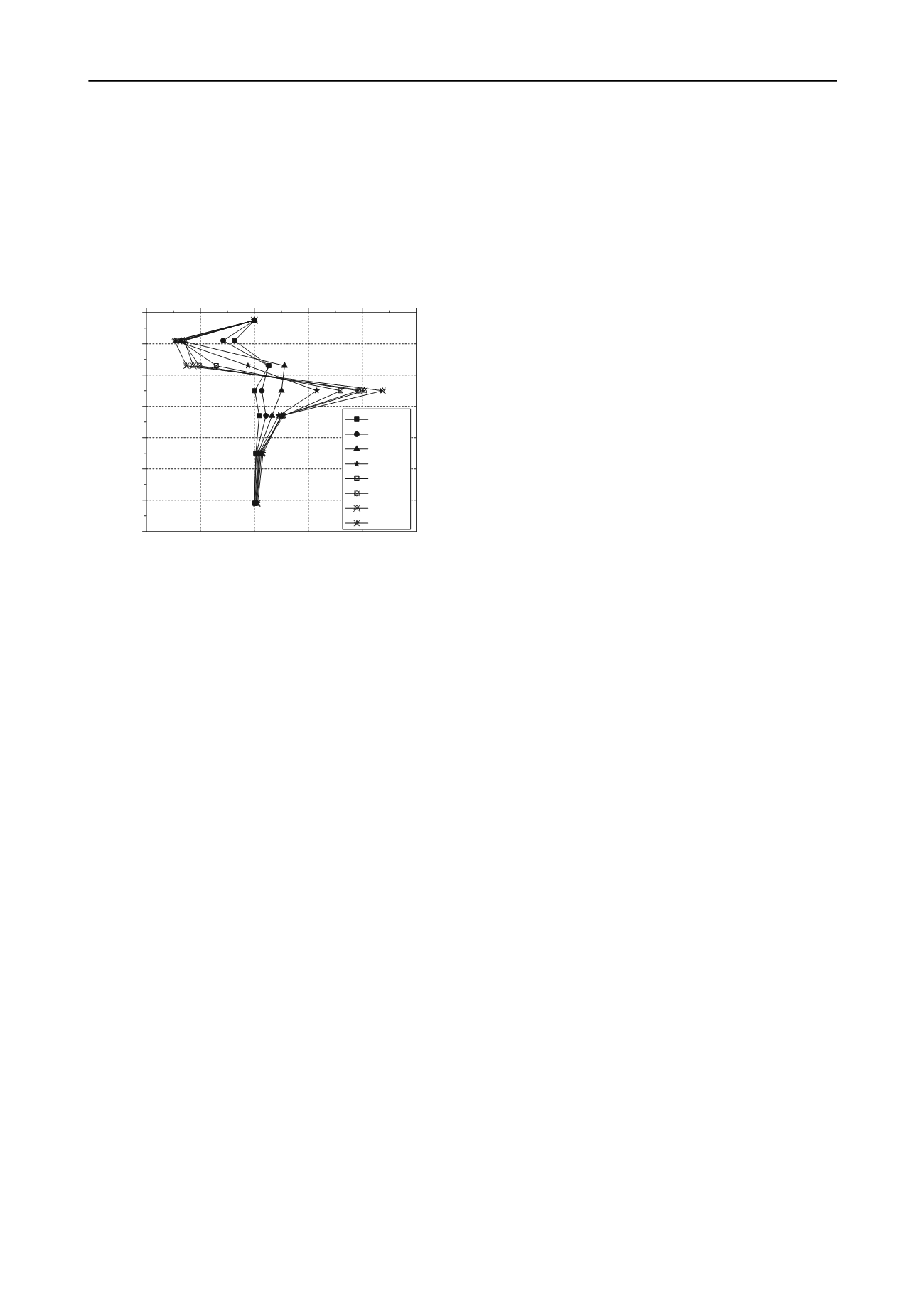

negative friction. The results in Fig. 4 also show that the

location of neutral points is about -2 m, which is almost

unchanged as the increase of the load.

8 REFERENCES

Alzamora, D. E. , Wayne, M. H. , and Han, J. (2000). “Performance of

SRW supported by geogrids and jet grout columns.”

Proc., Sessions

of ASCE Specialty Conf. of Performance Confirmation of

Constructed Geotechnical Facilities

, A. J. Lutenegeer and D. J.

DeGroot, eds., ASCE Geotechnical Special Publication, Reston, Va.,

Vol. 94 , 456–466.

American Association of State Highway Officials/Federal Highway

Administration (2002). Innovative technology for accelerated

construction bridge and embankment foundations, Preliminary

Summary Rep. Prepared for Federal Highway Administration, U.S.

Dept. of Transportation, Washington, D.C.

-7

-6

-5

-4

-3

-2

-1

0

-1000

-500

0

500

1000

1500

Single pile

37 kPa

75 kPa

113 kPa

150 kPa

188 kPa

225 kPa

263 kPa

300 kPa

Friction of pile shaft

f

s

(kPa)

Depth

h

(m)

Arulrajah, A., Abdullah, A., Bo, M. W., and Bouazza, A. (2009).

“Ground improvement techniques for railway embankments.”

Ground Improvement

, 162(1), 3-14.

Arulmoli, A. K., Varatharaj, R. S., Posadas, J., Afewerki, R., Jaradat,

O., and Lim, A. (2010). “Geotechnical challenges associated with

the design of a new marine oil terminal at the port of Los Angeles.”

In:

Ports 2010: Building on the Past, Respecting the Future

Proceedings of the Ports 2010 Conference

, ASCE, Florida, 252-261.

Bakholdin, B. V., Yastrebov, P. I., and Chashchikhina, L. P. (2009).

“Resistance characteristics of soils in the beds of precast piles.”

Soil Mech. Found. Eng.

, 46(2), 39-44.

Chen, R. P., Xu, Z. Z., Chen, Y. M., Ling, D. S., and Zhu, B. (2010

a

).

“Field tests on pile-supported embankments over soft ground.”

J.

Geotech. Geoenviron. Eng.

, 136 (6), 777-785.

Figure 4. The distributions of friction of pile shaft along pile depth

under different vertical load.

Chen, Y. H., Wang, X. Q., Liu, H. L., Jiang, L., and Zhang, T. (2010

b

).

“In-situ study on stress distribution of foundation improved by Y-

section pile.” In:

Ground Improvement Technologies and Case

Histories

, Leung et al. ed., Geotechnical Society of Singapore,

Singapore, 319-330.

6 SUMMARY AND CONCLUSIONS

Based on large-scale load tests and field test of a XCC pile

carried out in this paper, the following conclusions may be

drawn.

Dzhantimirovk, H. A., and Yalaev, R. R. (2009). “Form-free procedure

for fabrication of prestressed piles with no transverse

reinforcement.”

Soil Mech. Found. Eng.

, 46(2), 69-76.

(1) Regarding the contact area of pile-soil interface and EI of

piles, XCC piles can increase these values in comparison to

circular piles for the same amount of concrete volume used. The

large-scale test in a load testing facility indicated that load

carrying capacity of XCC pile exhibit a slightly higher capacity

than circular pile when the same amount of concrete volume

was used. Under the same working load level, XCC pile can be

constructed with less concrete volume and exhibits smaller

settlement when compared to the circular piles.

Eekelen, S. J. M. van, and A. Bezuijen (2008). “Design of piled

embankments, considering the basic starting points of the British

Design Guideline.”

Proc. of EuroGeo 4,

Sep. 2008, Edinburgh UK.

Gniel, J., and Bouazza, A. (2009). “Improvement of soft soils using

geogrid encased stone columns.”

Geotext. Geomembr.

, 27(3), 167-

175.

Han, J., and Gab, M. A. (2002). “Numerical analysis of geosynthetic-

reinforced and pile-supported earth platforms over soft soil.”

J.

Geotech. Geoenviron. Eng.

, 128(1), 44-53.

(2) The X cross section type offers a more reasonable section

form as compared with other traditional pile sections from on

the standpoint of offering contact areas of pile-soil interface and

lateral stiffness. The contact areas of pile-soil interface can be

improved obviously without the increasing of concrete

consumption. XCC pile is also an economic environment new

pile type. With less concrete usage can get the same treatment

effect. In this case study, the maximum values of axial force of

pile shaft is located on the -2 m deep, the location of neutral

points is about -2 m of pile depth.

JGJ94. (2008). “Technical code for building pile foundations.” Beijing,

China Architecture and Building Press. (in Chinese)

Jones, C. J. F. P. , Lawson, C. R. , and Ayres, D. J. (1990). “Geotextile

reinforced piled embankments.”

Proc., 4th Int. Conf. on Geotextiles,

Geomembranes and Related Products

, International Geosynthetics

Society, 155–160.

Lei, G. H. (2001). “Behavior of excavated rectangular piles (barrettes)

in granitic saproletes.” Ph.D. thesis, The Hong Kong University of

Science and Technology, Hong Kong.

Liu, H. L. (2007). “In-situ X-section reinforced concrete pile

construction method.” China patent ZL200710020306.3.

Liu, H. L., Chu, J., and Deng, A. (2009). “Use of large-diameter, cast-in

situ concrete pipe piles for embankment over soft clay.”

Can.

Geotech. J.,

46(7), 915-927.

7 ACKNOWLEDGEMENTS

The authors acknowledge the financial support from the

National Science Joint High Speed Railway Foundation of

China (No. U1134207), and the National Science Foundation of

China (No. 51008116, 51278170).

So, A. K. O., and Ng, C. W. W. (2009). “Performance of long-driven H-

piles in granitic saprolite.”

J. Geotech. Geoenviron. Eng.

,

135(2),

246-258.

Suh, K., Shin, S., and Cox, D. (2006). “Hydrodynamic Characteristics

of Pile-Supported Vertical Wall Breakwaters.”

J. Waterway, Port,

Coastal, Ocean Eng.

, 132(2), 83–96.